Molybdenum Processing: Unlocking the Potential of a Valuable Resource

Essow

Essow

Mar 18, 2024

Mar 18, 2024

888

888

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Molybdenum, a versatile and valuable metal, has gained significant prominence in various industries due to its exceptional properties. Before it can be utilized in these industries, molybdenum undergoes a complex processing journey starting from the extraction of raw ore. In this article, we delve into the intricacies of molybdenum raw ore processing, exploring the methods and techniques involved in unlocking the potential of this valuable resource.

01 Molybdenum Ore Deposits and Mining

Back1. Ore Deposits

Molybdenum is primarily found in various ore deposits worldwide. The most common mineral containing molybdenum is molybdenite (MoS2), which typically occurs in hydrothermal veins associated with granitic rocks. Other minerals, such as wulfenite, powellite, and molybdite, also contain molybdenum, but they are less abundant.

2. Mining Techniques

The extraction of molybdenum-rich ore involves several mining techniques, depending on the nature and location of the deposit. Open-pit mining is commonly employed for shallow deposits, where the ore is accessed by removing overburden and extracting the ore using heavy machinery. Underground mining is utilized for deeper deposits, where tunnels are excavated to access the ore body.

02 Molybdenum Ore Processing

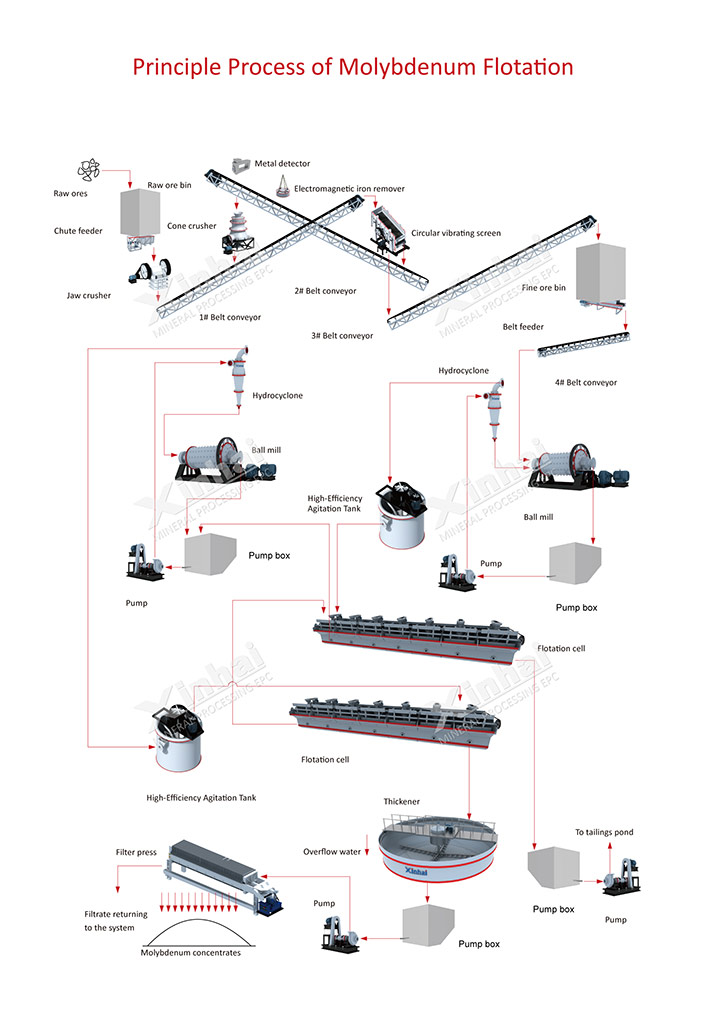

Back1. Crushing and Grinding

The raw molybdenum ore is first subjected to crushing and grinding processes to reduce the size of the ore particles. This step facilitates the liberation of molybdenite from the surrounding gangue minerals, allowing for efficient separation later in the processing chain.

Crushing and grinding are fundamental processes in the mineral processing industry that aim to reduce the size of the ore particles, enabling the liberation of valuable minerals from the surrounding gangue (unwanted minerals). Let's delve into these processes in more detail:

Crushing:

Crushing is the initial stage of ore processing, where large rocks and ore chunks are broken down into smaller fragments. The primary objective of crushing is to reduce the size of the ore particles to a level suitable for further processing. Different types of crushers are used depending on the nature of the ore and the desired product size.

