The Ultimate Guide on How to Leach Gold from Ores

Laura

Laura

Sep 17, 2024

Sep 17, 2024

2922

2922

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Myanmar 500tpd gold CIL plant project site

Gold has always been a symbol of wealth, power, and beauty. Its allure has driven countless individuals and civilizations to seek it out, often leading to some of the most significant advancements in mining and metallurgy. One of the primary methods for extracting gold from its ores is leaching. In this comprehensive guide, we will delve into the intricacies of gold leaching, covering everything from the science behind the process to practical applications and safety considerations.

01Understanding Gold Ores

BackBefore we dive into the leaching process, it is essential to understand what gold ores are. Gold ores are naturally occurring rocks or minerals that contain gold in sufficient quantities to make extraction economically viable. These ores can vary widely in their composition, often containing other metals such as silver, copper, and iron. The presence of these other metals can complicate the extraction process, making it necessary to choose the right leaching method.

1. Free-Milling Ores

These are ores that contain gold in a form that is easily recoverable through standard processing methods. Free-milling ores usually have a gold content of 1 gram per ton or higher.

2. Refractory Ores

These ores are more challenging to process because the gold is locked within other minerals and cannot be released through conventional methods. Refractory ores often require more advanced techniques, such as bioleaching or pressure oxidation.

3. Complex Ores

These ores contain multiple metals and minerals, making the extraction process more complicated. They may require a combination of leaching methods and additional processing steps.

02The Science of Gold Leaching

BackLeaching is a hydrometallurgical process that involves the dissolution of metals from their ores using chemical solvents. In the case of gold extraction, the most common leaching agents are cyanide solutions, although alternative methods using thiosulfate, chlorine, or even biosolutions are gaining popularity.

1. The Cyanide Process

Cyanide leaching is the most widely used method for gold extraction. The process involves the following steps:

1). **Preparation of the Ore**: The ore is crushed and ground to liberate the gold particles from the surrounding rock. This increases the surface area for the leaching solution to act upon.

2). **Cyanidation**: The ground ore is then mixed with a dilute cyanide solution. The cyanide ions (CN⁻) react with the gold (Au) to form a soluble gold-cyanide complex.

3). **Separation**: After a specified period, the gold-cyanide solution is separated from the remaining ore material. This can be done using methods such as filtration or sedimentation.

4). **Recovery**: The gold is then recovered from the solution through various methods, including carbon adsorption, electrowinning, or precipitation with zinc dust.

2. Alternative Leaching Methods

While cyanide leaching is the most common method for gold extraction, it is not without its drawbacks, particularly concerning environmental and safety issues. As a result, researchers and miners have explored alternative leaching methods:

1). **Thiosulfate Leaching**: This method utilizes thiosulfate ions as a leaching agent, offering a less toxic alternative to cyanide.

2). **Chlorine Leaching**: Chlorine gas can be used to dissolve gold in a solution of hydrochloric acid. This method is more expensive and complex but can be effective, particularly for refractory ores.

3). **Biosolutions**: Researchers are exploring the use of bacteria and other microorganisms to leach gold from ores. This environmentally friendly approach can be particularly useful for low-grade ores.

03The Leaching Process: Step-by-Step

BackNow that we understand the science behind gold leaching, let's break down the process into a detailed, step-by-step guide.

Step 1: Ore Preparation

- **Crushing**: The first step in the leaching process is to crush the ore to a manageable size. This is typically done using jaw crushers or cone crushers.

- **Grinding**: After crushing, the ore is ground to a fine powder using ball mills or rod mills. The goal is to liberate the gold particles from the surrounding rock.

- **Concentration**: In some cases, it may be beneficial to concentrate the gold using methods such as gravity separation or flotation before leaching.

Step 2: Leaching

- **Choosing the Leaching Agent**: Depending on the type of ore and the desired recovery method, select the appropriate leaching agent (e.g., cyanide, thiosulfate, or chlorine).

