Graphite Ore Beneficiation Process: An Overview

Shirley

Shirley

Apr 15, 2023

Apr 15, 2023

1445

1445

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

01Introduction

BackGraphite, a naturally occurring form of crystalline carbon, is a valuable mineral resource due to its unique properties such as high electrical and thermal conductivity, resistance to chemical reactions, and excellent lubricating capabilities. As a result, graphite finds a wide range of applications in industries such as batteries, lubricants, and advanced composite materials. This document provides an overview of the graphite ore beneficiation process, focusing on the key elements involved in transforming the raw material into a valuable industrial resource.

02Graphite Ore Characteristics

BackGraphite ore is typically found in two forms: flake graphite and vein (or lump) graphite. Flake graphite occurs as flat, plate-like crystalline structures, while vein graphite is characterized by its fibrous, vein-like texture. The beneficiation process aims to increase the purity and quality of the graphite, making it suitable for various industrial applications.

03Graphite Ore Beneficiation Process

BackThe general process for graphite ore beneficiation involves several stages, including ore crushing, grinding, flotation, and dewatering. Each stage is essential for the successful extraction and purification of the graphite.

1. Crushing and Grinding

The first step in the beneficiation process is the reduction of the graphite ore size through crushing and grinding. This process begins with primary crushing, where the ore is reduced to a size that can be easily handled by the subsequent equipment. Secondary crushing may follow to further reduce the particle size of the ore.

After crushing, the graphite ore is ground in a ball mill or rod mill to achieve the desired particle size. Grinding helps to liberate the graphite flakes from the surrounding gangue minerals, facilitating their subsequent separation in the flotation process.

2. Flotation

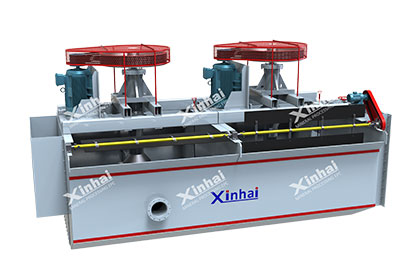

Flotation is a crucial stage in the beneficiation process, as it separates the valuable graphite flakes from the unwanted gangue minerals. This process involves the addition of reagents, such as collectors, frothers, and regulators, to create a hydrophobic surface on the graphite particles. The hydrophobic graphite particles then attach to air bubbles and float to the surface of the flotation cell, where they can be collected.

Several flotation techniques are employed to enhance the separation efficiency, including mechanical, column, and froth flotation. The choice of flotation method depends on factors such as the ore characteristics, reagent availability, and equipment requirements.

3. Concentrate Dewatering

After the flotation process, the graphite concentrate must be dewatered to reduce the moisture content. Dewatering is achieved through a combination of thickening and filtration.

The thickening process involves the separation of solids from the liquid phase by gravity settling. The concentrated slurry is then passed through a series of filters, such as vacuum or pressure filters, to remove excess water and achieve the desired moisture content.

4. Final Product Purification

The final stage in the beneficiation process is the purification of the graphite concentrate. Purification methods include chemical leaching, high-temperature treatment, and acid washing, which aim to remove impurities such as silica, iron, and other trace elements.

The choice of purification method depends on the specific impurities present in the concentrate and the required product specifications. The purified graphite is then dried, packaged, and shipped to customers for various applications.

04Conclusion

BackThe graphite ore beneficiation process is a vital step in the production of high-quality graphite for various industries. Through a series of carefully controlled stages, including crushing, grinding, flotation, and dewatering, the raw graphite ore is transformed into a valuable industrial resource with unique properties. As the demand for graphite continues to grow, advances in beneficiation technology will help to ensure that this critical material remains readily available for a wide range of applications.

You can also click to know the comprehensive guide to graphite processing equipment.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now