How Much Does It Cost to Set Up a Silica Sand Processing Plant?

Laura

Laura

Feb 27, 2025

Feb 27, 2025

2827

2827

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Quartz sand beneficiation plant site )

Setting up a silica sand processing plant is a significant investment, especially for entrepreneurs looking to tap into the growing demand for silica sand in various industries, including construction, glass manufacturing, and hydraulic fracturing. But how much does it actually cost to establish such a facility? In this article, we will break down the key factors that influence the overall costs, helping you make informed decisions.

01 Understanding Silica Sand Processing

BackBefore diving into costs, it's essential to understand what silica sand processing entails. Silica sand, primarily composed of quartz, is processed to remove impurities and enhance its quality for various applications. The processing typically includes:

1). Mining: Extracting silica sand from the earth.

2). Washing: Removing clay, silt, and other impurities.

3). Screening: Sorting the sand into different grades.

4). Drying: Reducing moisture content.

5). Packaging: Preparing the sand for shipping.

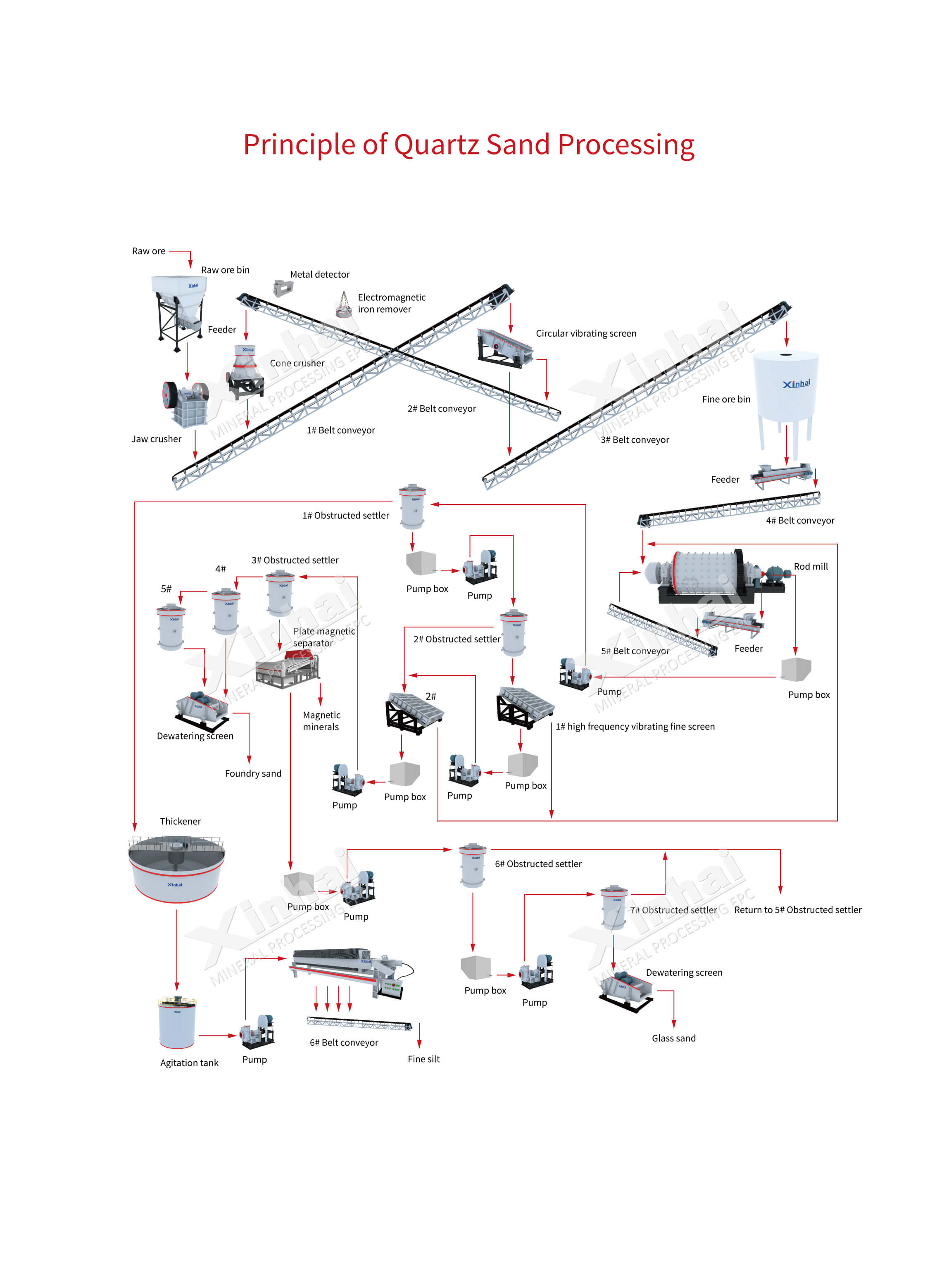

( Quartz sand dressing plant process flow )

02 Key Cost Factors

BackThe total cost of setting up a silica sand processing plant can vary widely based on several factors:

1). Location

The geographical location of your plant plays a crucial role in costs. Areas close to silica sand deposits may reduce transportation expenses. However, costs can vary significantly based on local regulations, labor costs, and availability of resources.

2). Land Acquisition

Purchasing or leasing land for your processing plant can be a major expense. The size of the land required will depend on the scale of your operations. Consider factors like zoning regulations and proximity to raw materials and markets.

3). Equipment and Machinery

Investing in the right equipment is essential for efficient processing. This may include:

- Excavators: For mining silica sand.

- Washing systems: To clean the sand.

- Screening machines: For sorting.

- Dryer: To reduce moisture.

- Conveyors and packaging machines: For transport and distribution.

The cost of this equipment can range from tens of thousands to several million dollars, depending on the scale and technology used.

4). Labor Costs

Hiring skilled labor is vital for operating the plant. Labor costs vary by region and depend on the number of employees needed for mining, processing, maintenance, and administration. Consider both salaries and benefits when calculating labor costs.

5). Utilities and Operating Expenses

Your processing plant will require utilities such as water, electricity, and gas. These ongoing operating expenses should be factored into your budget. Additionally, maintenance costs for equipment and facilities need consideration.

6). Permits and Regulatory Compliance

Setting up a silica sand processing plant involves adhering to environmental regulations and obtaining the necessary permits. Costs for these permits can vary significantly based on local laws and the complexity of your operations.

7). Marketing and Distribution

Once you have processed the silica sand, you'll need to market and distribute your product. This includes branding, packaging, and logistics costs, which can add to your overall investment.

03 Estimated Cost Breakdown

BackWhile the total cost can vary, here’s a rough estimate to give you an idea of what to expect:

- Land Acquisition: $50,000 - $500,000

- Equipment and Machinery: $500,000 - $2 million

- Labor Costs (annual): $100,000 - $500,000

- Utilities (annual): $20,000 - $100,000

- Permits and Compliance: $10,000 - $100,000

- Marketing and Distribution: $20,000 - $100,000

Total Estimated Cost: $700,000 - $3.4 million

04Conclusion

BackSetting up a silica sand processing plant is a complex endeavor that requires careful planning and significant investment. Costs can vary widely based on location, equipment, labor, and regulatory requirements. By understanding these factors and conducting thorough market research, you can create a realistic budget and increase your chances of success in this lucrative industry. Always consult with industry experts and financial advisors to ensure that you’re making informed decisions tailored to your specific situation.

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Message

Message Chat Now

Chat Now