Scheelite Ore Dressing Process and Prospects

Essow

Essow

Feb 27, 2024

Feb 27, 2024

752

752

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Scheelite, a significant source of tungsten, is a crucial mineral resource with widespread applications in military, aerospace, nuclear energy, electronics, and chemical industries. The beneficiation of scheelite ore is a complex process aimed at extracting high-purity tungsten concentrate from the ore.

(Scheelite Ore)

01 Scheelite Ore Dressing Process

Back1. Crushing

The initial stage of scheelite ore dressing is the reduction of large ore chunks into smaller, manageable pieces. This process is essential for increasing the surface area of the ore, which facilitates subsequent grinding and mineral liberation.

Primary Crushing: Large ore boulders are fed into primary crushers, such as jaw or gyratory crushers, which reduce the size to about 1-2 inches. The choice of crusher depends on the hardness and toughness of the ore.

Secondary Crushing: The output from the primary crusher is then fed into secondary crushers, such as cone or impact crushers, to further reduce the size to a few millimeters. This step ensures that the ore is sufficiently broken down for efficient grinding.

2. Grinding

Grinding is the process of reducing the ore particles to a size that allows for the separation of scheelite from the gangue minerals. This is typically achieved in mills that use grinding media, such as steel balls or rods, to grind the ore.

Ball Mills: The most common type of grinding mill, ball mills use a rotating drum filled with grinding media and ore. The ore is ground to a fine size, usually between 75 and 44 micrometers, which is optimal for the flotation process.

Rod Mills: These are less common in scheelite processing but can be used for coarser grinding. Rod mills use long cylindrical grinding media that provide a more even wear and can be more energy-efficient for certain ores.

3. Classification

Classification separates the ground ore into different size fractions, ensuring that only the particles fine enough for effective separation are passed to the next stage.

Spiral Classifiers: These devices use a spiral motion to separate particles by size, with finer particles being carried away in the water flow and coarser particles being discharged at the bottom.

Hydrocyclones: These are cone-shaped devices that use centrifugal force to separate particles based on their size and density. They are particularly effective for fine particle classification.

4. Beneficiation

The beneficiation stage is where the actual separation of scheelite from the gangue occurs. The primary methods used for scheelite ore are:

Gravity Separation: This method relies on the difference in density between scheelite and the gangue minerals. Techniques such as shaking tables, spiral concentrators, and centrifugal concentrators are used to separate the heavier scheelite from the lighter gangue.

Flotation: This is the most widely used method for scheelite ore. It involves the addition of chemical reagents to the ground ore pulp, which causes the scheelite particles to become hydrophobic and attach to air bubbles, allowing them to be floated to the surface. The flotation process requires careful control of pH, temperature, and the types and amounts of reagents used.

Collectors: These are chemicals that adsorb onto the surface of scheelite particles, making them hydrophobic.

Frother: This reagent helps to stabilize the air bubbles and increase the recovery of scheelite.

Modifiers: These can be used to adjust the selectivity of the flotation process, either by depressing the gangue minerals or by enhancing the flotation of scheelite.

Magnetic Separation: Although scheelite is not strongly magnetic, magnetic separation can be used as a pre-concentration step to remove strongly magnetic gangue minerals.

(Flotation Machines)

5. Dewatering

After the beneficiation process, the concentrate is typically a pulp with a high water content. Dewatering is necessary to reduce the moisture content and prepare the concentrate for further processing.

Thickening: This process uses thickeners or clarifiers to allow the solids to settle out of the pulp, resulting in a thicker, more concentrated product.

Filtration: Press filters or vacuum filters are used to remove the remaining water from the concentrate, producing a filter cake that can be further dried.

Drying: The filter cake is then dried using rotary dryers, fluid bed dryers, or other drying equipment to produce a dry concentrate.

6. Concentrate Treatment

The final stage of scheelite ore dressing involves the treatment of the concentrate to remove any remaining impurities and prepare it for smelting.

Roasting: This process involves heating the concentrate to oxidize any sulfide minerals and remove volatile impurities.

Acid Leaching: In some cases, the concentrate may be leached with acids to dissolve impurities, leaving behind a purer scheelite product.

