Introduction of Gold Extraction Methods

Sheena

Sheena

Feb 26, 2025

Feb 26, 2025

209

209

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Today, we will introduce gold extraction methods. There are seven methods used for gold extraction, each suited for different types of ore and conditions. Here are some of the main methods:

01Gravity Separation

Backa. Process: This method relies on the difference in density between gold and other minerals. Gold, being heavier, can be separated from lighter minerals through various processes like panning, sluicing, or using a shaking table.

b. Usage: Commonly used in placer mining where gold is found in loose material such as sand or gravel.

02Cyanidation (Cyanide Leaching)

Backa. Process: Cyanide is used to dissolve gold from ore. The cyanide solution reacts with gold to form a soluble complex, which is then extracted from the ore. Afterward, gold is recovered from the solution using methods like activated carbon adsorption or electro-winning.

b. Usage: Most commonly used for gold extraction from low-grade ores or ore with fine gold particles.

c. Environmental Impact: Cyanide is toxic and poses a risk to the environment if not properly managed. But our ccompany have eco-friendly reagent.

.gif)

03Flotation

Backa. Process: This is a process in which finely ground ore is mixed with water, chemicals, and air to create a froth. Gold is attracted to the froth and can be separated from other materials.

b. Usage: Often used for ores containing sulfides or ores that do not respond well to gravity separation.

04Heap Leaching

Backa. Process: In heap leaching, gold ore is piled up in large heaps, and a leaching solution (often cyanide) is applied over the pile. The solution percolates through the heap, dissolving the gold, which is then collected at the bottom.

b. Usage: Used for low-grade ores, particularly in large-scale mining operations.

05Bioleaching

Backa. Process: Bioleaching uses bacteria to break down minerals and release gold from the ore. The bacteria feed on the minerals and produce acids that dissolve the gold.

b. Usage: A more environmentally friendly option compared to cyanidation, bioleaching is gaining popularity, particularly in situations where traditional methods are less effective.

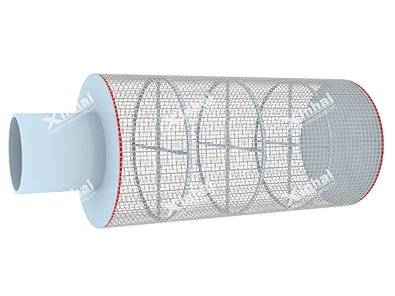

06Carbon in Pulp (CIP)

Backa. Process: In this method, the gold is dissolved in a cyanide solution and then adsorbed onto activated carbon. The gold-loaded carbon is then treated to recover the gold.

b. Usage: Widely used in large-scale gold mining operations.

07Carbon in Leach (CIL)

Backa. Process: Similar to CIP, but in this case, the carbon is added directly into the leaching tank during the process of cyanide extraction.

b. Usage: This method is used for higher-grade ores, as it allows for more efficient gold extraction.

Each method has its advantages and drawbacks, often influenced by the type of ore, environmental concerns, and cost. Let me know if you want more details on any specific method!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now