How to Estimate the Cost of an Iron Ore Processing Plant?

Laura

Laura

Feb 26, 2025

Feb 26, 2025

18

18

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( 100,000 tpa ultra-pure iron powder production project site )

Estimating the cost of an iron ore processing plant is a critical step for investors and stakeholders in the mining industry. With fluctuating market prices and varying operational requirements, understanding the financial implications of setting up such a facility is essential for informed decision-making. In this article, we will walk you through the key factors to consider when estimating the cost of an iron ore processing plant, along with practical tips and insights.

01 Understanding the Basics of Iron Ore Processing

BackBefore diving into cost estimation, it's important to understand the iron ore processing stages. The primary steps include:

- Crushing and Screening: Initial size reduction of the ore.

- Grinding: Further reduction to liberate iron from impurities.

- Concentration: Separating iron from waste material.

- Pelletizing or Sintering: Preparing iron for smelting.

Each of these stages involves specific equipment and technology, which can significantly impact overall costs.

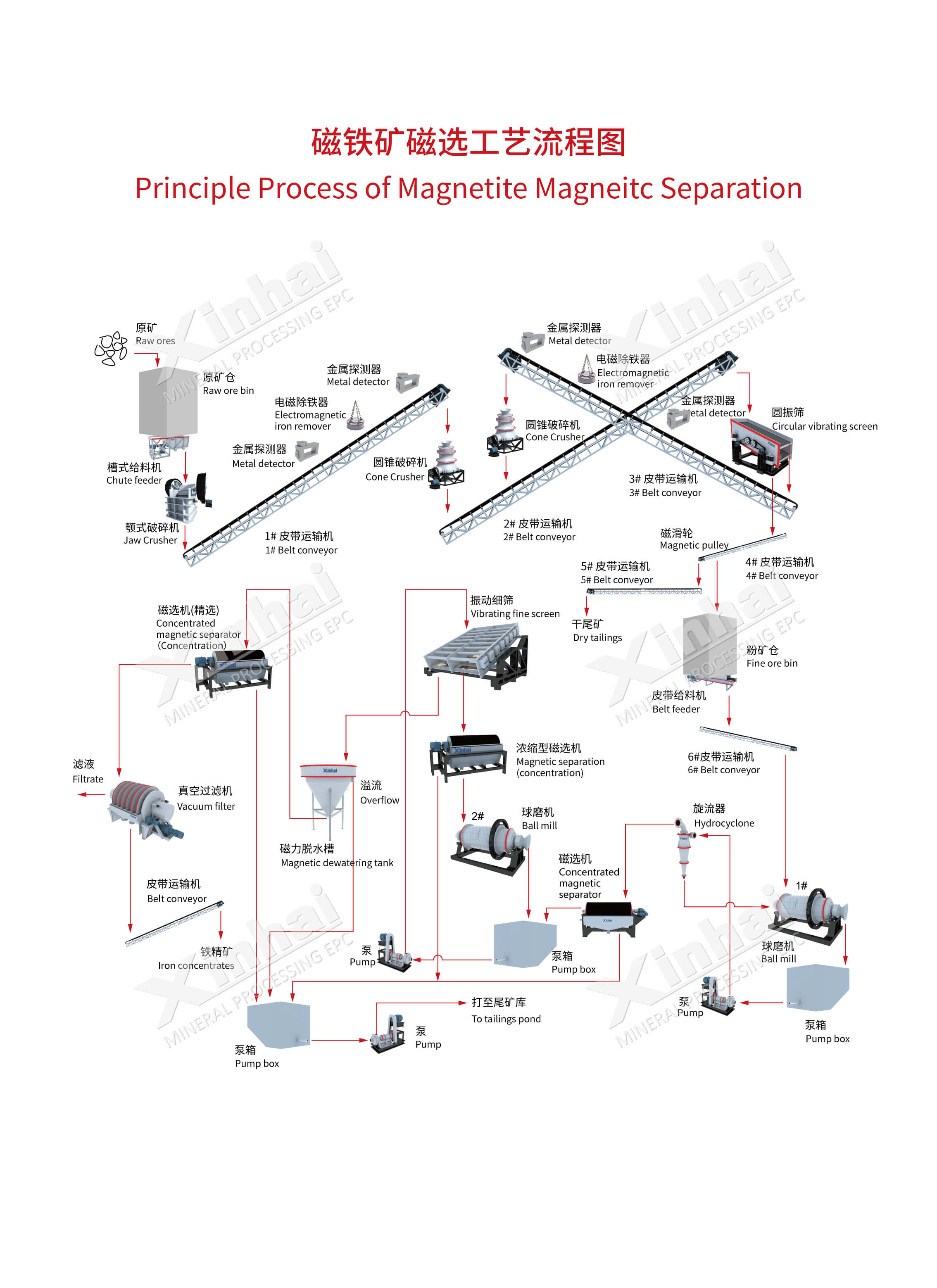

( Magnetite beneficiation - stage grinding + stage magnetic separation production line process flow chart )

02 Key Cost Components

BackEstimating the cost of an iron ore processing plant involves several key components:

A. Capital Expenditure (CapEx)

CapEx includes the initial investment required to set up the plant. This typically covers:

- Land Acquisition: The cost of purchasing or leasing land for the facility.

- Equipment and Machinery: Costs associated with crushers, grinders, separators, and other essential machinery.

- Construction Costs: Expenses related to building the infrastructure, including labor and materials.

- Utilities Setup: Installation of water, electricity, and other necessary utilities.

B. Operational Expenditure (OpEx)

OpEx refers to the ongoing costs of running the plant, which can include:

- Labor Costs: Salaries and wages for employees.

- Maintenance and Repairs: Regular upkeep of equipment to ensure efficiency.

- Material Costs: Expenses for inputs like chemicals and water.

- Energy Costs: Electricity and fuel expenses for operating machinery.

C. Environmental and Regulatory Costs

Compliance with environmental regulations can add significant costs. This may include:

- Permitting Fees: Costs associated with obtaining necessary permits.

- Waste Management: Expenses for handling and disposing of waste materials.

- Environmental Impact Assessments: Costs for studies and assessments to understand the environmental implications of the plant.

03 Estimation Techniques

BackA. Feasibility Studies

Conducting a feasibility study can provide a comprehensive overview of expected costs. This study typically includes market analysis, technical assessments, and financial projections.

B. Benchmarking

Comparing similar projects can help estimate costs. Research industry standards and costs associated with existing iron ore processing plants to gain insights into potential expenses.

C. Detailed Cost Breakdown

Create a detailed cost breakdown based on each component mentioned earlier. This method allows for a clearer understanding of where funds will be allocated and helps identify areas where costs can be optimized.

04 Factors Affecting Cost Estimates

BackSeveral factors can influence the cost of an iron ore processing plant:

- Location: Proximity to ore sources, infrastructure, and markets can affect transportation and operational costs.

- Technology: Advanced processing technologies may require higher initial investments but can lead to lower operational costs in the long run.

- Scale of Operation: Larger plants may benefit from economies of scale, reducing per-unit costs.

- Market Conditions: Fluctuations in iron ore prices and demand can impact the financial viability of the project.

05Conclusion

BackEstimating the cost of an iron ore processing plant is a multifaceted process that requires careful consideration of various factors. By understanding the key components of capital and operational expenditures, utilizing effective estimation techniques, and being aware of influencing factors, stakeholders can make informed decisions. Proper planning and research can lead to a successful project that meets both financial and operational goals.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now