Introduction of Kaolin Extraction and Processing Equipment

Sheena

Sheena

Jan 18, 2025

Jan 18, 2025

269

269

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

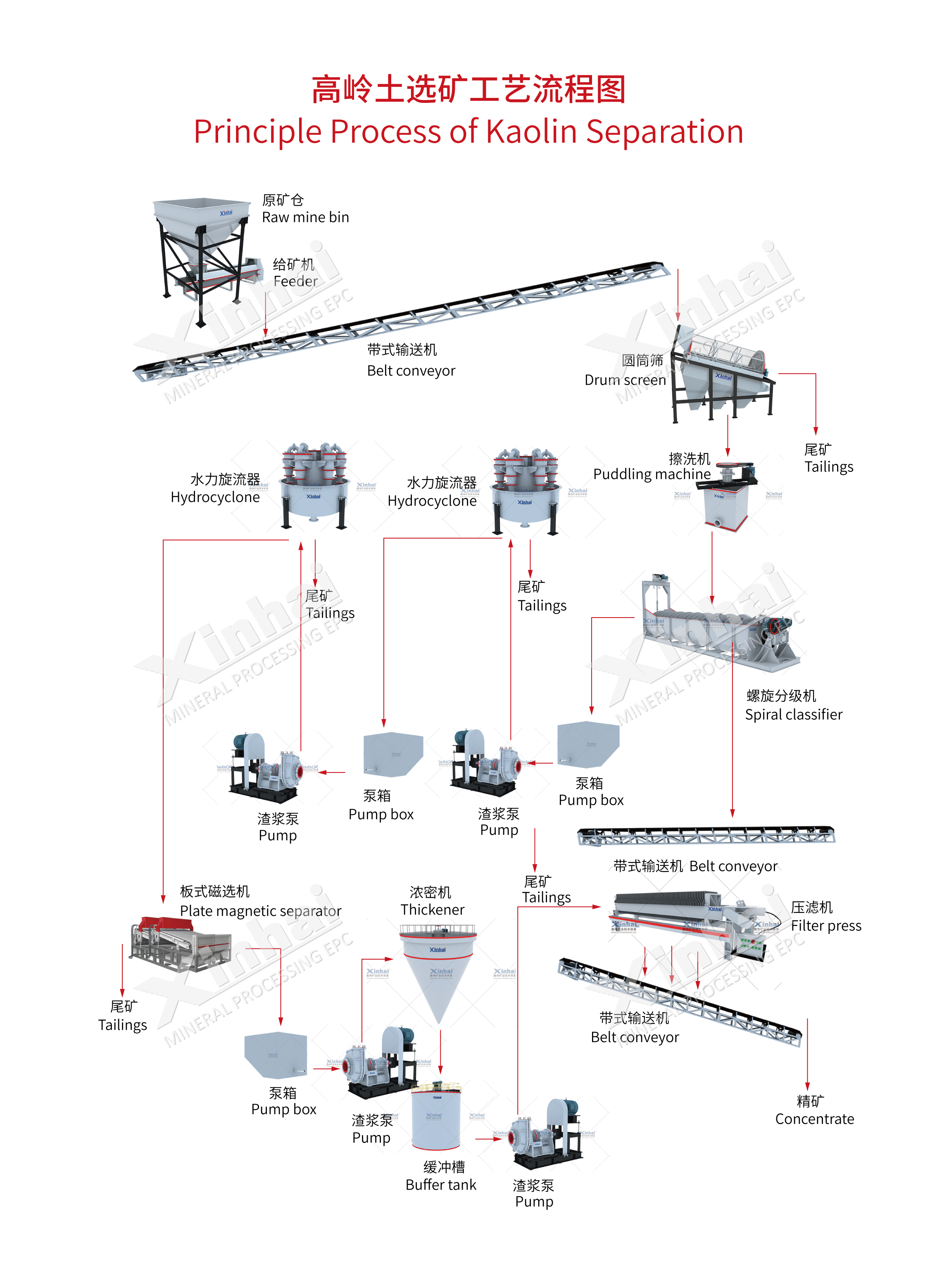

Kaolin-Classification-System

Kaolin extraction and processing require specialized technology and equipment to ensure the efficient and environmentally responsible recovery of kaolin clay. The specific technologies and equipment used depend on the type of kaolin deposit, desired product quality, and end-use applications. Below is an overview of the kaolin processing steps:

01Mining Technologies and Equipment

BackKaolin extraction typically involves open-pit mining, which is cost-effective and efficient for shallow deposits.

Key technologies and equipment include:

Excavators and Bulldozers: Used to remove the overburden (topsoil and rock) and expose the kaolin deposit.

Hydraulic Shovels: For precise extraction of the clay.

Dump Trucks: To transport raw kaolin ore to the processing facility.

Drilling and Blasting Equipment: Occasionally used if kaolin is embedded in harder rock formations.

02Beneficiation and Processing Technologies

BackA. Crushing and Grinding

The extracted ore is crushed into smaller pieces. It is then ground into a fine powder to facilitate further processing.

Jaw Crushers and Hammer Mills: For breaking large kaolin ore into smaller pieces.

Ball Mills: To grind kaolin into fine particles.

B. Washing and Slurrying

Water is added to the ground kaolin to create a slurry. This process helps to separate impurities and improves material flow for further refinement.

Agitation: Mix water with kaolin to create a slurry, improving flow and separating impurities.

Attrition Scrubbers: Enhance clay disaggregation and remove surface contaminants.

C. Screening and Classification

The slurry is screened to remove oversized particles and impurities.

Vibrating Screens: Remove oversized particles.

Hydrocyclones and Centrifuges: Classify particles based on size and density.

D. Beneficiation

This step involves removing impurities to improve the kaolin's purity.

Techniques include: magnetic separation, flotation and leaching.

Magnetic Separators: Remove iron oxides and other magnetic impurities, improving kaolin's whiteness.

Flotation Cells: Use chemical reagents to remove quartz, feldspar, and other unwanted minerals.

Leaching using chemicals to remove colored impurities.

03Dewatering and Drying Technologies

BackA. Filtration

Filter Presses and Vacuum Filters: Remove excess water from the kaolin slurry, forming a kaolin "cake."

B. Drying

Rotary Dryers: Heat and dry kaolin for reduced moisture content.

Spray Dryers: For fine and consistent particle sizes in dried kaolin.

04Environmental Technologies

BackKaolin extraction and processing facilities often use environmental control systems to minimize their ecological impact:

Water Recycling Systems: Reuse process water to reduce water consumption.

Dust Collectors: Prevent airborne particles during crushing and drying.

Waste Management Units: Properly dispose of or repurpose tailings and by-products.

If you'd like details on specific equipment models, setup layouts, or cost considerations, let me know!

+86 18234403483

+86 18234403483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now