What Is Lepidolite and How is Lithium Extracted from It?

Laura

Laura

Apr 22, 2025

Apr 22, 2025

15

15

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

A thinckener in lithium ore processing plant

Lithium is the backbone of modern technology, powering everything from smartphones to electric vehicles (EVs). As the world shifts toward renewable energy, demand for lithium has skyrocketed, pushing the mining industry to explore alternative sources like lepidolite. But what exactly is lepidolite, and how do we extract lithium from this mineral? In this SEO-optimized guide, we'll simplify the science, processes, and challenges behind lepidolite-based lithium production.

01 What is Lepidolite?

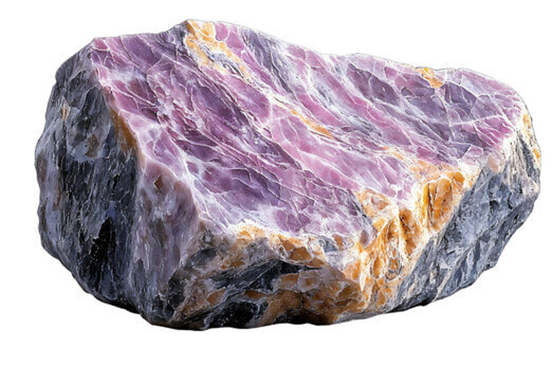

BackLepidolite is a lithium-bearing mineral belonging to the mica family. Known for its vibrant pink, purple, or gray coloration and flaky texture, it forms in granite pegmatites—coarse-grained igneous rocks. Its chemical formula, K(Li,Al)₃(Al,Si)₄O₁₀(F,OH)₂, reveals a mix of lithium, aluminum, potassium, and silicate, along with fluorine or hydroxide ions.

While lepidolite contains only 1.5% to 3.5% lithium oxide (Li₂O)—less than spodumene (6-8% Li₂O) or lithium-rich brines—it's increasingly mined in countries like Brazil, China, and Zimbabwe as a supplementary lithium source. More about spodumene vs lepidolite.

lepidolite ore

02 Why Mine Lepidolite for Lithium?

BackLepidolite isn't the most lithium-rich mineral, but it offers unique advantages:

Abundant Deposits: Often found alongside other lithium minerals, enabling multi-resource extraction.

Valuable Byproducts: Contains rare metals like rubidium and cesium, which can offset extraction costs.

Strategic Diversification: Reduces reliance on dominant lithium sources (e.g., Australian spodumene or South American brines).

lithium ball mill

03 How is Lithium Extracted from Lepidolite?

BackThe process involves two key stages: beneficiation (physically concentrating the ore) and chemical processing (extracting lithium compounds).

Stage 1: Beneficiation of Lepidolite Ore

Beneficiation upgrades the lithium content by removing impurities. Here’s a simplified breakdown:

1). Crushing and Grinding:

Raw lepidolite ore is crushed into smaller chunks and ground into a fine powder. This breaks down the mineral structure, freeing lithium-containing particles.

2). Froth Flotation:

The powdered ore is mixed with water and chemicals (e.g., collectors, frothers). Air bubbles are pumped into the mixture, causing lithium-rich lepidolite particles to attach to the bubbles and rise as froth. Impurities like quartz sink, allowing the froth to be skimmed off.

3). Drying and Concentration:

The froth is dried into a concentrated powder, boosting lithium oxide content to 4-6%. This concentrate is then ready for chemical processing.

lithium flotation cells

Stage 2: Chemical Processing to Extract Lithium

The concentrate undergoes complex chemical reactions to isolate lithium. The most common method is sulfuric acid roasting:

1). Roasting with Sulfuric Acid:

The lepidolite concentrate is mixed with concentrated sulfuric acid (H₂SO₄) and heated to 200–300°C. This breaks down the mineral structure, converting lithium into water-soluble lithium sulfate (Li₂SO₄).

2). Water Leaching:

The roasted material is dissolved in water, separating lithium sulfate from insoluble residues like silica and alumina.

3). Purification:

Impurities (e.g., iron, aluminum) are removed by adjusting the pH with lime or other neutralizing agents.

4). Lithium Carbonate Precipitation:

Sodium carbonate (soda ash) is added to the purified solution, triggering a reaction that crystallizes lithium into lithium carbonate (Li₂CO₃). This compound is further processed into lithium hydroxide (LiOH), the form used in lithium-ion batteries.

Alternative Extraction Methods:

Pressure Leaching: Uses high-pressure, high-temperature acid to dissolve lithium faster.

Bioleaching: Experimental techniques using bacteria to extract lithium, reducing chemical use.

04 Challenges of Extracting Lithium from Lepidolite

BackLow Lithium Content:

Processing more ore volumes to yield the same lithium quantity increases costs and energy use.

High Energy Demands:

Roasting and chemical treatments require significant energy, raising operational expenses and carbon footprints.

Toxic Byproducts:

Fluorine gas (released during roasting) and acidic waste must be carefully managed to avoid environmental harm.

Economic Viability:

Lepidolite projects often depend on byproduct sales (e.g., rubidium) to remain profitable.

05 The Role of Lepidolite in a Lithium-Driven Future

BackDespite challenges, lepidolite is gaining traction due to:

Geopolitical Diversification: Reduces reliance on major lithium-producing regions.

Technological Advances: Innovations in extraction efficiency and waste recycling.

Sustainability Efforts: Integration of renewable energy in processing plants to cut emissions.

cyclone for processing lithium

06 FAQs About Lepidolite and Lithium Extraction

BackQ: Is lepidolite used for anything besides lithium extraction?

A: Yes! It's sometimes used in ceramics, glass, and even jewelry due to its color.

Q: How does lepidolite compare to brine lithium sources?

A: Brines (e.g., in Chile) are cheaper to process but require arid climates. Lepidolite offers flexibility in mining locations.

Q: Is lepidolite mining environmentally friendly?

A: It has a higher environmental footprint than brines, but advancements in waste management and green energy are improving sustainability.

07Conclusion

BackLepidolite may not be the star of lithium mining, but it plays a critical supporting role in meeting global demand. As technology evolves, extracting lithium from this mineral could become cleaner and more efficient, supporting the transition to electric vehicles and renewable energy storage.

Feel free to contact us and learn more about lithium processing solutions!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now