Hydrometallurgical Processing: This involves the use of aqueous solutions to extract the tungsten from the concentrate, followed by purification and crystallization steps to produce high-purity tungsten compounds.

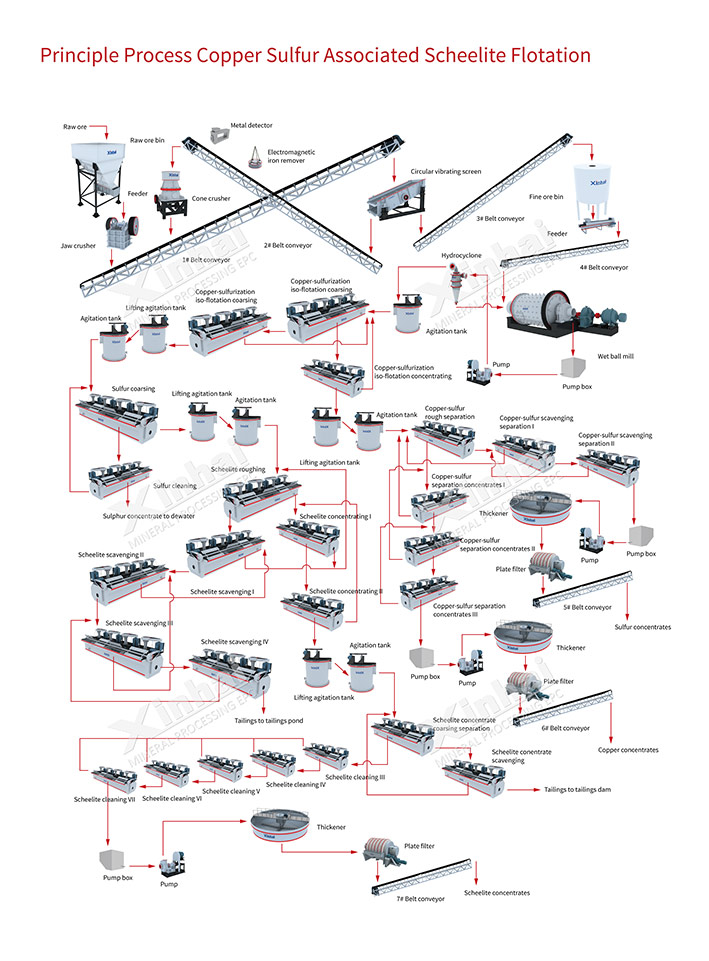

(Dressing Process Flowchart for Scheelite)

022. Optimization of the Dressing Process in Scheelite Ore Processing

BackOptimization of the dressing process in scheelite ore processing is a critical aspect of ensuring efficiency, cost-effectiveness, and environmental sustainability. It involves the fine-tuning of various operational parameters and the implementation of advanced technologies to enhance the recovery of scheelite and the quality of the final concentrate. Here's a more detailed look at the optimization strategies:

1. Ore Characterization and Testing

Before any optimization can take place, it's essential to have a thorough understanding of the ore's characteristics. This includes:

Mineralogy: Identifying the types and proportions of minerals present, including scheelite and gangue minerals.

Geochemistry: Analyzing the chemical composition of the ore, which can influence the choice of reagents and processing methods.

Particle Size Distribution: Understanding the size distribution of the ore particles, which affects grinding and classification efficiency.

Laboratory Testing: Conducting comprehensive laboratory tests, such as flotation tests, to determine the best conditions for each step of the process.

2. Process Control and Automation

Real-time Monitoring: Implementing sensors and control systems to monitor critical parameters like pH, temperature, and chemical concentrations in the process streams.

Automation: Using automated control systems to adjust these parameters in real-time, ensuring optimal conditions for each stage of the process.

3. Equipment Selection and Configuration

Crushing and Grinding Circuits: Choosing the right types of crushers and mills, and configuring them in a way that minimizes energy consumption and maximizes throughput.

Classifiers and Separators: Selecting classifiers that provide the best separation efficiency for the specific ore characteristics.

