8 Gold Extraction Methods and Their Suitable Ore Types

Star

Star

May 29, 2022

May 29, 2022

4502

4502

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

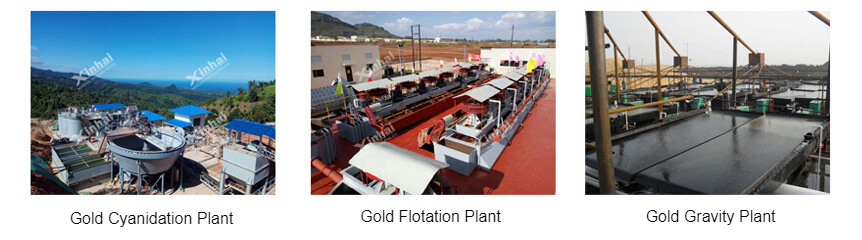

(Indonesia 100TPD gold ore cyanidation plant)

Due to the different properties of gold ore, there are many extraction methods. The right method can maximize the beneficiation recovery rate. This article will introduce 8 gold extraction methods and the types of ore they are suitable for to you.

01 Single Amalgamation

BackThe single amalgamation method is suitable for high-grade quartz primary ores or oxidized ores containing coarse-grained gold. But the amalgamation method cannot fully recover the fine-grained gold. Therefore, the tailings should be properly preserved for later disposal. And the method is simple in structure, low in investment and quick in effect.

02 Single Flotation

BackThe single flotation method is suitable for the extraction of fine gold particles, sulfide gold-bearing quartz vein ore with good floatability, and gold-bearing sulfide ore containing various valuable metals such as copper, lead, and zinc. During flotation, gold and other metal sulfides are enriched into the concentrate, and the tailings are directly discarded.

03 Direct Cyanidation

BackIt is suitable for processing gold ore produced in quartz veins in a fine-grained dispersion state and gold ore with a high degree of oxidation and no the element like copper, arsenic, antimony, bismuth and carbon. Direct cyanidation has the advantages of less cyanide consumption, high leaching rate, good productivity and easy control. However, the use of direct cyanidation process requires higher fineness of materials, which causes large power consumption and high infrastructure investment. More posts about gold cyanidation.

04 Amalgamation - Gravity or Gravity - Amalgamation

BackThe amalgamation-gravity separation method is suitable for the extraction of simple quartz vein gold-bearing sulfide ore. First, the amalgamation method is used to recover coarse gold, and then gravity separation is used to wash the gold-bearing heavy metal sulfide concentrate;

Gravity-mercury amalgamation is suitable for treating oxidized coarse gold or contaminated coarse gold, as well as placer gold ores with low gold content. The heavy sand is obtained by gravity separation first, and then treated by amalgamation.

05 Gravity - Cyanidation

BackGravity-cyanidation is suitable for the treatment of gold-bearing oxide ore in quartz veins. The crude ore is washed by gravity separation to obtain rough concentrate, which is then treated by cyanidation.

06 Amalgamation - Flotation

BackFirst, the amalgamation method is used to recover the coarse-grained gold in the original ore, and the tailings are sent to the next stage of flotation. In addition to processing ores suitable for single flotation, it is also suitable for processing gold-bearing oxide ores and associated free gold ores. The beneficiation index obtained by this process is higher than that of the single flotation process.

07 Flotation - Gravity Separation

BackFlotation-gravity separation is suitable for processing ores in which gold and sulfide coexist closely and can only be recovered by smelting methods. The flotation-gravity separation process is mainly based on flotation, this is the main steps of gold flotation, and the purpose of gravity separation is to recover a small amount of difficult-to-float sulfide (mostly pyrrhotite) in the tailings to improve the total recovery rate of gold.

08 Flotation - Cyanidation

BackAccording to the specific process, the flotation-cyanidation method can be subdivided into the following three methods:

(1) Flotation - Concentrate Cyanidation

It is suitable for processing quartz-pyrite ore and quartz vein gold-bearing ore in which gold and sulfide are closely coexisted. The flotation concentrate continues to be processed with cyanidation. Cyanide tailings abandoned. Compared with the direct cyanidation method, in the flotation-concentrate cyanidation method, the gold ore does not need to be all finely ground, which saves power, floor space and capital investment.

(2) Flotation - Tailings Cyanidation

It is suitable for processing gold-copper ores containing various sulfides. Because these ores contain minerals that are not conducive to cyanidation, if they are removed by flotation first, and the flotation products are treated with special methods, and then the flotation tailings are treated with cyanidation, better results can be obtained. recycling index.

(3) Flotation - Roasting - Cyanidation

It is suitable for processing gold-pyrite with high sulfide content and insoluble arsenic- and antimony-containing composite gold ores. The flotation concentrate is roasted to remove harmful cyanide arsenic, antimony, etc., thereby improving the cyanide leaching index.

09To wrap up

BackThe above is an introduction to the 8 gold extraction methods and the types of ore they are suitable for. Mine owners can choose the appropriate gold extraction method according to the ore properties.

If you want to customize the gold extraction process, you can contact customer service or leave a message, and we will give you feedback as soon as possible.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now