Dry Ball Mill VS Wet Ball Mill: What Are the Differences and How to Choose?

Star

Star

Nov 13, 2020

Nov 13, 2020

2918

2918

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

.jpg)

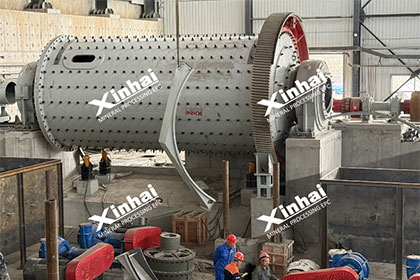

Ball mill is the key equipment for grinding materials after crushing. It is widely used in mining, construction, ceramics and glass industries. According to different grinding conditions, ball mills can be divided into dry ball mills and wet ball mills. The difference between the two is that one is grinding under dry conditions, and the other is grinding under wet conditions.

Besides, what is the difference between wet ball mill and dry ball mill and how to choose? This article will explain these two issues.

01Difference between wet grinding and dry grinding

Back1) Wet grinding

Wet grinding means that the material is ground with water (or absolute ethanol) in the ball mill, and when the grinding particle size meets the requirements, the material will be taken out by the water flow.

2) Dry grinding

Dry grinding means that the material is ground in the ball mill without water, and when the grinding particle size meets the requirements, the material will be taken out by the air flow drawn out of the cylinder.

02Wet ball mill VS dry ball mill

Back1) Structure

The shape and components of the wet ball mill and the dry ball mill are basically the same. The barrel is cylindrical, and the structure mainly includes the feeding part, the discharging part, the rotating part, the transmission part (reducer, small transmission gear, motor, electric control), etc.

Wet ball mill is relatively simple, without too many auxiliary accessories, the horn-shaped discharge port, and the built-in double-spiral discharge facility makes the discharge more convenient. The dry ball mill is more complicated, the discharge port is straight cylindrical, and is equipped with a draft device, a dust exhaust pipe and a dust collector.

2) Principle

The ball mill uses transmission machinery to drive the cylinder to rotate. The material is fed from the feed place. Under the action of centrifugal force, the steel ball, the material and the lining board in the cylinder collide, grind, peel, and friction, thereby completing the material grinding operation.

The wet ball mill needs to add water to reach the proper concentration when it is working. The qualified materials are discharged through the discharge part, and the unqualified materials are returned to the wet ball mill for regrind until the requirements are met.

When the dry ball mill is running, the material enters the hollow shaft from the feeding device, and the hollow shaft does a uniform spiral operation to send the material into the first warehouse. The warehouse is equipped with a step liner (or corrugated liner) and steel balls of different specifications. The grinding operation is completed by the collision between the material, the steel ball, and the liner.

3) Features

The wet ball mill has the following features: strong adaptability to materials, continuous production, large crushing ratio, easily fineness adjustment, high grinding efficiency, and low requirements for ore moisture content. In addition, the material transportation device is simple, so the investment is about 5%-10% lower than dry ball mills.

The dry ball mill adopts the forced discharge method of grate plate, it has the following features: smoother discharge, no higher ground phenomenon, cylinder no need cooled, smaller wear of the liner and the medium during fine grinding operation, long service life and low failure rate. However, due to the design of the barrel, the dry ball mill occasionally forms a dead angle, and the material is not easy to be sharpened in the dead angle.

4) Difference in applicable conditions

The wet ball mill has a wide range of applications and can be used to process various metal and non-metal minerals. Common minerals include: gold, silver, copper, iron, phosphorus, molybdenum, feldspar, fluorite, etc.

Dry ball mills can also be used for various metal ores and non-metallic ores grinding operations, but they are mostly used for materials that react with water, such as cement, marble and other building stones, or those that require storage and sales in powder form product.

03How to choose between the wet ball mill and the dry ball mill?

Back1) Wet ball mill is suitable for the following conditions:

Water will not affect the quality of the final product;

The ore that needs to be separated;

Fine particle size requirements;

Good investment environment, high extraction requirements.

2) Dry ball mill is suitable for the following conditions:

Materials that will react physically or chemically in contact with water;

Materials whose particle size requirements are not very fine;

Materials stored or sold in the form of grinding (such as glazes and pigments);

For some arid areas where water resources are relatively scarce.

04To Wrap Up

BackThe above briefly introduces the difference between wet ball mill and dry ball mill and the selection conditions. In fact, how to choose the ball mill correctly depends on the requirements of the subsequent operation of the ball mill or the working conditions. Only by identifying the grinding process used for the material can the correct grinding equipment be selected.

If you still have questions about the choice of wet ball mill or dry ball mill, or want to find more information about mill selection, you can submit a message or consult our online customer service, and we will contact you ASAP.

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Message

Message Chat Now

Chat Now