What Is the Cost of a Tungsten Processing Plant? A Simple Guide

Laura

Laura

Apr 08, 2025

Apr 08, 2025

482

482

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Tungsten ore gravity seperation processing plant

Tungsten, often called the "metal of extremes," is prized for its incredible strength, high melting point, and resistance to wear. It’s essential for industries like aerospace, mining, and electronics. But transforming raw tungsten ore into usable products like tungsten carbide or pure metal requires specialized processing—and that comes with significant costs. Whether you’re an investor, engineer, or industry enthusiast, this guide breaks down the expenses involved in setting up a tungsten processing plant, from equipment and energy to regulations and market dynamics.

01 What Is a Tungsten Processing Plant?

BackA tungsten processing plant refines raw ore (typically wolframite or scheelite) into high-value products:

1). Tungsten carbide: Used in cutting tools, drill bits, and industrial machinery.

2). Pure tungsten metal: Essential for aerospace components and electronics.

3). Tungsten chemicals: Used in coatings, catalysts, and energy storage.

The process involves crushing, grinding, chemical treatments, and high-temperature refining to achieve the desired purity and form.

02 Key Factors That Influence the Cost

Back1. Ore Type and Processing Method

The type of tungsten ore determines the complexity and cost of processing:

1). Wolframite: Often processed using pyrometallurgical methods (high-temperature roasting), which are energy-intensive but efficient.

2). Scheelite: Typically treated with hydrometallurgical processes (chemical leaching), which require advanced technology and skilled labor.

Higher-grade ores reduce processing steps and costs, while low-grade ores demand more energy and chemicals. (More about tungsten beneficiation process)

tungsten ore

2. Plant Location

Where you build the plant significantly impacts expenses:

1). Proximity to mines: Reduces transportation costs for raw ore. For example, plants in China (the world’s largest tungsten producer) benefit from nearby mining operations.

2). Labor costs: Countries like Vietnam and Bolivia offer lower wages ($10–$20 per hour) compared to Europe or North America ($25–$50 per hour).

3). Infrastructure: Remote locations may require investments in roads, power grids, and water systems. A plant in Canada’s rugged terrain, for instance, could cost 15–20% more than one in a well-connected region.

3. Equipment and Technology

The machinery needed depends on the processing stage:

1). Crushing and grinding: Jaw crushers, ball mills, and classifiers cost $2 million to $10 million.

2). Chemical processing: Leaching tanks, solvent extraction units, and furnaces range from $5 million to $30 million.

3). Automation: Advanced control systems add $1 million to $5 million upfront but reduce labor costs long-term.

Small-scale plants (processing 50–100 tons daily) might cost $15 million to build, while large facilities (500+ tons daily) can exceed $50 million.