4. Reagent Optimization

Frothers and Collectors: Testing different reagents to find the most effective ones for the specific ore, and optimizing their dosages to improve recovery and reduce costs.

pH and Temperature Control: Adjusting the pH and temperature in the flotation circuit to enhance the selectivity and recovery of scheelite.

5. Tailings Management

Tailings Dam Design: Designing tailings dams to minimize environmental impact and ensure the safe containment of waste materials.

Recovery of Valuable Minerals: Exploring options for the recovery of other valuable minerals from the tailings, which can add to the overall profitability of the operation.

6. Energy Efficiency

Energy Audits: Regularly conducting energy audits to identify areas where energy consumption can be reduced.

Energy-saving Technologies: Implementing energy-saving technologies, such as variable speed drives for mills and pumps, and more efficient grinding media.

7. Environmental Considerations

Waste Reduction: Minimizing the generation of waste materials through process optimization and recycling.

Water Management: Implementing water recycling systems to reduce the consumption of fresh water and minimize the discharge of contaminated water.

8. Continuous Improvement

Benchmarking: Comparing performance against industry standards and best practices to identify areas for improvement.

Research and Development: Investing in R&D to explore new technologies and methods that can further enhance the dressing process.

9. Training and Skill Development

Operator Training: Providing ongoing training for plant operators to ensure they understand the importance of process control and can make informed decisions.

Skill Development: Encouraging a culture of continuous learning and skill development among all employees involved in the dressing process.

By focusing on these areas, a scheelite ore dressing operation can achieve a more efficient and sustainable process, leading to higher recovery rates, lower operating costs, and a smaller environmental footprint. It's important to remember that optimization is an ongoing process that requires regular review and adaptation to changing conditions and technological advancements.

03 Prospects of Scheelite Beneficiation Technology

BackFuture mining technologies for scheelite (white tungsten ore) are expected to focus on several key areas to improve efficiency, selectivity, and environmental sustainability.

1. X-ray Transmission (XRT) Technology for Pre-concentration

Studies have shown that low-content scheelite ore can be pre-concentrated using XRT technology before further processing. This method helps in reducing the amount of ore that needs to be processed, thereby saving energy and resources.

2. Mixed Collectors for Flotation

After pre-concentration, mixed collectors are applied to produce qualified scheelite concentrate. The use of mixed collectors can enhance the selectivity of scheelite over other minerals, leading to a higher-grade concentrate.

3. Inorganic Depressants

The application of inorganic depressants, such as sodium silicate and phosphates, is crucial for the separation of scheelite from calcium-bearing minerals. These depressants can effectively inhibit the flotation of unwanted minerals, improving the overall recovery of scheelite.

4. Organic Depressants

Research is ongoing to develop organic depressants that are non-toxic, easily degradable, and environmentally friendly. These depressants can offer an alternative to traditional inorganic depressants, which may cause environmental issues due to their extensive use.

5. Flotation Separation Depressants

A review of the literature indicates that researchers are exploring the use of various depressants, both inorganic and organic, to improve the flotation separation of scheelite from associated minerals. The study of their adsorption mechanisms and the optimization of their use are important areas of research.

6. Geochemical Characterization

The geochemistry of scheelite is being studied to understand the formation processes and the behavior of scheelite in different geological settings. This knowledge can help in developing more effective processing methods tailored to specific ore types.

7. Microtextural and Geochemical Approaches

Detailed studies of the microtextures and geochemical characteristics of scheelite can provide insights into the mineralization processes and help in optimizing the beneficiation strategies.

8. Sustainable Processing

With the increasing focus on sustainability, future technologies will likely emphasize the development of processes that minimize environmental impact, reduce waste, and promote the recycling of water and other resources.

04Conclusion

BackThe dressing of scheelite ore is a complex process involving multiple steps and technologies. By rationally selecting and optimizing dressing methods and processes, the recovery rate of tungsten and the quality of the concentrate can be effectively improved, providing high-quality raw materials for the smelting and application of tungsten. With the advancement of technology, new dressing technologies and equipment are emerging, which will further enhance the efficiency and environmental sustainability of scheelite ore dressing.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now