Guidance of Ball Mill Steel Balls

sharon

sharon

Nov 13, 2020

Nov 13, 2020

1203

1203

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

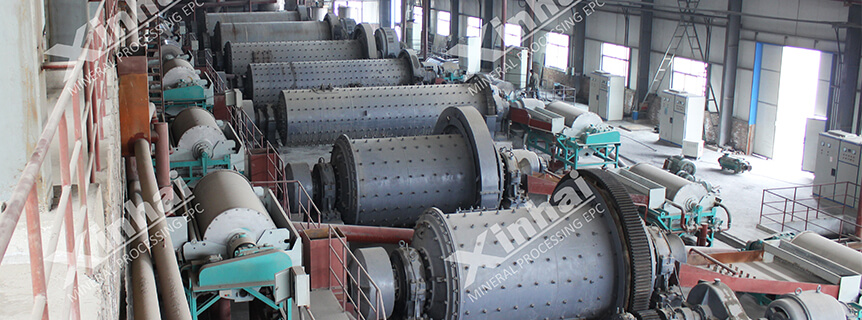

The steel ball is the medium for the ball mill to grind materials. The grinding effect is caused by the collision between the steel balls themselves and the collision friction between the steel balls and the material. The specifications, materials and usage of the steel balls will directly affect the work efficiency of the ball mill and even the entire production line of the concentrator, so it is valued by many mine owners.

We will introduce the ball mill steel balls in detail from the four aspects of the specifications, materials, proportions and gradations of the steel balls for the reference of all mine owners.

01 Specification of Ball Mill Steel Ball

BackIn general, the diameter of ball mill steel balls is between Φ20mm and Φ125mm, of which small steel balls are 40mm and 60mm, medium steel balls are 80mm, and large steel balls are 100mm or 120mm, etc. The diameter of super-large ball mill steel balls is mostly Φ130mm to Φ150mm.

02 Material of Ball Mill Steel Ball

BackAs a consumable in grinding process, the wear of steel balls varies with the difference of steel ball material. At present, the mainstream ball mill steel balls on the market mainly include cast steel balls and forged steel balls.

(1) Casting Steel Ball

Cast steel balls mainly include low chromium cast balls, medium chromium cast balls and high chromium cast balls. Its hardness, impact value and crushing rate are related to the metallographic structure of steel. The greater the chromium content of the steel ball, the better the wear resistance. To improve the wear resistance of the steel ball, it is necessary to increase its hardness, but as the hardness increases, the impact toughness of the steel ball will decrease. Therefore, to increase the hardness of the steel ball, the material and hardness of the liner must be taken into consideration.

(2) Forged Steel Ball

Forged steel balls mainly include low-carbon alloy steel balls, medium-carbon alloy steel balls, high-manganese steel balls, and rare earth chromium-molybdenum alloy steel balls, which have high impact toughness but low crushing rate.

Among them, the low-carbon alloy steel ball is made of low-carbon alloy, which has better toughness and low price. Under the same operating condition, its service life is more than twice that of low-chromium cast balls. High manganese steel has good toughness and low price. The main feature is that the surface layer will quickly produce work hardening under a larger impact. Its work hardening index is 5-7 times higher than other materials, and its wear resistance is greatly improved. High chromium cast iron is a kind of wear-resistant material with excellent abrasion resistance, but its toughness is low, so it is prone to brittle fracture and expensive.

03 Proportion of Ball Mill Steel Ball

BackSteel balls of different sizes in the bin have different proportions. For example, when the ball mill is used for the first time, three kinds of ball proportions of large, medium and small are required for proportioning, and when adding ball mill steel balls for the first time, the steel balls should be added according to 80% of the maximum ball capacity given by the manufacturer. After the installation of ball mill, the large and small gears of the ball mill need to be engaged. After the ball mill runs normally for two or three days, it is necessary to check the meshing of the large and small gears. If everything is normal, the operator can open the cover of ball mill inlet and add the remaining 20% steel balls for the second time.

In addition, small steel balls will usually be used when steel balls are added for the first time.

Because when the ball mill is running normally, the steel balls will produce reasonable friction, which will increase the abrasion, and both the large steel balls and the medium steel balls will become smaller. Therefore, there is no need to add small steel balls under normal circumstances. However, if the particle size is not implemented with a mineral monomer dissociation, and the fineness of the mill does not meet the separation requirements (especially the flotation separation requirements), an appropriate amount of small steel balls can be added.

In short, the steel balls of the ball mill are constantly worn during the operation. In order to maintain a reasonable filling rate and ratio of the steel balls to ensure the stable operation of the ball mill, the operators of the ball mill must make regular and reasonable ball replenishment with low compensation.

04 Gradation of Ball Mill Steel Balls

BackThe grading scheme for ball mill steel balls is usually determined from the first bin (i.e. coarse crushing bin). For multi-bin ball mill, the steel ball gradation of the first bin is particularly important. According to the principle of general cross-grading, i.e. the smallest ball diameter of the previous bin determines the largest ball diameter of the next bin, and so on, the ball grading of the first bin actually dominates the ball grading of the other bins.

At present, there are two common steel ball grading methods in the first bin of the ball mill: one is the multi-stage grading method, and the other is the two-stage grading method.

(1) Multi-Stage Grading Method

Multi-stage grading is a traditional steel ball grading method, usually 4-5 different types of ball mill steel balls are used for gradation. Specific steps are as follows:

The maximum ball diameter is determined by the maximum particle size of the material to be ground; the average ball diameter is determined according to the average particle size of the material to be ground.

To adjust the composition ratio of the steel balls of each specification according to the principle of the ratio of grinding media small at both ends and large in the middle and the characteristics of the material particle size distribution.

(2) Two-Stage Grading Method

The two-stage grading method refers to the grading of two types of ball mill steel balls with a large difference in diameter. The diameter of the big steel ball should be the same as the particle size of the grinding material, and the diameter of the small steel ball should be the same as the size of the gap between the big steel balls. Generally, the diameter of the small steel ball should be 13%-33% of the diameter of the large steel ball, and the small steel ball accounts for 3%-5% of the mass of the large steel ball. In principle, it should be ensured that the mixing amount of the small steel ball does not affect the large steel the filling rate of the ball.

05To Warp Up

BackThe above are the four main aspects involved in ball mill steel balls: specifications, materials, proportions and gradations of the steel balls. For concentrators, the selection and use of ball mill steel balls involves many technical issues. It is recommend that all mine owners carefully analyze the actual conditions and consult manufacturers with the overall qualification of mineral processing plant to select suitable ball mill steel balls. If you have other questions about the selection of the ball mill steel balls, you can consult the online customer service and leave a message, we will contact you as soon as possible!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now