Nickel Ore Beneficiation: the Secret to Improve Productivity

Sheena

Sheena

Sep 04, 2024

Sep 04, 2024

839

839

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

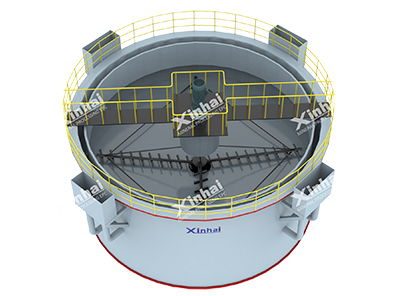

One of Xinhai nickel flotation plant

Nickel is an important non-ferrous metal, widely used in stainless steel, alloy materials, electronic batteries and many other fields. Beneficiation, the process of separating valuable minerals from unwanted impurities by physical or chemical methods, is a key step to improve the production efficiency of nickel ores. In this article, we will introduce the basics of nickel ore beneficiation and discuss the secret of improving production efficiency.

01The types and characteristics of nickel ore

BackNickel ore is mainly divided into two categories: nickel sulfide ore and nickel oxide ore (also known as nickel laterite ore).

Nickel sulfide ore is mainly distributed in Canada, Russia, Australia and other countries, the nickel in the ore is mainly in the form of nickel pyrite, nickel sphalerite and other minerals.

Nickel oxide ore is widely distributed in tropical and subtropical regions, such as Indonesia, the Philippines and other countries, the nickel in the ore is mainly in the form of magnesite, limonite and other forms.

These two kinds of nickel ore due to the differences in mineral composition and nature, its beneficiation method is also different. Nickel sulfide ores are usually processed by flotation, while nickel oxide ores are mostly smelted by fire smelting or wet smelting. Therefore, understanding the type and characteristics of the ore is the first step in developing the beneficiation program.

02Nickel ore beneficiation methods

Back2.1 Beneficiation method of nickel sulfide ore

The beneficiation of nickel sulfide ore mainly adopts flotation method. Flotation method is a kind of use of mineral surface physical and chemical properties of the differences in the mineral particles suspended in water, and through the bubble adsorption of valuable minerals, to achieve the process of mineral separation. The core of the flotation method lies in adjusting the chemicals and controlling the flotation process parameters to improve the selectivity and recovery of minerals.

In the flotation process, the ore is first crushed and ground to a suitable particle size. Then flotation chemicals, such as trapping agent and frothing agent, are added to the slurry, so that the surfaces of nickel minerals and veins show different wettability. Under the action of bubbles, nickel minerals attached to the bubbles float to the surface of the slurry to form a foam layer, and then the foam layer is collected by a bubble scraper, thus realizing the enrichment of nickel minerals.

2.2 Beneficiation method of nickel oxide ore

The beneficiation process of nickel oxide ore mainly includes pyrometallurgical smelting and hydrometallurgical smelting. Pyrometallurgical smelting is suitable for ores with high nickel grade, and the nickel metal is extracted directly from the ores through high temperature reduction. Wet smelting is applicable to low-grade oxidized nickel ores, and commonly used methods include high-pressure acid leaching, atmospheric pressure acid leaching and ammonia leaching.

03Tips of improving production efficiency

BackIn nickel ore beneficiation, improving productivity means recovering as much nickel metal as possible per unit time, while reducing energy consumption and costs. Here are some key strategies to improve the productivity of ore dressing:

3.1 Optimize ore crushing and grinding processes

Ore crushing and grinding is the first step in mineral processing and has a significant impact on beneficiation efficiency. By choosing the right crusher and grinding equipment and optimizing the crushing and grinding process, we can effectively reduce the over-crushing phenomenon of the ore, reduce energy consumption, and improve the efficiency of the subsequent beneficiation process.

3.2 Reasonable use of flotation chemicals

The selection and dosage of flotation chemicals directly affect the flotation effect. By optimizing the formulation and adding order of chemicals, the selectivity and recovery of minerals can be improved. For example, the use of new high-efficiency recovery agents and frothing agents can significantly improve the recovery of nickel minerals in flotation, and at the same time reduce the consumption of chemicals to reduce costs.

3.3 Improvement of flotation process parameters

Flotation process parameters such as slurry concentration, bubble size, stirring speed, etc. have an important influence on the flotation process. Finding the optimal combination of process parameters through laboratory tests and field tests can effectively improve the flotation efficiency. In addition, the use of automated control systems for real-time monitoring and adjustment of the flotation process can also significantly improve production efficiency.

3.4 Introduction of advanced mineral processing equipment

Modern beneficiation equipment, such as high-efficiency flotation machines, automated thickeners and dewatering equipment, can significantly improve the productivity and stability of the beneficiation process. These equipments usually have higher processing capacity and recovery rate, as well as easier operation and lower maintenance cost.

3.5 Strengthen the comprehensive utilization of the process

During the beneficiation process, many of the wastes actually contain some amount of valuable metals. Through the secondary recycling of beneficiation waste, the utilization rate of resources can be further improved. For example, through methods such as tailings re-election or tailings brick making, the waste is transformed into valuable by-products to maximize the use of resources.

04Conclusion

BackNickel ore beneficiation is a complex and delicate process, which requires the selection of appropriate beneficiation methods and processes according to the nature and characteristics of the ore. The productivity of nickel ore beneficiation can be effectively improved by those tips. With the progress of science and technology and the continuous innovation of beneficiation technology, the efficiency of nickel ore beneficiation will be further improved, providing strong support for the efficient development and utilization of nickel resources around the world.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now