How to Select Slurry Pump?

Shirley

Shirley

Nov 13, 2020

Nov 13, 2020

4203

4203

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

In this post, we are going to talk about how to select slurry pump. Let’s dive in.

01 Pump Type

BackThere are many types of centrifugal slurry pumps. When you choose a slurry pump, you should choose suitable types according to the nature of the slurry. L-type pumps are suitable for low-abrasive slurry with a weight concentration of less than 30%; SP (SPR) pumps can work under the liquid that liquid level changes greatly; ZGB pump apply to the high-lift transportation.

02 Performance Parameter

BackAfter choosing the pump type, you need to determine the head and flow rate which is the basis for selecting the pump size. For conveying high-concentration and strong abrasive slurry, the rotation speed is generally about 3/4nmax. However, when the rotation number is 3/4 nmax, the flow rate is appropriate, but the head does not meet the requirements. At this time, you can use multiple pumps in series. Different slurries have a limited flow range:

For processing high-concentration and strong-abrasive slurry, the flow rate should be within the range of 40-80% of the pump's highest efficiency; for low-concentration abrasive slurry, the flow rate should be within the range of 40%-100% of the pump's highest efficiency.

03 Head

BackDue to the wear of the flow parts, the performance of the pump will decline, until it cannot meet the industrial requirements. In order to enable the pump to operate for a long time near the rated working conditions, you need to add a head margin when you select pump types. Generally, the margin is 10% of the rated head.

04 Materials of Over-Current Components

BackThere are many materials available for the over-current components of the slurry pump, which should be determined according to the physical (particle composition, particle size, shape, hardness, concentration) and chemical (acid, alkali, oil) characteristics of the conveying slurry.

05 Shaft Seal Type

BackThere are three main types of shaft seals for slurry pumps: packing seal, auxiliary impeller seal and mechanical seal.

The auxiliary impeller seal is generally used under reverse irrigation. The upper pipe pressure should be less than 10% of the pump outlet pressure. This type of shaft seal does not add shaft seal water, but this seal will increase power consumption, generally about 5% of the rated power .

The packing seal needs to add shaft seal water, and ensure sufficient water pressure and water volume. The shaft seal water pressure is equal to the pump outlet pressure plus 35Kpa.

The mechanical seal needs to add shaft sealing water, with good sealing performance and no leakage.

06 Transmission Mode

BackThe transmission mode of the slurry pump includes V-belt transmission, elastic coupling transmission, gear reduction box transmission, hydraulic coupling transmission, variable frequency driving device, and thyristor speed regulation. You can choose elastic coupling and V-belt, which are cheap and easy to disassemble. However the V-belt will increase the power consumption by 5%.

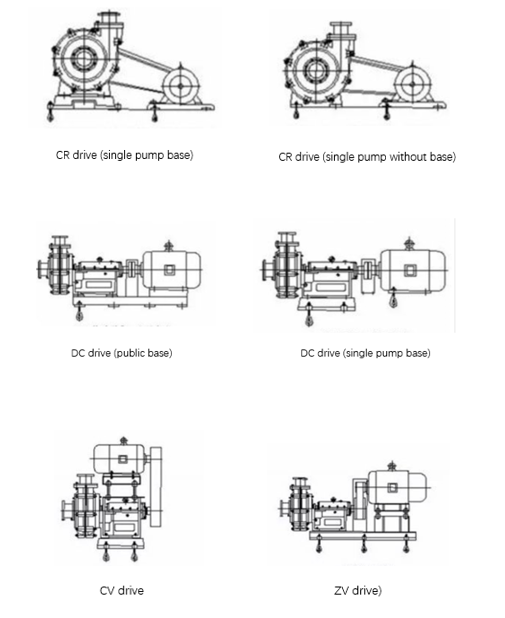

07 Installation Type

BackThere are many types of installation of slurry pumps,such as CV drive, DCZ drive, CRZ drive and ZVZ drive.

08 Complete Motor

BackConsidering factors such as pump startup and flow fluctuations, it is necessary to select a standard motor with a certain power richness factor. Generally, the rich system is 1.1-1.2, the high power is the small value, and the low power is the large value.

09To Wrap Up

BackThe above are 8 aspects you need to notice when choosing a slurry pump. A suitable slurry pump can not only ensure higher treatment efficiency, but also increase the service life of the slurry pump. In practice, you need to determine the appropriate slurry pump model according to the nature of the conveying material and the requirements of all aspects of the factory.

If you have any question about slurry pump or want to purchase it, welcome to contact our online customer service or leave a message, we will help you choose the truly suitable slurry pump model.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now