Grinding:

Grinding is a subsequent step that further reduces the size of the crushed ore particles. It involves the use of grinding mills, which are rotating cylinders or drums containing grinding media such as steel balls or rods. The ore is fed into the mill, and as the mill rotates, the grinding media crush and grind the ore particles.

(Ball Mill)

2. Flotation

Flotation is the most widely used method for molybdenum ore processing. It relies on the differences in the surface properties of molybdenite and other minerals present in the ore. The crushed ore is mixed with water and various flotation reagents, including collectors, frothers, and modifiers. Air bubbles are then introduced into the mixture, causing the molybdenite particles to attach to the bubbles and rise to the surface as a froth. The froth is collected and further processed to obtain molybdenum concentrate.

Reagent Selection

Various reagents are used in molybdenum flotation to achieve selective separation. The choice of reagents depends on the specific ore characteristics and the desired molybdenum concentrate grade. Commonly used reagents in molybdenum flotation include collectors, frothers, depressants, and modifiers.

Collectors: Collectors are chemicals that selectively bind to the molybdenum minerals, making them hydrophobic and enabling their attachment to air bubbles. Xanthates, dithiophosphates, and mercaptobenzothiazole (MBT) are commonly used collectors for molybdenum flotation.

Frothers: Frothers are added to promote the formation and stability of mineral-laden froths, which carry the molybdenum minerals to the surface. Common frothers used in molybdenum flotation include pine oil and MIBC (methyl isobutyl carbinol).

Depressants: Depressants are reagents that selectively inhibit the flotation of certain minerals. In molybdenum flotation, depressants are often used to suppress copper minerals' flotation, allowing for selective recovery of molybdenum. Sodium hydrosulfide (NaHS) is commonly used as a copper depressant.

Modifiers: Modifiers are used to adjust the pH level and other properties of the flotation slurry to optimize molybdenum recovery. Lime (calcium oxide) or soda ash (sodium carbonate) is typically used as a pH modifier.

Flotation Process

The molybdenum flotation process follows the general principles of froth flotation. The conditioned ore slurry is introduced into a flotation cell, and reagents are added to promote selective attachment of molybdenum minerals to the air bubbles. The froth, containing molybdenum concentrate, is skimmed off and collected, while the remaining gangue minerals settle as tailings.

(Flotation Machines)

3. Thickening and Filtration

The molybdenum concentrate obtained from flotation is subjected to thickening and filtration processes to remove excess water and impurities. Thickening involves the removal of water from the concentrate by settling or centrifugation, while filtration further separates the solids from the remaining liquid.

4. Roasting

Roasting is a crucial step in molybdenum ore processing, which involves heating the concentrate in the presence of air or oxygen. The roasting process converts molybdenum sulfide (MoS2) into molybdenum trioxide (MoO3), which is a common intermediate product for further processing.

5. Chemical Conversion and Reduction

Chemical conversion techniques are employed to obtain various molybdenum compounds from molybdenum trioxide. For example, molybdenum trioxide can be converted into molybdenum dioxide (MoO2) or ammonium molybdate [(NH4)6Mo7O24·4H2O] depending on the desired application. Reduction processes are then used to produce metallic molybdenum from these compounds. Reduction can be achieved through hydrogen or carbon reduction at high temperatures.

Reduction processes are used to convert molybdenum compounds, such as molybdenum trioxide (MoO3) or molybdenum dioxide (MoO2), into metallic molybdenum. These reduction methods involve the removal of oxygen from the molybdenum compounds, resulting in the formation of pure molybdenum metal. Here are two commonly employed reduction processes:

Hydrogen Reduction:

Hydrogen reduction is a widely used method for producing metallic molybdenum. In this process, molybdenum compounds, typically molybdenum trioxide, are mixed with hydrogen gas (H2) and heated to high temperatures, usually between 700 to 1,200 degrees Celsius. The hydrogen gas acts as a reducing agent, reacting with the oxygen in the molybdenum compound to form water vapor (H2O) while leaving behind metallic molybdenum. The overall reaction can be represented as follows:

2 MoO3 + 3 H2 → 2 Mo + 3 H2O

The reaction is carried out in a controlled atmosphere to prevent oxidation of the molybdenum metal. The resulting metallic molybdenum is then collected, cooled, and further processed as needed.

