What's the Price of a Graphite Processing Plant?

shirley

shirley

Sep 26, 2023

Sep 26, 2023

1856

1856

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Graphite is a mineral primarily used in industrial applications due to its properties as a conductor of electricity. It's widely used in the manufacture of lithium-ion batteries, brake linings, steelmaking, lubricants, and pencils. To turn raw graphite into a usable product, it must be processed, and this is done in a graphite processing plant. Before we have talked about the 7 graphite processing methods. This article will delve into the various factors that affect the cost of a graphite processing plant and provide a rough cost estimate.

01 Size and Capacity of the Plant

BackThe first factor that significantly influences the price of a graphite processing plant is its size and capacity. A plant intended to produce large quantities of processed graphite for major industrial applications will naturally cost more than a smaller one designed for limited production. The capacity is usually measured in tons per year, and the price scales upwards with increased capacity.

02 Design and Technology

BackThe design and technology incorporated into the plant also have a substantial impact on the price. Advanced technology for better efficiency, automation, and environmental friendliness comes at a higher cost. The plant layout, whether it's a single-line configuration or multiple-line configuration, affects the overall cost.

03 Equipment and Machinery

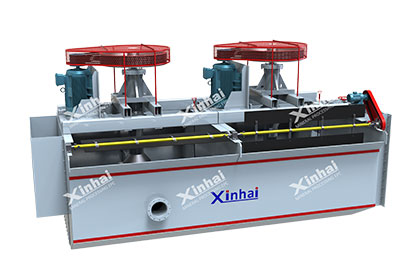

BackThe type and number of equipment and machinery required in the plant significantly contribute to the price. This includes crushing equipment, grinding equipment, flotation equipment, drying equipment, and dust collection equipment, among others. The cost of this equipment can vary widely based on its specific characteristics and the vendor.

04 Installation and Setup

BackThe cost of installing and setting up the plant is another significant factor. This includes the cost of site preparation, construction, equipment installation, and commissioning. These costs can also vary widely based on the location, local labor costs, and the complexity of the installation.

05 Operation and Maintenance Costs

BackWhile these are not upfront costs, they should be factored into the overall price of a graphite processing plant. These include the costs of electricity, water, labor, spare parts, and maintenance. The efficiency of the plant's design and the local cost of these resources will influence these costs.

06 Regulatory Compliance

BackGraphite processing plants must comply with various local, regional, and national regulations, including environmental, safety, and health regulations. The cost of such compliance, which may include measures to control emissions and ensure worker safety, can be substantial.

07Price Estimation

BackGiven the complexity of factors involved, it's challenging to give an accurate price without specific details. However, as a rough estimation, a small-scale graphite processing plant might cost from $1 million to $5 million. A medium-scale plant could cost between $10 million and $50 million, while a large-scale plant could cost more than $100 million.

These are very rough estimates and the actual cost can vary widely based on the specific circumstances. It's recommended to get a professional cost estimate from a company experienced in graphite processing plant construction.

08Conclusion

BackThe cost of a graphite processing plant can be substantial and depends on many factors. These include the size and capacity of the plant, the technology and design, the equipment and machinery used, the installation and setup costs, the operating and maintenance costs, and the cost of regulatory compliance. It's important to consider all these factors when planning for a graphite processing plant.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now