What is Mobile Crushing Station in Mining?

Laura

Laura

Aug 31, 2021

Aug 31, 2021

1446

1446

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

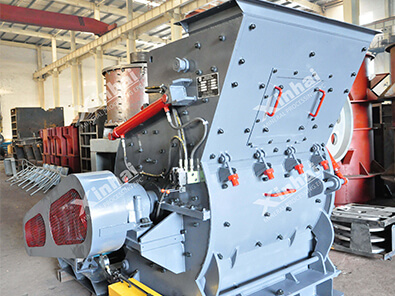

(A mobile crushing station from Xinhai is displayed)

01 Definition of Mobile Crushing Stations

Back

Mobile crushing station is an important form of open-pit mine crushing station. It is to place the mobile crushing unit on the working level of the open pit, and as the stripping face advances and the mining extends down to a certain distance, the mobile crushing unit is moved as a whole by crawler trucks and other traction equipment.

The mobile crushing station has feeding, crushing and unloading devices. The process flow is: after the blasting of the stripping working face, the rock excavator is loaded into a car, transported to the unloading and feeding device of the mobile crushing station in the stope, and then enters the crusher system for coarse crushing. The crushed qualified ore is transported to the processing plant and dumping site.

02 Classification of Mobile Crushing Stations

Back(1) Self-Propelled Mobile Crushing Stations

It has a walking mechanism. It works in the stripping working face and is directly fed by loading equipment (such as an excavator). When the stripping working face advances forward, it moves forward with the loading equipment. The frequency of displacement of the crusher depends on the advancing speed of the loading equipment. Because the crusher moves frequently, it is necessary to configure a belt conveyor system with a high degree of flexibility.

According to the walking mode, the self-propelled mobile crusher has a hydraulic wheel type, a rail wheel type, a tire type, a crawler type, and a stepping type. When selecting, comprehensive consideration should be given to the geological conditions of the mine, the load borne by the walking mechanism, the frequency of walking, the slope of the road, the location of the mining face, and the mining progress.

(2) Portable Crushing Stations

It can't move by itself, and needs to be equipped with special mobile equipment-crawler trucks or tire trucks. The transport vehicle can drive under the crusher, jack up the crusher with a hydraulic device, and move it to a new location. The crusher equipment is close to the center of the mining face in the stope. It can be moved every few months to several years as needed to keep a certain distance and height difference from the mining face.

03 Composition of Mobile Crushing Station

BackThe mobile crushing station is generally composed of three mutually independent parts, namely the crushing device, the feeding device, the unloading device, and also the maintenance device and the transportation device. Each of these three parts is an independent system, which is moved and set up with the help of a transport vehicle.

(1) Crushing Devices

The crushing device is the core equipment, which plays a decisive role in the production capacity of the unit. The mobile crusher adopts jaw type, gyratory type, jaw-gyratory type, hammer type, impact type and roller type. Choosing a crusher needs to comprehensively consider the production capacity of the mine, the nature of the ore, and the required product size.

There are some common rules about how to choose a crusher we need to know.

a. Jaw crushers and gyratory crushers are used for crushing hard rock generally;

b. Gyratory, jaw-gyratory, jaw, hammer and impact types are commonly used for crushing medium-hard ore;

c. Roller crushers are mostly used for crushing soft rock.

Generally, the gyrotary and jaw types are mostly used in portable crushers, while the hammer, impact, and roller types are mostly used in self-propelled crushers, so the production capacity is small, and they are mostly used in non-metallic mines such as limestone and coal mines. Most large metal mines use units with gyratory crushers as the main body.

(Brief introduction of Xinhai jaw crusher)

(2) Feeding Devices

The feeding device includes feeding equipment and receiving equipment. Feeding equipment is generally heavy-duty plate feeder, belt conveyor, chain feeder, disc feeder. In terms of consumption, heavy-duty plate feeder accounts for about 80%, and belt conveyors account for about 14%. The receiving equipment is generally a receiving bin and a funnel.

(3) Unloading Devices

The most commonly used unloading device is belt conveyor, accounting for about 74%; followed by slab conveyor, accounting for about 20%.

(4) Maintenance Devices and Transportation Devices

Maintenance equipment mainly includes lifting equipment and other maintenance equipment; transport devices are generally crawler-type.

04To Wrap Up

BackThis article mainly helps us understand the mobile crushing station through the definition, classification and composition of the mobile crushing station. It is an important method of mine crushing. You can click on this link to learn more about the crusher.

If you have any questions about this article, welcome to contact us.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now