Carbon Reduction:

Carbon reduction, also known as aluminothermic reduction, is another method employed for producing metallic molybdenum. In this process, molybdenum trioxide or molybdenum dioxide is mixed with a reducing agent, such as carbon or carbon monoxide (CO), and a reactive metal powder, typically aluminum. The mixture is ignited, initiating an exothermic reaction known as a thermite reaction. The heat generated by the reaction causes the reduction of molybdenum oxide, and the resulting molten metal collects at the bottom of the reaction vessel. The carbon reduction reaction can be represented as follows:

2 MoO3 + 3 C → 2 Mo + 3 CO2

The carbon monoxide produced in the reaction is typically removed by purging with an inert gas, such as argon, to prevent reoxidation of the molybdenum metal. The molten molybdenum is then cooled and solidified before further processing.

Both hydrogen reduction and carbon reduction are effective methods for producing metallic molybdenum. The choice of the reduction process depends on factors such as the starting molybdenum compound, the purity requirements of the final product, and the availability of resources. These reduction processes play a vital role in the overall molybdenum processing chain, enabling the production of high-quality molybdenum metal for various industrial applications.

(Molybdenum Processing Flowchart)

03 Refining and Further Processing

Back1. Refining

The molybdenum metal obtained from reduction processes may undergo additional refining steps to improve its purity. Refining techniques such as vacuum distillation, electron beam melting, and zone refining are employed to remove impurities and unwanted elements, ensuring the final molybdenum product meets the required specifications.

2. Alloying

Molybdenum's exceptional properties make it a sought-after alloying element. It is commonly used to enhance the strength, corrosion resistance, and high-temperature performance of various alloys. Molybdenum alloys find applications in the production of aircraft parts, electrical contacts, tool steels, and more. The alloying process involves melting molybdenum with other metals, such as iron, nickel, or titanium, to create the desired alloy composition.

3. Further Processing

Depending on the intended application, molybdenum can undergo various additional processing steps. These may include forming, machining, welding, or heat treatment processes to shape the material into the desired final product. These processes ensure that molybdenum is tailored to meet specific industry requirements.

04 Applications of Molybdenum

Back1. Aerospace and Automotive Industries

Molybdenum's exceptional properties, such as its high melting point, excellent strength, and thermal conductivity, make it an ideal material for aerospace and automotive applications. It is used in turbine engines, exhaust systems, and structural components, where its heat resistance and mechanical properties are crucial.

2. Electronics and Semiconductors

Molybdenum's low coefficient of thermal expansion and high electrical conductivity make it valuable in the electronics industry. It is used in the production of thin films for transistors, interconnects, and other electronic components. Molybdenum disulfide (MoS2) is also gaining attention as a potential material for next-generation semiconductor devices.

3. Energy and Renewable Technologies

Molybdenum finds applications in energy-related sectors, including oil and gas extraction, nuclear energy, and renewable technologies. It is used in catalysts, electrodes, and structural materials due to its ability to withstand harsh environments and improve energy efficiency.

4. Chemical and Catalyst Applications

Due to its excellent catalytic properties, molybdenum is used in various chemical processes. It plays a vital role in the production of chemicals, such as acetic acid and formaldehyde, as well as in the refining of petroleum products. Molybdenum catalysts are also employed in the desulfurization of fuels to reduce environmental pollution.

05Conclusion

BackMolybdenum raw ore processing plays a pivotal role in unlocking the potential of this valuable resource. From the extraction of raw ore to the various processing steps involved, such as crushing, grinding, flotation, roasting, and chemical conversion, each stage is crucial in obtaining molybdenum in its usable forms. Refining and further processing techniques further enhance the metal's purity and tailor it to meet specific industry requirements.

As molybdenum continues to prove its worth in industries such as aerospace, automotive, electronics, energy, and catalysis, the demand for this versatile metal is expected to grow. Researchers and engineers are continuously exploring innovative processing techniques to improve efficiency, sustainability, and the overall quality of molybdenum production.

By understanding the intricacies of molybdenum raw ore processing, we can harness the full potential of this valuable resource and continue to drive advancements in various industries, contributing to a more technologically advanced and sustainable future.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now