Introduction of Chrome Ore Washing Process and Equipment

Sheena

Sheena

Aug 26, 2024

Aug 26, 2024

867

867

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

South-Africa-3000tpd-chrome-washing-plant

Chrome ore, mainly refers to ores containing chromium elements, such as chromite (FeCr₂O₄), which has important applications in modern industry. The washing process of chromite ore is the process of separating the chromium components in the ore from the veins or other impurities, which involves a series of complex processes and equipment. This article will introduce the main process flow and common equipment of chrome ore washing in detail.

01Chrome ore washing process

BackThe process of chrome ore washing usually includes the following main steps:

1.1 Crushing

Crushing is the first step of the washing process, the main purpose is to crush the large ore into smaller particles. Commonly used crushing equipment includes jaw crusher and impact crusher. Jaw crusher is suitable for primary crushing, which can deal with larger ore pieces; while impact crusher is used for secondary crushing, which deals with smaller ore particles and further reduces the particle size.

1.2 Grinding

The crushed ore needs to go through grinding treatment to improve the separation efficiency of ore and veinstone. Ball mill is a commonly used grinding equipment, which grinds the ore into fine particles through the impact and grinding action of steel balls. The grinding process can also refine the ore particles and promote the separation of ore and veinstone.

1.3 Classification

After grinding, the ore slurry enters the grading equipment for grading, and the commonly used equipment includes spiral classifier and vibrating screen. The purpose of grading is to separate the particles in the slurry according to their sizes, so that the slurry suitable for further processing will enter the next step of gravity separation.

1.4 Gravity sorting

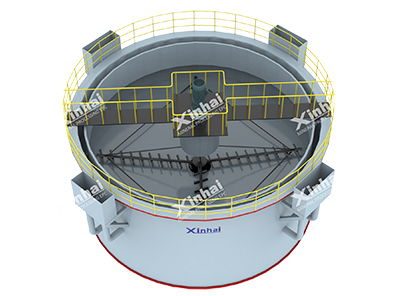

Gravity sorting is one of the most critical steps in chrome ore washing, separating chrome ore and veinstone by gravity difference. Common gravity separation equipment includes jigger, shaker and thickener. Jigger utilizes the difference in gravity generated by the slurry in the process of jumping, which makes the chrome ore particles sink while the veinstone floats. Shaking bed through the vibration on the bed surface, so that the slurry in the bed surface stratification, to achieve the purpose of sorting. The thickener is used to further increase the chromium content of the slurry and remove impurities.

1.5 Dewatering

The slurry after gravity separation contains more water, and needs to be dewatered. Commonly used dewatering equipment includes centrifuges and filters. The centrifuge separates the water in the slurry through high-speed rotation, and the filter removes the water through the filtration medium. The final chrome ore concentrate obtained can be further dried and treated.

1.6 Concentrate treatment and tailing treatment

The treated chrome ore concentrate usually requires further processing to improve its quality and purity. Tailings, on the other hand, need to be properly treated to minimize the impact on the environment, and common methods include tailings backfill, tailings stockpiling and tailings reprocessing.

02Common equipment and its characteristics

Back2.1 Jaw Crusher

Jaw crusher is a kind of equipment used for primary crushing of ores, and its working principle is to crush the ores through the alternating movement of two jaw plates. Its advantages are simple structure, easy operation, and suitable for handling larger pieces of ore.

2.2 Ball Mill

Ball mill is a kind of equipment that utilizes steel balls to grind ore. Through constant friction and impact, it grinds the ore particles finer. Ball mill is suitable for fine grinding and crushing of ores, and can improve the sorting effect of ores.

2.3 Spiral Classifier

Spiral classifier is a kind of equipment that utilizes spiral blades to classify, which separates the coarse particles and fine particles in the ore pulp through the rotation of spiral blades. Spiral classifier is suitable for the grading treatment of ore slurry, which can improve the grading precision of ore.

2.4 Jigger

Jigger is a kind of equipment that utilizes the gravity difference of the ore slurry in the beating process for sorting. It separates chrome ore particles and veins through vibration and gravity. Jigger has the advantages of high efficiency and simple operation.

2.5 Shaking bed

Shaking table is a kind of sorting equipment through the vibration on the bed surface. It realizes the separation of chrome ore and veinstone through the stratification of slurry on the bed surface. Shaking table is suitable for processing slurry with small particle size, which can improve the sorting precision of ore.

2.6 Centrifuge

Centrifuge separates the water in the slurry through the centrifugal force generated by high-speed rotation. It has the advantages of strong processing capacity and good dewatering effect, and is widely used in the dewatering treatment of ores.

03Summary

BackThe chrome ore washing process separates the chrome components from the chrome ore and the veinstone through the steps of crushing, grinding, classifying, gravity sorting and dewatering. The equipment in each step, such as jaw crusher, ball mill, spiral classifier, jigger, shaking table and centrifuge, plays a key role in ensuring the efficiency and effectiveness of chrome ore process. In actual operation, it is necessary to choose suitable equipment and process parameters according to the specific nature of the ore and washing requirements, in order to achieve the best washing effect.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now