Antimony Processing: Unlocking the Potential of a Versatile Element

Essow

Essow

Mar 20, 2024

Mar 20, 2024

4395

4395

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Antimony, a lustrous gray metalloid with various industrial applications, has been known to mankind for centuries. With its unique properties and diverse uses, antimony has become an essential element in fields ranging from metallurgy to electronics. This article explores the fascinating world of antimony processing, shedding light on its extraction, refining, and applications. Understanding the methods and advancements in antimony processing is crucial for industries that rely on this versatile element to drive innovation and meet evolving market demands.

(Antimony Ore)

01 Industrial Applications

BackAntimony finds a wide range of applications across diverse industries due to its unique properties. In the metallurgical sector, antimony is used as an alloying element to improve the properties of lead, tin, and other metals. Antimony alloys, such as antimonial lead and Britannia metal, have applications in batteries, ammunition, and soldering. Antimony trioxide, a common compound derived from antimony, is utilized as a flame retardant in plastics, textiles, and electronics.

Furthermore, antimony's semiconducting properties make it valuable in the electronics industry, where it is used in the production of diodes, infrared detectors, and photovoltaic devices. Its ability to form alloys with other metals also makes it useful in manufacturing bearings, bullets, and cable sheaths. In the chemical industry, antimony compounds serve as catalysts in the production of polyester and polyethylene terephthalate (PET) plastics.

Antimony has a wide range of industrial applications due to its unique properties. Here are some of the major industrial applications of antimony:

1. Flame Retardants

Antimony compounds, particularly antimony trioxide (Sb2O3), are widely used as flame retardants in various materials. They act as synergists, enhancing the flame-retardant properties of other substances. Antimony trioxide is commonly used in plastics, textiles, coatings, and electrical devices to reduce the flammability and slow down the spread of fires.

2. Batteries

Antimony finds application in lead-acid batteries, which are commonly used in automotive and industrial applications. Antimony is added to the lead grids of the battery to improve their mechanical strength and durability. It also contributes to the formation of a stable oxide layer on the positive plate, enhancing battery performance and lifespan.

3. Alloys

Antimony is used as an alloying element in various alloys. One of the most notable applications is in lead alloys. Antimony-lead alloys provide improved hardness, strength, and resistance to corrosion, making them suitable for applications such as ammunition, automotive batteries, and construction materials.

Antimony is also used in the production of type metal, which is an alloy used for printing and typesetting. The addition of antimony to lead produces a harder and more durable type metal.

4. Glass and Ceramics

Antimony compounds are employed in the glass and ceramics industry. Antimony oxide (Sb2O3) acts as a decolorizing agent in glass manufacturing, helping to remove the green or yellow tint caused by iron impurities. It is also used in the production of opalescent glass, which displays a milky or iridescent appearance.

Antimony compounds are utilized in the production of ceramic glazes, providing desired colors and opacities to the finished products.

5. Electronics

Antimony is used in certain electronic applications, primarily as a dopant in semiconductors. By introducing antimony into semiconductor materials such as silicon or germanium, the electrical properties can be modified to create p-type (positive) conductivity.

6. Catalysts

Certain antimony compounds, such as antimony pentoxide (Sb2O5), act as catalysts in various chemical reactions. They are used in the production of polyester fibers, polyethylene terephthalate (PET) resins, and the manufacturing of polyethylene terephthalate (PET) bottles.

7. Pigments

Antimony compounds are utilized as pigments in paints, coatings, and plastics. Antimony-based pigments, such as antimony vermilion (Sb2S3), provide bright red or orange colors and good lightfastness properties.

8. Medical Applications

Antimony compounds, such as antimony potassium tartrate (tartar emetic), have been used in the past for medicinal purposes. However, their use in medicine has significantly declined due to potential toxicity concerns.

02 Extraction Methods

BackThe primary sources of antimony extraction are stibnite (antimony trisulfide) and valentinite (antimony trioxide). The extraction process typically involves several steps, including mining, concentration, and smelting. Mining involves the extraction of antimony-rich ore from underground or open pit mines. Once mined, the ore is then concentrated using techniques like gravity separation or flotation to increase its antimony content. The concentrated ore is further processed through smelting, where it is heated in a furnace to separate antimony from other impurities, resulting in antimony metal or antimony oxide, depending on the intended application.