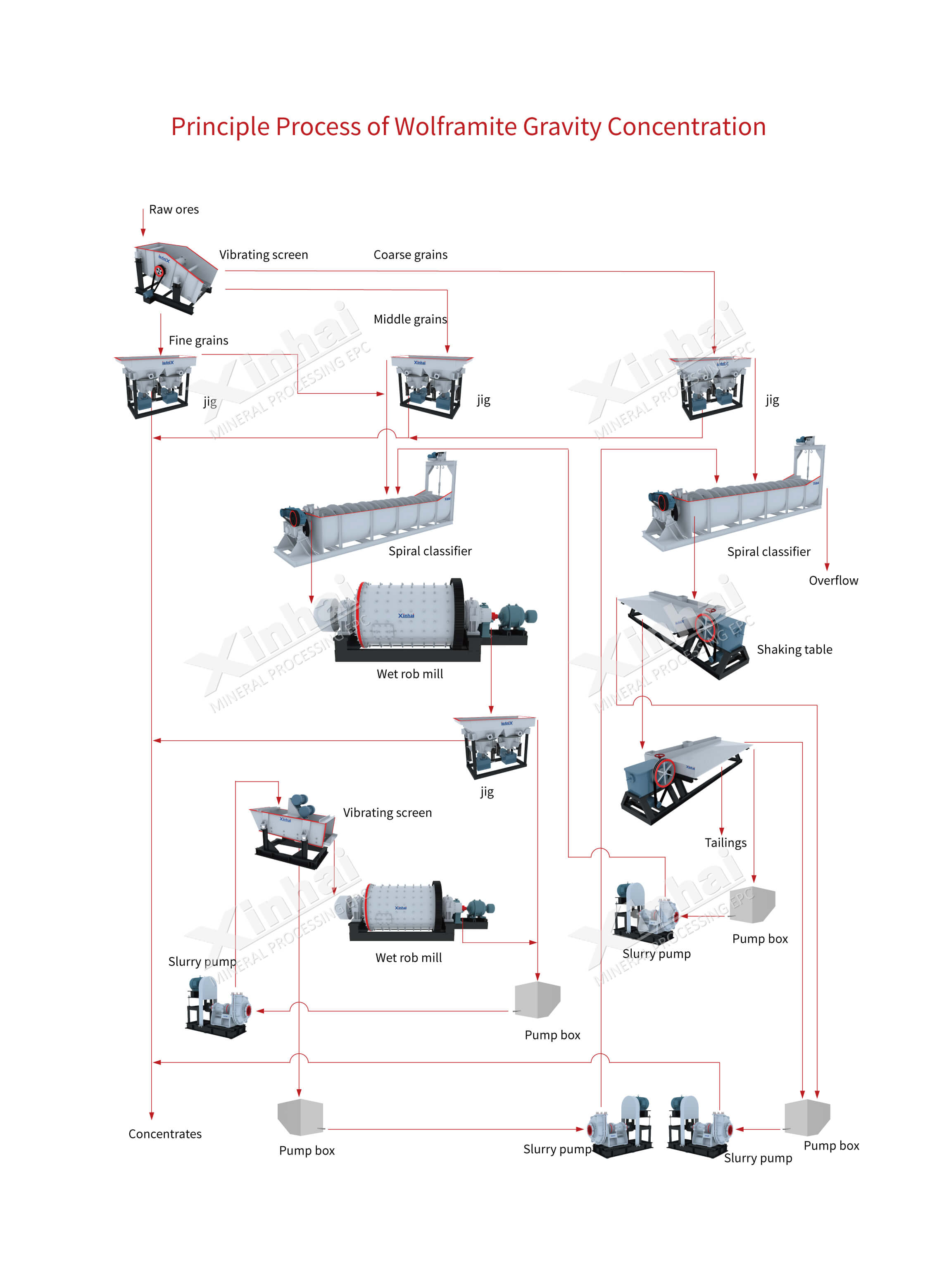

Tungsten-wolframite gravity separation process flow chat

4. Energy and Water Usage

Tungsten processing is energy-intensive, especially during high-temperature roasting and smelting. Energy costs can account for 30–50% of operational expenses. Some plants offset this by using renewable energy sources like hydropower, though initial setup costs are higher.

Water is critical for hydrometallurgical processes. Recycling systems, costing $1 million to $3 million, reduce consumption by up to 60% and help meet environmental standards.

5. Environmental and Regulatory Compliance

Strict environmental laws add to both startup and ongoing costs:

1). Waste management: Safely disposing of byproducts like arsenic and sulfur compounds can cost $2 million to $10 million.

2). Emissions control: Installing scrubbers and filters to reduce air pollution adds $1 million to $5 million.

3). Permitting: Securing licenses for water use, emissions, and land development can take 2–5 years and cost up to $2 million.

03 Breaking Down the Costs

Back1. Upfront Costs (CAPEX)

Building a tungsten processing plant requires significant initial investment:

Land acquisition: $1 million to $5 million, depending on location.

Equipment: $10 million to $40 million, varying with technology and scale.

Construction: $5 million to $20 million for buildings and infrastructure.

Permits and licenses: $500,000 to $2 million.

2. Ongoing Costs (OPEX)

Running the plant involves recurring expenses:

Labor: $2 million to $15 million annually, depending on automation and location.

Energy: $3 million to $20 million per year.

Maintenance: $1 million to $8 million for equipment repairs and upgrades.

Raw materials: $5 million to $25 million for tungsten ore.

Waste management: $1 million to $5 million.

A worker controls a shaking table to process tungsten ore

04 Market Trends and Profitability

Back1). Prices: Tungsten prices range from $30,000 to $50,000 per metric ton, depending on purity and market demand.

2). Demand: Growing use in aerospace, electric vehicles (EVs), and renewable energy systems is driving demand.

3). Supply: China controls 80% of global tungsten production, but new mines in Canada and Australia aim to diversify supply chains.

05 Risks and Challenges

Back1). Price volatility: Tungsten prices can swing due to geopolitical tensions or shifts in industrial demand.

2). Regulatory changes: Stricter environmental laws may require costly retrofits.

3). Competition: Recycled tungsten (from scrap tools and electronics) accounts for 30% of supply, offering a cheaper alternative.

06 FAQs

BackQ: How long does it take to build a tungsten processing plant?

A: Typically 3–5 years, including permitting, construction, and equipment installation.

Q: Can small-scale plants compete with large ones?

A: Yes, but they often focus on niche markets like tungsten chemicals or custom alloys.

Q: Is tungsten processing environmentally harmful?

A: Traditional methods have significant footprints, but modern plants use recycling and cleaner technologies to reduce impacts.

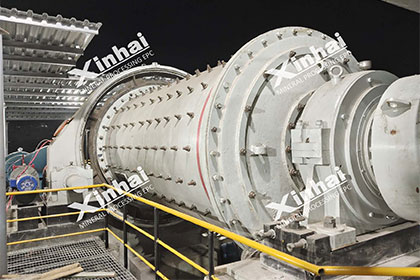

A ball mill for processing tungsten ore

07Conclusion

BackThe cost of a tungsten processing plant ranges from $15 million to over $50 million, influenced by ore type, location, technology, and regulations. While wolframite-focused plants may have lower energy costs, scheelite processing offers versatility for high-purity applications. Success hinges on strategic location, energy efficiency, and adapting to market trends. With tungsten’s critical role in high-tech industries, a well-planned plant could deliver strong returns—provided investors navigate price volatility and regulatory challenges.

Feel free to contact us and learn more about tungsten processing solutions. Or leave a message and we will reply to you soon!

+86 18234403483

+86 18234403483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now