Choosing the Right Mining Slurry Pump: A Comprehensive Guide

Laura

Laura

Jul 31, 2024

Jul 31, 2024

615

615

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

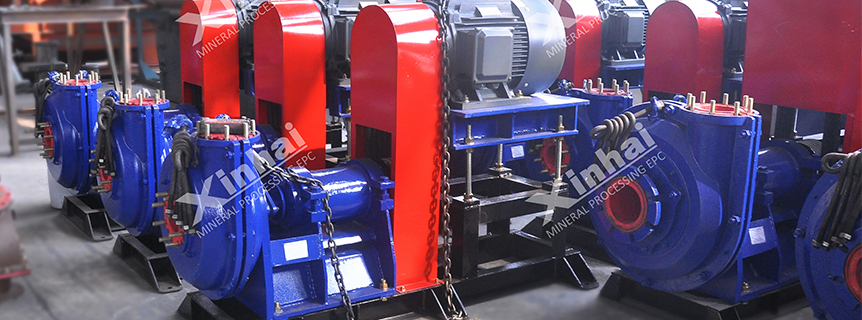

Choosing the Right Mining Slurry Pump

Selecting the appropriate mining slurry pump can significantly impact the efficiency and cost-effectiveness of mining operations. This guide will walk you through the essential aspects of mining slurry pumps, including their definitions, types, applications, and critical features for optimal performance.

01What is a Mining Slurry Pump?

Back1. Definition and Importance

A mining slurry pump is specialized equipment used to transport abrasive and high-density slurries in mining operations. Its importance lies in its ability to handle challenging materials, ensuring effective and continuous material flow in mining sites, processing plants, and tailings management systems.

2. Types of Mining Slurry Pumps

There are several types of mining slurry pumps, each designed for specific applications and materials. The most common types include centrifugal slurry pumps, submersible slurry pumps, and positive displacement slurry pumps. Each type has distinct features; centrifugal pumps are great for handling large volumes, while submersible pumps are ideal for extensive vertical mining environments.

02Applications of Mining Slurry Pumps

Back1. Use in Mineral Processing

In mineral processing, mining slurry pumps are essential for transporting crushed and ground ore from one stage of beneficiation to another. These pumps facilitate the separation of valuable minerals from waste material, ensuring that the processing plants run smoothly and efficiently.

2. Use in Hydraulic Fracturing

Hydraulic fracturing, commonly known as fracking, involves injecting high-pressure fluid into rock formations to extract oil and gas. Mining slurry pumps are used to deliver these high-pressure slurry mixtures, ensuring that the fracturing process is performed effectively and that the materials reach the targeted underground locations.

3. Use in Tailings Management

Tailings management involves the handling and disposal of waste materials generated from mining operations. Mining slurry pumps play a pivotal role in this area, moving the waste slurry to designated storage facilities. Efficient tailings management pumps help minimize environmental impact and comply with strict regulations.

03Key Features of Efficient Mining Slurry Pumps

Back1. Abrasion Resistance

Abrasion resistance is a critical feature in mining slurry pumps because the pumping media often contain sharp and abrasive particles. Pumps with high abrasion-resistant materials, such as high-chrome alloys or rubber-lined components, have a longer lifespan and require less frequent maintenance.

2. High Pressure Handling

An efficient mining slurry pump should effectively handle high pressure without compromising performance. This is particularly important in applications such as hydraulic fracturing, where the slurry needs to be pumped at high pressures. Pumps designed to withstand high pressures ensure reliable operation and improved safety.

3. Durability and Longevity

Durability and longevity are essential features of mining slurry pumps, given the harsh working conditions they operate under. Pumps with robust construction and high-quality materials ensure they can endure the rigors of mining environments, reducing downtime and associated costs.

04Installation and Maintenance Guidelines

Back1. Proper Selection and Installation Techniques

Proper selection and installation of a mining slurry pump are crucial for optimal performance and longevity. Matching the pump specifications to the application requirements is essential, taking into account factors such as flow rate, pressure, and the nature of the slurry. Correct installation practices, including precise alignment and secure mounting, play a significant role in minimizing operational issues and extending pump life.

2. Regular Maintenance Tips

Regular maintenance of mining slurry pumps involves inspections and timely servicing to prevent unexpected breakdowns. It is vital to regularly check and replace wear parts, such as impellers and liners, to ensure continuous optimal operation. Lubrication of moving parts and monitoring for signs of corrosion or damage should also be part of routine maintenance practices to maintain pump efficiency.

3. Common Troubleshooting Methods

Troubleshooting common issues with mining slurry pumps requires a systematic approach to identify and resolve problems. Common issues include loss of flow, abnormal noises, and overheating. Addressing these through checking for blockages, inspecting seals and bearings, and ensuring proper lubrication can help resolve most issues and restore the pump to full functionality.

05Factors to Consider When Choosing a Mining Slurry Pump

Back1. Material Composition

Material composition is a critical factor when selecting a mining slurry pump, as it must withstand the corrosive and abrasive nature of the slurry. High-chrome alloys and rubber linings are typically favored materials for their resilience to wear and tear. The compatibility of pump materials with the slurry components ensures prolonged operational life and reduced maintenance costs.

2. Flow Rate Requirements

Understanding flow rate requirements is essential for choosing a mining slurry pump that meets the application needs. The flow rate must align with the volume and speed at which the slurry needs to be transported. Incorrect flow rate specifications can lead to inefficiencies, increased wear, and potential damage to the pump, resulting in increased operational costs and downtime.

3. Environmental Conditions

Environmental conditions, including temperature, humidity, and altitude, can significantly impact the performance of a mining slurry pump. Pumps designed to operate under specific environmental conditions ensure reliable performance and durability. For instance, pumps used in high-temperature environments should have components that can withstand heat, while those in high-humidity areas should be corrosion-resistant to avoid rust and degradation.

06Benefits of Using Advanced Mining Slurry Pumps

Back1. Improved Efficiency

Advanced mining slurry pumps are designed with superior engineering to enhance efficiency in mining operations. These pumps typically feature advanced hydraulic designs and optimal internal components that reduce energy consumption and improve slurry handling capabilities, leading to more streamlined operations and cost savings.

2. Reduced Down Time

One of the primary advantages of using advanced mining slurry pumps is the reduction in downtime due to enhanced durability and reliability. These pumps are built with robust materials and cutting-edge technology, minimizing the frequency of breakdowns and maintenance requirements. This leads to more uninterrupted operation and fewer disruptions in mining activities.

3. Cost-Effectiveness

While advanced mining slurry pumps may have a higher initial investment, their long-term cost-effectiveness is significantly higher. The reduced energy consumption, lower maintenance costs, and extended lifespan contribute to overall financial savings. Additionally, the improved efficiency and reduced downtime translate to increased productivity, maximizing the return on investment.

07Summary

BackChoosing the right mining slurry pump involves a thorough understanding of the equipment's specifications, applications, and operational requirements. Efficient pumps with the right features, proper installation and maintenance, and consideration of material, flow rate, and environmental factors ensure optimal performance. Advanced pumps offer substantial benefits, improving efficiency, minimizing downtime, and providing cost-effective solutions for mining operations. With careful selection and ongoing maintenance, mining slurry pumps can significantly enhance the productivity and sustainability of mining projects.

Contact us and learn more about mining slurry pump!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now