Working Principle of 4 Commonly Used Crushers

Shirley

Shirley

Jan 14, 2022

Jan 14, 2022

4066

4066

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Crusher is an essential equipment in industry. Crushing operations are often divided into coarse crushing, medium crushing and fine crushing according to the size of feeding and discharging particles. Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc. This article will introduce the working principles of these four types of crushing machines one by one to help you choose the right crusher for your industry.

01 Jaw Crusher

BackJaw crushers are widely used in mining, smelting, building materials industry, highways, railways, water conservancy and chemical industries and many other sectors, crushing various materials with compressive strength within 320 MPa.

Working Principle

Jaw crusher mainly consists of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side guard plate, a toggle plate, a toggle plate rear seat, a clearance adjustment screw, a return spring, a fixed jaw plate and a movable jaw plate. And the bracket also plays a role in insurance.

The crushing method of the jaw crusher is a curved extrusion type. The motor drives the belt and pulley to make the movable jaw move up and down through the eccentric shaft.

When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate approaching to the fixed jaw, at the same time, the material is crushed.

When the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw under the action of the pull rod and spring. The jaw plate, at this time, the crushed materials are discharged from the lower mouth of the crushing cavity. With the continuous rotation of the motor, the crushing mobile jaw is periodically crushed and discharged to realize mass production.

02 Impact Crusher

BackImpact crusher can crush coarse, medium and fine mineral or rock (granite, limestone, concrete, etc.) with a particle size of less than 120-500 mm and a compressive strength of less than 320 MPa. It is widely used in hydropower, high-speed Highway, artificial sand and gravel crushing industries. The impact crusher has a unique structure, equipped with high chromium hammers and impact liners.

Impact crusher has the following advantages:

Suitable for hard rock crushing;

Discharging particle size is adjustable, which can simplify the crushing process;

High crushing efficiency and energy saving;

Large crushing ratio;

The product shape is cubic;

Selective crushing.

Working Principle

The impact crusher uses impact energy to crush materials. Driven by the electric motor, the rotor rotates at a high speed, and when the material enters the hammer action area, it will be crushed three times:

Collided with the hammer on the rotor and was crushed;

Being thrown onto the counterattack device and crushed;

Bounce back from the counterattack liner to the hammer action area and crushed.

The above process is repeated, and the materials from large to small enter the first, second, and third counterattack chambers to be repeatedly crushed until the materials are crushed to the required particle size and discharged from the discharge port. Adjusting the gap between the counterattack frame and the rotor can achieve the purpose of changing the size and shape of the material.

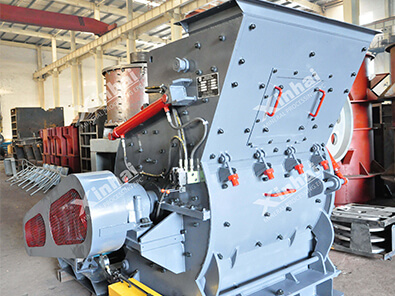

03 Hammer Crusher

BackHammer crusher is a kind of equipment for crushing materials in the form of impact. It is suitable for crushing medium hardness materials in cement, chemical industry, electric power, metallurgy and other industrial departments, such as limestone, slag, coke, coal and other materials in medium and fine crushing operations.

Working Principle

The hammer crusher crushes materials by impact. The crushing process is as follows:

The material enters the crusher and is crushed by the impact of the high-speed rotating hammer;

The crushed material obtains kinetic energy from the hammer head, and rushes to the baffle and screen in the frame at high speed. At the same time, the material collides with each other and is crushed continuously.

The materials smaller than the gap of the screen bar are discharged from the gap. Larger materials are continue to be crushed by the impact of hammer on the screen bar, and the fine material is squeezed out of the gap. So as to obtain the required particle size product.

04 Cone Crusher

BackCone crushers are widely used in mining industry, metallurgical industry, construction industry, road construction industry, chemical industry and silicate industry. They are suitable for crushing hard and medium hard ores and rocks, such as iron ore, limestone, copper ore, ,quartz , granite, sandstone, etc.

Working Principle

When the cone crusher is working, the motor drives the eccentric sleeve to rotate through the transmission device. The moving cone rotates and swings under the forced movement of the eccentric shaft sleeve. The section of the moving cone close to the static cone becomes the crushing cavity. The material is crushed by multiple extrusions and impacts of the moving cone and the static cone. When the moving cone leaves this section, the material that has been crushed to the required size will fall under its own gravity and be discharged from the bottom of the cone.

05To Wrap Up

BackThe above is an introduction to the working principles of 4 types of commonly used crushers. Which type of crusher to choose, also needs to be considered in combination with the hardness of the material, the particle size of the feed material, the required crushing particle size, and the processing capacity. When selecting crusher, it is recommended that you consult a professional crushing equipment manufacturer to select the most suitable one for your industry.

If you have any questions about the above issues or you want to get advice on crusher selection, please leave a message to communicate with us or consult our online customer service, we will contact you as soon as possible.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now