Concentration techniques play a crucial role in increasing the antimony content in the ore before smelting. Here are some commonly employed concentration techniques for antimony extraction:

1. Gravity Separation

Gravity separation is a widely used method for antimony concentration. It exploits the difference in density between the antimony minerals and the gangue (non-valuable minerals) to achieve separation. The principle behind gravity separation is simple: heavier particles settle faster than lighter particles.

In gravity separation, the ore is subjected to water or air currents, allowing the heavier antimony minerals to settle while the lighter gangue particles are washed away. Equipment such as jigs, shaking tables, and spirals are utilized to enhance the separation process. The choice of equipment depends on the particle size, ore characteristics, and desired antimony concentration.

2. Flotation

Flotation is another commonly employed technique in antimony concentration. It relies on the selective attachment of chemicals to the antimony minerals, enabling their separation from the gangue.

The flotation process starts with grinding the ore into a fine powder. The ground ore is mixed with water and chemicals known as collectors, which selectively attach to the antimony minerals. Frothers are also added to create a froth layer that stabilizes the mineral bubbles.

Air is then introduced into the flotation cell, causing the antimony minerals to float to the surface as a froth, while the gangue particles remain in the slurry. The antimony-rich froth is collected and further processed to obtain a concentrated antimony product.

(Flotation Machines)

3. Hydrometallurgical Techniques

Hydrometallurgical techniques involve the use of aqueous solutions to extract antimony from its ores. These techniques are often employed for low-grade ores or complex ore compositions.

Leaching is a common hydrometallurgical method used for antimony concentration. It involves the extraction of antimony from the ore by dissolving it in a suitable solvent or leachate. Various leaching agents, such as acidic or alkaline solutions, are used depending on the ore characteristics.

Solvent extraction is another hydrometallurgical technique used to concentrate antimony. It involves extracting antimony from a leachate solution using an organic solvent. The antimony is selectively transferred from the aqueous phase to the organic phase, allowing for separation and concentration.

4. Magnetic Separation

Magnetic separation is employed in some cases to concentrate antimony minerals. This technique is based on the magnetic properties of certain minerals. By applying a magnetic field to the ore, the antimony-bearing minerals can be attracted to the magnetic surface, separating them from the non-magnetic gangue.

Magnetic separation is particularly useful for separating antimony minerals that exhibit strong magnetic properties, such as stibnite.

It's important to note that the choice of concentration technique depends on factors such as the ore composition, particle size, and desired antimony concentration. Often, a combination of techniques is employed to maximize the recovery of antimony from the ore.

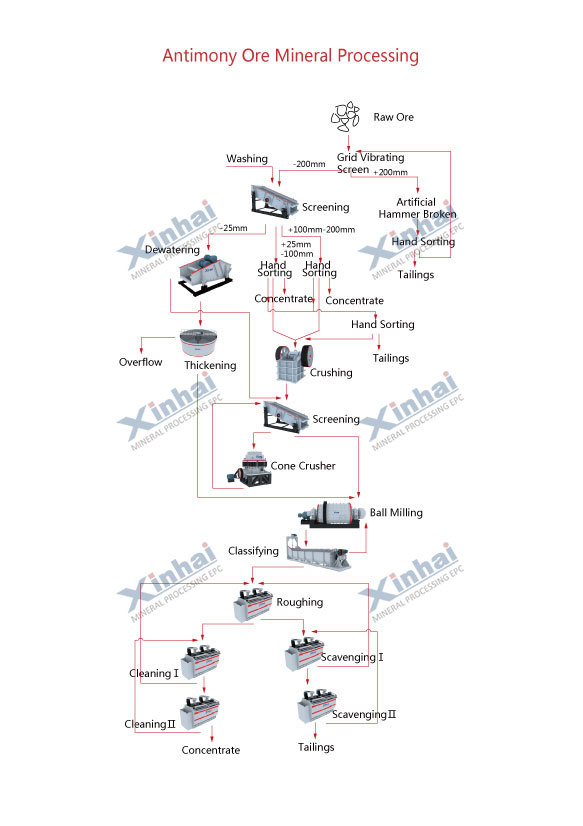

(Antimony Extraction Flowchart)