- **Preparing the Leaching Solution**: Prepare the leaching solution by dissolving the leaching agent in water. Ensure that the solution is at the proper concentration for effective leaching.

- **Mixing**: Combine the prepared ore with the leaching solution in a leaching tank. The mixture is agitated to promote contact between the ore and the leaching agent.

- **Monitoring**: During the leaching process, monitor the pH, temperature, and concentration of the leaching agent. Adjust as necessary to optimize gold recovery.

Step 3: Separation

- **Settling**: After the leaching period (which can range from a few hours to several days), allow the solids to settle. This can be done in a settling tank or by using a clarifier.

- **Filtration**: Separate the liquid gold-cyanide solution from the solid waste using filtration methods such as vacuum filtration or pressure filtration.

Step 4: Gold Recovery

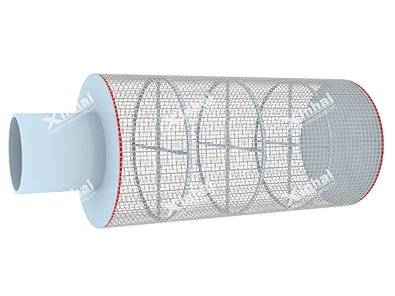

- **Carbon Adsorption**: One common method of recovering gold from the leaching solution is to use activated carbon. The gold-cyanide complex adsorbs onto the carbon, which can then be separated from the solution.

- **Electrowinning**: In this method, an electric current is passed through the solution, causing gold to deposit onto the cathode. The gold can then be stripped from the cathode for further refining.

- **Precipitation**: Another recovery method involves adding zinc dust to the leaching solution, which causes gold to precipitate out of the solution. The resulting sludge can then be filtered and processed.

Step 5: Refining

After recovering the gold, it may still contain impurities. The final step is refining the gold to achieve a high level of purity.

- **Smelting**: The gold concentrate can be smelted in a furnace to remove impurities. Fluxes such as borax or soda ash are often added to help separate the gold from other metals.

- **Chemical Refining**: For even higher purity, chemical refining methods such as the Miller process (using chlorine gas) or the Wohlwill process (using electrolysis) can be employed.

04Safety and Environmental Considerations

BackGold leaching, especially with cyanide, poses significant safety and environmental risks. It is crucial to implement strict safety measures and adhere to environmental regulations to minimize these risks.

1. Safety Precautions

1). **Personal Protective Equipment (PPE)**: Workers should wear appropriate PPE, including gloves, goggles, and respirators, to protect against exposure to toxic chemicals.

2). **Training**: Employees should be trained in the safe handling of chemicals, emergency response procedures, and first aid.

3). **Ventilation**: Ensure that leaching areas are well-ventilated to prevent the accumulation of toxic gases.

2. Environmental Considerations

1). **Waste Management**: Properly manage and dispose of waste materials generated during the leaching process. This includes tailings, which can contain residual chemicals.

2). **Water Management**: Implement systems to prevent leachate from contaminating local water sources. This may involve constructing containment ponds or treatment facilities.

3). **Monitoring**: Regularly monitor the environmental impact of leaching operations, including soil and water quality assessments.

05Conclusion

BackGold leaching is a complex yet fascinating process that has evolved significantly over the years. Understanding the science behind leaching, the different methods available, and the necessary safety and environmental considerations is crucial for anyone interested in gold extraction.

Whether you are a small-scale miner or a large-scale operation, mastering the leaching process can lead to successful and sustainable gold recovery. As technology advances and new methods are developed, the future of gold extraction looks promising, with an increasing focus on minimizing environmental impact while maximizing recovery efficiency.

In your journey to leach gold from ores, remember to prioritize safety, adhere to best practices, and stay informed about the latest advancements in the field. Happy mining!

Contact us and learn more on How to Leach Gold.

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Message

Message Chat Now

Chat Now