6 Q&A You need to Know about Knelson Concentrator

Shirley

Shirley

Apr 08, 2021

Apr 08, 2021

6265

6265

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Knelson concentrator is an efficient centrifugal beneficiation equipment, named after its inventor Byron Knelson. This article will take you to further understand the knelson concentrator from the following 6 Q&A.

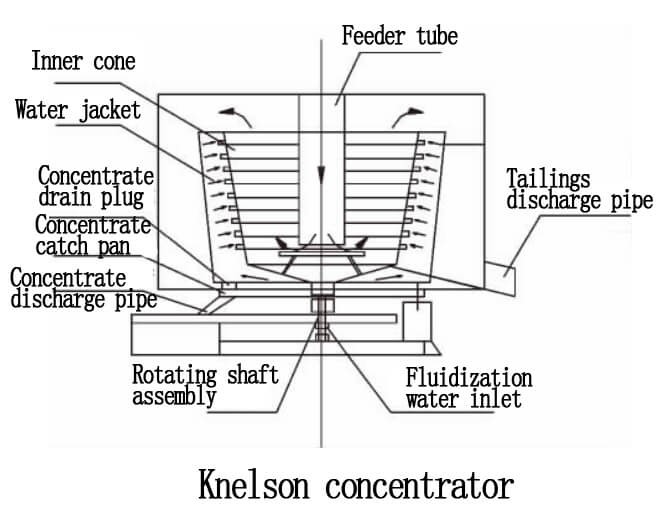

01 What's the Knelson Concentrator Structure?

BackThe separation mechanism of knelson concentrator is a double-walled cone with backwashing water holes on the inner wall, which can be understood as composed of two vertical concentric cones that can rotate together. The sealed water cavity is formed between the outer cone and the inner cone. The inner side of the inner cone has several circles of grooves and water inlet holes arranged according to a certain design. The rest of the Nielsen concentrator is composed of feeding, discharging, water(gas) supply devices and drives, automatic control systems and racks.

02 How does the Knelson Concentrator Work?

BackThe Nielsen concentrator is an enhanced gravity beneficiation equipment based on the principle of centrifugation. In the high intensification gravity field, the gravity difference between heavy and low specific gravity minerals is greatly magnified, making the separation between heavy and light minerals easier than in the natural gravity field. The specially designed material bed retention structure can continuously maintain a loose state under the interaction of patented fluidized water and interference settlement. Under the above conditions, heavy mineral particles can replace the position occupied by light mineral particles in the separation bed and remain, and light mineral particles are discharged as tailings, so that mineral particles can be sorted according to their specific gravity.

03 What are the Knelson Concentrator Types?

BackThere are two types of knelson concentrators, one is the discontinuous discharge type, and the other is the continuous variable discharge (CVD) type. According to the different yields of concentrates, the two types of products are suitable for different situations. Generally, the concentrate yield rate is 11% as the dividing line, and the discontinuous discharge type is considered below the dividing line. Otherwise, the continuous variable discharge type is used. The discharge cycle of the discontinuous discharge type knelson concentrator depends on the nature of the ore being processed, the amount of ore supplied, and so on. Vein ore generally takes 1 to 4 hours, and placer ore generally takes 4 to 12 hours. The continuously variable discharge type concentrator can discharge ore continuously, and continuously adjust the yield of concentrate according to the needs, which can be arbitrarily selected between 0-50%.

04 What's the Knelson Concentrator Used for?

BackKnelson centrifugal concentrator is mainly suitable for the recovery of precious metals such as gold, silver and platinum group, and is commonly used in gold flotation plants, CIP/CIL plants and gold gravity plants. The recovery rate can be increased by 2%-6% by adding the knelson concentrator to the flotation plant, and the carbon in pulp/leaching plant usually increases by 1%-3%. When the knelson concentrator is used in the gravity separation plant, the total gold recovery rate can reach 70-94%.

A gold mine in Australia processed 1.2 million t/a of ore, using carbon in leaching method. Coarse-grained gold was recovered by shaking table in the cyclone underflow in the original design of grinding circuit, and the recovery rate of gravity separation gold was only 31.22% after putting into operation. Then two 30-inch knelson concentrators were used to replace the shaker, the recovery rate increased from 31.22% to 32.18%, and the recovery rate of the whole gold plant increased by 2%. After using the knelson concentrator, the labor force is reduced, the working conditions are improved, and the economic benefits are increased.

05 What are the Knelson Concentrator Characteristics?

BackKnelson concentrator mainly has the following 6 characteristics:

High concentration ratio, usually 1000-3000 times. Concentrate grade is higher, generally 1000-2000g /t. The recovery rate is significantly higher than that of conventional gravity separation equipment.

Large processing capacity. The processing capacity of KC-XD70 and KC-CVD64 knelson concentrator can reach 300-1000T /h and 100-300T /h respectively.

Environmentally friendly. There is no need to add any chemicals during the operation of the knelson concentrator.

High operation rate, low power consumption, easy operation and management. Few operators, high automation degree, low daily maintenance, and low production cost.

Small floor space. The knelson concentrator is easy to integrate into the grinding circuit configuration in the reconstruction, expansion and new plant. It can be set at the tailings discharge point of the dressing plant to recover sulfide, iron, tin, tungsten, niobium, gold, silver, monazite, rutile and other metals or minerals with a particle size greater than 0.02mm.

Short separation process. The investment of knelson concentrator is less, and the return time is short, generally from 1 month to 1 year.

06 What's the Knelson Concentrator Price?

BackThe price of knelson concentrator is affected by many factors, such as types, capacity, motor power, etc. The general price of knelson concentrator is between $3,000-60,000. If you want to know the specific price, you can contact the online customer service of the website, we will tailor the appropriate equipment for your plant.

07To Wrap Up

BackThe above introduces the knelson concentrator from the six aspects of structure, working principle, category, application, characteristics and price. At present, the application of knelson concentrator has shown a good development trend, and has achieved good industrial results in Canada, Russia, Australia and Africa. With the continuous improvement and perfection of the equipment, the application of knelson concentrator will become more and more extensive.

If you want to know more information, please contact our online customer service or leave a message, we will contact you as soon as possible.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now