03 Refining Techniques

BackRefining techniques are employed to further purify and process antimony after it has been extracted from its ore. These techniques aim to remove impurities and obtain high-purity antimony products suitable for specific applications. Here are some commonly used refining techniques in antimony processing:

1. Pyrometallurgical Refining

Pyrometallurgical refining involves the use of high temperatures to separate impurities from antimony. The primary pyrometallurgical refining method used for antimony is called liquation.

Liquation involves heating impure antimony in a furnace to a temperature just below its melting point. As the antimony melts, impurities with lower melting points, such as sulfur and arsenic, tend to separate and rise to the surface in the form of dross. The dross is then skimmed off, leaving behind purified antimony.

2. Electrorefining

Electrorefining is an electrochemical technique used to refine impure antimony through the application of an electric current. This method is similar to electrolysis and is commonly employed in the refining of metals.

In electrorefining, impure antimony is dissolved in a suitable electrolyte solution, and electrodes are immersed in the electrolyte. When an electric current is applied, antimony ions migrate from the impure anode to the cathode, where they are deposited as pure antimony. The impurities remain in the anode or settle as a sludge, allowing for their removal and separation from the refined antimony product.

3. Hydrometallurgical Refining

Hydrometallurgical refining techniques utilize chemical reactions in aqueous solutions to purify antimony. These techniques are often employed for treating impure antimony concentrates or recycling antimony-containing materials.

One common hydrometallurgical refining method is called leaching. Leaching involves dissolving impure antimony in a suitable solvent or leachate, which selectively dissolves the impurities while leaving the antimony behind. The solution is then separated, and the antimony can be precipitated or recovered through processes such as solvent extraction or precipitation.

4. Zone Refining

Zone refining is a specialized refining technique used to obtain extremely high-purity antimony. It is a time-consuming and costly method but yields highly purified products.

In zone refining, a small rod of impure antimony is heated at one end, causing the impurities to migrate along the rod. As the impurities move, a molten zone forms and progresses along the rod. By repeatedly passing the molten zone over the antimony rod, impurities are gradually pushed to one end and removed. The result is a highly purified antimony rod.

5. Recycling and Recovery

Recycling and recovery techniques play an essential role in refining antimony from various secondary sources, such as antimony-containing scrap materials or residues from other processes. These techniques involve processes like smelting, leaching, or hydrometallurgical methods to extract antimony from the secondary sources and refine it into usable forms.

By employing refining techniques, impurities are minimized, and high-purity antimony products are obtained. The choice of refining method depends on factors such as the impurity content, the desired purity level of the final product, and the specific requirements of the intended application.

04 Environmental Considerations

BackAlthough antimony offers numerous advantages, it is important to consider its environmental impact. Antimony mining and processing can result in the release of antimony-rich dust, which may pose health risks to nearby communities. Strict regulations and proper waste management practices are necessary to minimize environmental contamination. Additionally, efforts are underway to develop more sustainable antimony extraction and refining processes, such as using cleaner technologies and recycling methods.

05 Future Trends

BackAs industries continue to evolve, the demand for antimony is expected to rise. Research and development efforts are focused on enhancing antimony processing techniques, optimizing its use in various applications, and exploring new possibilities. Furthermore, the shift towards sustainable practices and environmental consciousness is likely to shape the future of antimony processing, ensuring its responsible utilization.

06Conclusion

BackIn conclusion, antimony processing plays a vital role in unlocking the potential of this versatile element. From its historical significance to modern-day applications, antimony continues to contribute to numerous industries, ranging from metallurgy to electronics. As technology advances and environmental concerns take center stage, it becomes imperative to develop efficient and sustainable methods for antimony extraction, refining, and utilization. By doing so, we can harness the full potential of antimony while ensuring a greener and more responsible approach to its processing.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now