3 Common Problems and Solutions of Mining Thickeners

Shirley

Shirley

Apr 25, 2021

Apr 25, 2021

4832

4832

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

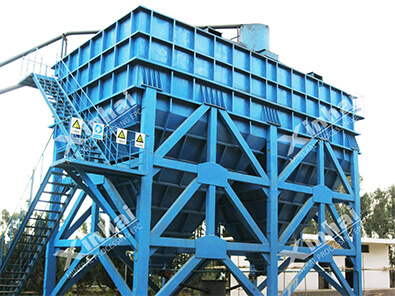

Thickener is a solid-liquid separation equipment based on gravity sedimentation, which is the commonly used thickening equipment in beneficiation plants. In actual production, most mineral processing plants will encounter various thickener problems, which will not only affect the normal operation of mineral beneficiation, but also seriously damage the economic benefits of mineral processing plants. This article will take you to know the three common problems of thickener, the causes and the corresponding solutions.

01 Overflowing Turbidity

BackOverflowing turbidity is one of the common failures of thickeners. The reasons and solutions for this problem are as follows.

Reasons

(1) The nature of the slurry into the tank causes turbidity after grinding and classifying. There is a certain amount of air mixed in the slurry, and the air causes a large number of bubbles to be generated during the mixing and stratification of the slurry, which makes it turbidity. If the slurry contains too much slime (especially fine slime of 0.1-0.001μm), it is difficult to clear the overflow, which can also cause turbidity.

(2) If the processing capacity is too large, the strong turning over of the slurry in the tank will also easily cause turbidity. Or the underflow control is too small, causing turbidity.

(3) Turbidity running caused by improper regulation of settling layer. The underflow discharge is large, and the sedimentation layer is too thin, so that some fine ore particles enter the overflow due to poor filtering effect. On the contrary, if the sedimentation layer is too thick, most of the water entering the pool will be blocked under the sedimentation layer, and the position of the sedimentation layer will float up.

Solutions

(1) Eliminate the unfavorable factors in the slurry. The air contained in the slurry can be eliminated by the welding frame degassing tank before entering the tank. For the 0.1-0.001μm fine sludge, the influence can be eliminated by adding electrolyte polymer flocculant or colloidal surface active material. Lime and flocculant can be added in the production to eliminate flocs and dense agglomerates formed by particle charge.

(2) The processing capacity of thickener should match with the process production capacity. The processing capacity of the thickener should refer to the related parameters of the cyclone, because the overflow amount of the cyclone is the ore supply capacity of the thickener. In addition, the thick underflow in production should not be adjusted too small, so as to avoid ore accumulation and turbidity, causing the rake to “sitting dead .

(3) Adjusting the sedimentation layer to maintain the thickness of 200~300mm. When the layer is thin, the bottom flow discharge should be reduced, otherwise it should be increased.

02 Improper Parameter Control

BackIn operation, the thickener should ensure the coordination of various parameters. The reasons and solutions for improper parameter control are as follows.

Reasons

(1) Improper lifting of the rake. If the rake frame is not raised after a sudden power failure, and the motor is directly started when the power is turned on, the worm gear may be damaged, which is caused by the rake frame sitting dead.

(2) Inapproper concentration ratio. Improper concentration ratio is mainly manifested in obvious deviation of concentration ratio from technical standard. The reason for the lower ratio may be that the concentration in the pool is too thin, or the concentration is sticky after concentration, which blocks the bottom flow discharge pipe valve. The reason for the higher ratio may be that the dense ore supply concentration is too large, or the ore discharge concentration is too small.

(3) No observation hole on the side wall of thickener. Since there is no observation hole, the thickness of the clarification layer and the filter sedimentation layer in the pool cannot be directly observed, and can only be judged by experience. As a result, it brings a lot of inconvenience to the operation and control, which leads to the disordered stratification in the pool and the increase of the probability of muddy overflow.

Solutions

(1) Timely lifting rake frame, adjust the speed. If there is a sudden power failure, it is necessary to manually reverse rotation rake to make it rise, and down it again when the power comes.

(2) Adjust the concentration ratio to 2.0-2.3 to make it meet the technical standards. Concentration ratio is an efficiency index to check the precipitation difficulty of pulp in a certain period of time. Most of the thick washing comes from the cyclone supply. The concentration before concentration is also the overflow concentration of the cyclone. The required standard is 20%, and the product concentration after concentration is 40%~45%.

(3) Setting observation hole on the side wall of the thickener to adjust the thickness of the clarification layer and the filter sedimentation layer to the standard range of 250-550mm.

03 Uneven Addition of Flocculant

BackDuring the concentration process, the uneven addition of flocculant will affect the settling efficiency. The causes and solutions are as follows.

Reasons

(1) Wrong dosing method. When the flocculant is added to the stirring tank, first add the reagent and then water, or add it at the same time as the water, or pour the medicine into the tank at one time, will make the mixing liquid uneven. Sometimes flocculated insoluble matter can be clearly seen in the tank, which is not conducive to concentration and precipitation.

(2) Long dissolution time of the flocculant. After stirring and dissolving, if it is not fully dissolved after 8 hours, the production will be affected.

Solutions

(1) Add flocculant correctly. When the tank is filled with water to the blades, shake the sieve and slowly sprinkle in the flocculant until the addition is complete. Avoid flocculant moisture or flocculation before adding. Do not pour the flocculant at one time to prevent the tank from overflowing due to excessive liquid injection.

(2) Shorten the dissolution time of flocculant. Increasing the rotating speed of the agitation tank is beneficial to the uniform diffusion of the flocculant.

04To Wrap Up

BackThe above introduce three common problems of thickener, the causes and the corresponding solutions. When the thickener fails, the staff must carefully analyze the cause, and must not operate blindly. In the actual production, each mine owner should pay attention to the daily maintenance and overhaul of the thickener to ensure the smooth operation of the whole mineral processing plant.

If you want to know more info, you can consult with the online service or submite a message, we will contact with you soon.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now