Step-by-Step Guide: Chrome Plant Process Flow Explained

Laura

Laura

Nov 26, 2023

Nov 26, 2023

6712

6712

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Aerial view of a mineral processing plant )

Chrome plants play a crucial role in the mining industry, as they are responsible for extracting and refining chromite ore, which is a valuable source of chromium. Chromium is an essential element used in various industries, including stainless steel production, chemical manufacturing, and metallurgy. Understanding the chrome plant process flow is essential for professionals and enthusiasts interested in the mining and extraction of this vital mineral.

In this comprehensive guide, we will take a step-by-step approach to explain the chrome plant process flow. We will delve into each stage of the process, exploring the equipment used, the chemical reactions involved, and the overall methodology employed. By the end of this guide, you will have a clear understanding of how a chrome plant operates and how chromite ore is transformed into high-quality chromium.

01 Exploration and Mine Development

BackThe chrome plant process flow begins with exploration and mine development. Geologists conduct surveys and studies to identify potential chrome ore deposits. Once a suitable site is identified, the mining process commences. This involves clearing the land, creating access roads, and establishing infrastructure to support mining operations.

02 Ore Extraction

BackThe next stage in the chrome plant process flow is ore extraction. There are several methods employed to extract chromite ore from the ground, including surface mining and underground mining. Surface mining involves the removal of soil and overburden to expose the ore, which is then extracted using heavy machinery, such as excavators and loaders. Underground mining, on the other hand, involves creating tunnels to access the ore deposits.

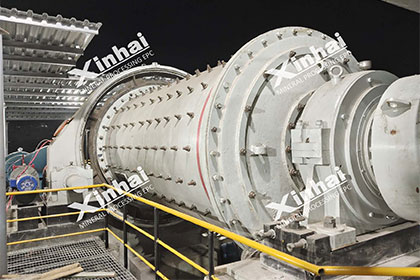

03 Crushing and Grinding

BackAfter the ore is extracted, it undergoes crushing and grinding to reduce its size and prepare it for further processing. The ore is crushed into smaller pieces using crushers and then ground into a fine powder using grinding mills. This process increases the surface area of the ore, facilitating chemical reactions in the subsequent steps.

( Chrome Plant Process Flow Explained - Crucher )

04 Beneficiation

BackBeneficiation is a crucial step in the chrome plant process flow, as it involves the separation of chromite from other minerals present in the ore. Various techniques, such as gravity separation, magnetic separation, and flotation, are used to achieve this separation. Gravity separation relies on the difference in density between chromite and other minerals, while magnetic separation uses magnetic properties to separate the ore. Flotation involves the use of chemicals to selectively separate chromite particles from the rest of the ore.

( Chrome Plant Process Flow Explained - Flotation machines )

05 Roasting and Leaching

BackOnce the chromite is separated from the impurities, it undergoes roasting and leaching. Roasting involves heating the chromite ore in the presence of air or oxygen to convert any remaining iron and sulfur compounds into oxides, which can be easily removed. Leaching is a process where the roasted ore is treated with a leaching agent, typically an acid, to dissolve chromium compounds. The resulting solution contains dissolved chromium, which can be further processed to obtain pure chromium.

06 Precipitation and Refining

BackThe next stage involves precipitation and refining of the chromium from the solution obtained in the leaching step. Precipitation is achieved by adjusting the pH of the solution, causing the chromium to precipitate as a solid. The solid chromium is then separated from the solution through filtration or other separation techniques. The obtained chromium is further refined to remove any impurities, ensuring the production of high-quality chromium.

07 Smelting and Alloying

BackIn some cases, the refined chromium is further processed through smelting and alloying. Smelting involves the fusion of chromium with other metals, such as iron or nickel, to produce alloys with specific properties. These alloys are widely used in the production of stainless steel and other applications requiring corrosion resistance, high strength, and heat resistance.

08 Final Product

BackAfter undergoing the smelting and alloying processes, the final product is obtained, which can be in the form of pure chromium, chromium alloys, or intermediate materials used in downstream industries. The final product is then packaged, ready for shipment to various manufacturers and industries that rely on chromium for their operations.

09Conclusion

BackUnderstanding the chrome plant process flow is essential for anyone interested in the mining and extraction of chromite ore. From exploration and mine development to the final product, each stage plays a crucial role in transforming the raw material into valuable chromium. The step-by-step guide provided in this article highlights the equipment, chemical reactions, and methodologies employed in each stage of the chrome plant process flow.

By grasping the intricacies of the chrome plant process flow, professionals and enthusiasts can gain a deeper appreciation for the complexity and importance of the mining industry. Moreover, this knowledge enables us to make more informed decisions regarding the sustainable extraction and utilization of chromium, a vital mineral that contributes to various sectors of the global economy.

Feel free to contact us and learn more about processing methods to extract chrome ore and get a personalized guidance on chrome plant operations! Or you can leave a message and we will reply to you soon.

+86 18234403483

+86 18234403483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now