How to Install and Debug Ball Mill Correctly?

xinhai

xinhai

Nov 02, 2020

Nov 02, 2020

4168

4168

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

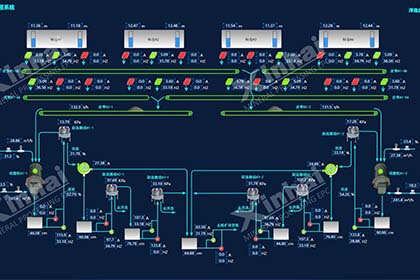

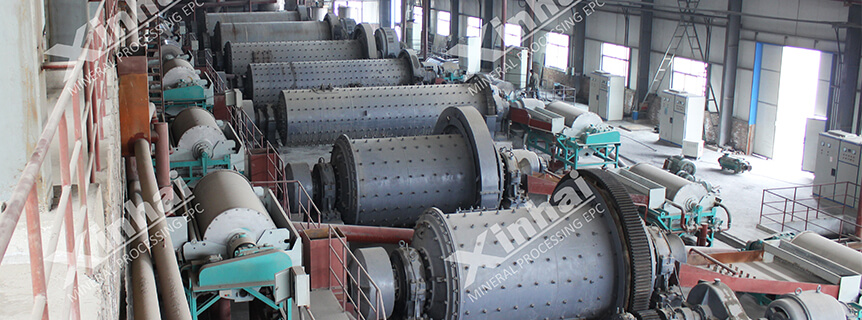

(Ball mill in iron processing plant)

A stable operation of ball mill plays an important role in the whole production line. In practice, there are many factors that affect the ball mill working efficiency, service life and use quality, but the key factor lies in correct installation and debugging of the ball mill itself. So this post will introduce how to install and debug ball correctly.

01 Ball Mill Structure and Working Principle

BackA complete ball mill is mainly composed of several parts, such as a feeding part, a discharge part, a transmission part, a main motor, a jacking device and an electric control box and so on.

At present, the common types of ball mills on the market are grid ball mills and overflow ball mills. The structures of these two types divide into two prats, working structure and transmission structure, whose main function is to grind materials by effective friction and centrifugal force.

Specifically, the cylinder shell of the ball mill is mainly made of steel plate rolled and welded. The flange on the cylinder and the hollow shafts at both ends of the feeding and discharging are connected as a whole with reamed hole bolts. There is a grinding body installed in the cylinder. The two ends of the cylinder are the inlet and outlet. The internal devices of the two hollow shafts, equipped with replaceable bushes inside, provide channels for feeding and discharging.

The cylinder of the mill moves around a horizontal axis, which generates a relatively high centrifugal force and brings mineral to a specified height by the action of the mixture, and then let it falls in a parabolic arc. In this process, the material will be impacted by the medium to a certain extent. Under the forces of crushing and collision, ball mill completes grinding process. Therefore, when ball mill is working, you feed new materials into the mill, and the material grounded and sent out under the help of water power, or wind power, etc.

02 How to Install Ball?

Back2.1 Installation Preparation

Generally, large-scale ball mill adopts rolling bearings, especially double-row spherical roller bearings which is generally with two rows of rollers and its function is to bear radial load and a certain axial load. So it is necessary to make some preparations for installing bearings.

Firstly, you have to make a related installation plan and organize the operation and management of equipment. Besides, relevant installers need to reconfirm the plan again to ensure the smooth progress of subsequent installation procedures. Then you should do the relevant verification work, carefully check whether the embedded bolts and the elevation are consistent with the design drawings. If the bolt hole has a large misalignment, you need to dismantle it and re-install this part.

Secondly, you have to bury the reference point and the corresponding central standard plate in accordance with the corresponding standard requirements. Before installation, you have to strengthen the cleaning of the equipment. For example, remove the anti-rust oil and dust on the equipment. In order to ensure a smooth installation process, you need to apply a layer of dry oil on the parts of the ball mill to make it keep a good lubrication performance. Especially for gradienter, level gauges, steel rulers and other magnetic bases, etc., you must apply some thin oil before use to ensure a certain degree of lubricity.

2.2 Installation Steps

There are different types of ball mills and their structures vary from each other, which requires the operator to install the specific ball mill scientifically in the corresponding order.

① Install the base of the ball mill

When installing the base of the ball mill, you need to prepare some shim with uneven thickness in advance, whose function is to adjust the position of the base. Under normal circumstances, if there is no looseness when side knocking the shim, it is considered qualified.

Before installing the base, you must analyze the base structure of the ball mill in detail to check whether it meets the relevant design requirements. You can observe whether the main bearing chassis of the ball mill is on the center line, and whether the coincidence degree exceeds 0.5 mm. It is necessary to check whether the feed end is higher than the discharge end by about 1mm. In addition, after the elevation bolts are tightened, you need to use theodolite to measure the chassis to see if it is on the same level as the chassis.

② Install the main bearing of the ball mill

You need to ensure that the journal and bearings of the ball mill can run and have good contact performance during the installation process. In addition, you must ensure that the two hollow shafts have the same degree of axiality, and control the center shaft and the bearing distance gap between 0.5mm and 1mm. You need to make the two sides of the free end have a certain degree of flexibility. Especially in some parts, due to the difference in temperature seasons, there are some differences in the hollow shaft shoulder and bearing gap. If the gap is set improperly, it will cause some bearing temperatures to be higher, and occur undesirable conditions such as bearing lockup at same time.

Therefore, when you install the ball mill in winter, the gap between the outer shoulder of the hollow shaft and the bearing should be smaller than the inner side. Compared to summer, the installation is just the opposite.

03 How to Debug the Ball Mill?

BackIn the process of debugging, first you need to turn the motor. Then you should let the motor run dry for 6 hours, and ensure that the voltage potential be within the designed range, and the bearing temperature fixed at 40°C. In addition, you need to run the load mill for 20 hours for debugging. If the ball mill runs smoothly without abnormal noise, and the tooth surface is in good contact, it indicates that the ball mill debugging work is relatively smooth and the equipment can operate normally.

In the commissioning, you need to make the bearing temperature less than 50°. At the same time, you should try to throw some materials to ensure that the ball mill works without any problems in the process of no-load operation. Then you can gradually add some materials until the ball mill reaches a higher load and runs over 48 hours. If each component runs smoothly without other abnormal vibration, the current value of the main motoris relatively stable and reaches the normal allowable range value. After 48 hours, you need to check the wear of the large and small gears. If the meshing is smooth and the bolts are not loosened, you can finish the commission.

04To Wrap Up

BackThe installation and commissioning of ball mill is an important task in the beneficiation plant, whose result will directly affect the quality of production and efficiency of the ball mill. It is recommended that you should choose a professional ball mill provider who can offer professional ball mill installation and commissioning personnel to help you make reasonable process parameters and get ball mill run normally.

If you have any question about ball mill installation and commissioning or some different ideas want to share with us, welcome to leave a message or consult online service.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now