The Features and Differences between Jaw Crusher and Gyratory Crusher

Laura

Laura

Sep 02, 2021

Sep 02, 2021

2269

2269

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

(A jaw crusher and a cone crusher from Xinhai are at work in Russia's 500tpd gold ore dressing plant)

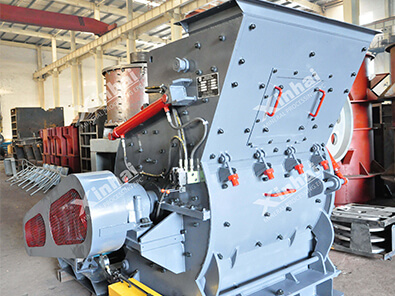

There are many types of crushers in mining, mainly jaw crushers, gyratory crushers, impact crushers, cone crushers, hammer crushers and roller crushers. In this article, we will introduce and compare jaw crushers and gyratory crushers.

01 Jaw Crusher

Back1) Working Principle

The crushing work of the jaw crusher is carried out by two crushing surfaces, which are crushed by the rapid collision of the intelligible tooth plates. The ore enters the crushing cavity from the upper feeding port. When the movable tooth plate advances forward, the ore is crushed. When the tooth plate moves backward, the ore moves upward and downward, and is discharged to the lower part after several collisions.

2) Features

a. The structure is simple, the worn parts and the liner are easy to replace, and it is easy to take care of and repair

b. The force on the upper part of the movable tooth plate increases with the proximity to the fixed tooth plate. The greater the obtuse angle formed by the thrust plate, the greater the force. The maximum force formed on the upper part of the movable tooth plate causes larger pieces of ore to be crushed first, and it is quite effective to crush hard raw ore.

c. Vibration is large during work and should be installed on a fixed and solid foundation

d. It is required to feed the ore with a uniform particle size, otherwise the crusher is easy to be blocked, and the miner must be set before crushing

e. It is suitable for crushing massive ore, and sometimes the discharge particle size is too large for strip or flake ore.

(A jaw crusher works in Morocco's 500tpd silver ore dressing plant)

02 Gyratory Crusher

Back1) Working Principle

Two interface cones form a crushing cavity that gets smaller downwards. The shell is called a fixed cone. The moving cone is suspended on a beam over the top of the fixed cone. When the crusher moves downward, it is eccentric. When the shaft sleeve rotates, the moving cone and the conical surface are eccentrically rotated to crush the ore.

2) Features

a. Due to the large body shape of the gyratory crusher, the corresponding processing capacity will also be large

b. Compared with the jaw crusher, the energy consumption of the gyratory crusher is lower

03 Compare of Jaw Crusher and Gyratory Crusher

BackBelow we use the table to compare the characteristics of the jaw crusher and the gyratory crusher.

Item | Jaw Crusher | Gyratory Crusher |

Body shape of crusher | Small | Big |

Weight of crusher | Light | Heavy |

Maintenance | Convenient | Difficult |

Construction investment | Little | Much |

Power consumption per ton of ore | Much | Little |

The feeding conditions | Feeding machines needed | Feeding machines no needed |

Particle size of product | Uneven | Even |

Crushing effect of flake and strip ore | Bad | Good |

Vibration performance | Strong | Common |

Crusher scale | Small | Big |

04To Wrap Up

BackIn this article, we mainly introduced the jaw crusher and the gyratory crusher from the working principle and characteristics, and we also briefly explained the difference between the two crushers in the form of a table. When we choose the crushing equipment, we must comprehensively consider the production capacity of the mine, the nature of the ore, the size of the original ore and the required product size. In the next article, we will focus on other types of crushers.

At last, you can click on this link to learn more about crushers.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now