Managing Mining Waste: Strategies for Environmental Sustainability and Regulatory Compliance

Essow

Essow

May 29, 2023

May 29, 2023

1263

1263

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Mining can have significant environmental impacts that can affect the surrounding ecosystems, water resources, air quality, and human health. Some of the environmental impacts of mining include:

Habitat Destruction: Mining activities can destroy natural habitats and disrupt ecosystems, leading to the loss of biodiversity and wildlife.

Water Pollution: Mining can contaminate water sources with toxic chemicals such as heavy metals, acids, and cyanide, which can harm aquatic life and make water resources unfit for human consumption.

Soil Erosion: Mining can cause soil erosion and sedimentation, which can lead to the loss of fertile soil and increased risk of floods.

Air Pollution: Mining can release dust, particulate matter, and other air pollutants, which can cause respiratory problems and other health issues for nearby communities.

There are several ways to mitigate the environmental impacts of mining, including:

Environmental Impact Assessments (EIAs): Conducting EIAs before mining operations to assess the potential impacts on the environment and to identify mitigation measures.

Proper Waste Management: Implementing proper waste management practices to prevent pollution of soil, water, and air.

Water Management: Implementing water management strategies to minimize the amount of water used in mining operations and to prevent contamination of water resources.

Reclamation and Restoration: Rehabilitating the land after mining operations are completed by restoring habitats, replanting vegetation, and stabilizing slopes to prevent soil erosion.

Use of Clean Technologies: Adopting clean technologiesand best practices to reduce the environmental impact of mining operations, such as using less toxic chemicals, reducing dust emissions, and using renewable energy sources.

Stakeholder Engagement: Engaging with local communities, indigenous peoples, and other stakeholders to ensure that their concerns and perspectives are taken into account in mining operations.

Compliance with Regulations: Complying with environmental regulations and standards to ensure that mining activities are conducted in a responsible and sustainable manner.

01 What are some of the challenges in implementing proper waste management practices in mining?

BackImplementing proper waste management practices in mining can be challenging due to several factors, including:

Cost: Implementing proper waste management practices can be expensive, and mining companies may be reluctant to invest in them, especially if they are not required by law.

Limited Space: Mining operations are often located in remote areas with limited space for waste disposal. This can make it challenging to find suitable locations for waste storage and disposal.

Complexity: Mining waste can be complex and difficult to manage due to its varying composition, size, and toxicity. Different types of waste require different management strategies, and it can be challenging to develop and implement effective waste management plans.

Regulations: Waste management regulations can vary widely between jurisdictions, and compliance can be complex and time-consuming. Some mining companies may be tempted to cut corners or ignore regulations to save time and money.

Community Resistance: Local communities may be resistant to waste management practices that they perceive as harmful to their health or the environment. This can lead to conflict and opposition to mining operations.

Long-Term Liability: Mining waste can be toxic and can remain hazardous for many years, even after mining operations have ceased. This can create long-term liability for mining companies, which may be responsible for managing and monitoring waste sites for decades or even centuries.

To address these challenges, mining companies can take several steps, such as:

Investing in Research and Development: Mining companies can invest in research and development to find new and innovativewaste management technologies and strategies that are more cost-effective and environmentally sustainable.

Collaborating with Communities: Engaging with local communities and stakeholders to understand their concerns and perspectives, and to develop waste management plans that are acceptable to them.

Prioritizing Safety: Prioritizing the safety of workers and the environment by implementing strict safety protocols, monitoring systems, and emergency response plans.

Compliance with Regulations: Complying with waste management regulations and standards to ensure that mining activities are conducted in a responsible and sustainable manner.

Long-Term Planning: Developing long-term waste management plans that take into account the potential long-term liabilities and risks associated with mining waste.

Education and Awareness: Educating workers, stakeholders, and the public about the importance of proper waste management practices and their role in ensuring a safe and sustainable mining industry.

02How can mining companies ensure that their waste management practices are environmentally sustainable?

BackTo ensure that their waste management practices are environmentally sustainable, mining companies can take several steps, including:

Conducting Environmental Impact Assessments (EIAs): Conducting EIAs before mining operations to assess the potential environmental impacts of waste generation and disposal and to identify mitigation measures.

Implementing Best Practices: Adopting best practices for waste management, such as reducing waste generation, reusing and recycling materials, and treating waste to minimize its environmental impact.

Using Clean Technologies: Using clean technologies to reduce the environmental impact of waste management, such as using renewable energy sources for waste treatment and disposal.

Monitoring and Reporting: Monitoring and reporting on waste generation, disposal, and environmental impacts to ensure that waste management practices are effective and to identify areas for improvement.

Engaging with Stakeholders: Engaging with local communities, indigenous peoples, and other stakeholders to ensure that their concerns and perspectives are taken into account in waste management practices.

Compliance with Regulations: Complying with waste management regulations and standards to ensure that mining activities are conducted in a responsible and sustainable manner.

Developing Long-Term Plans: Developing long-term waste management plans that take into account the potential long-term liabilities and risks associated with mining waste, such as the need for long-term monitoring and maintenance of waste disposal sites.

Prioritizing Safety: Prioritizing the safety of workers and the environment by implementing strict safety protocols, monitoring systems, and emergency response plans.

Investing inResearch and Development: Investing in research and development to find new and innovative waste management technologies and strategies that are more cost-effective and environmentally sustainable.

Continual Improvement: Continually reviewing and improving waste management practices to ensure that they are effective, efficient, and environmentally sustainable.

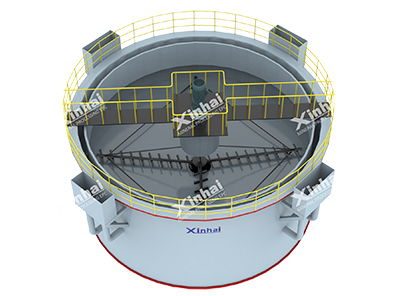

(Thickener to process tailings)

03How can mining companies ensure that their waste management practices are cost-effective?

BackMining companies can ensure that their waste management practices are cost-effective by taking several steps, including:

Reducing Waste Generation: Reducing waste generation by minimizing the use of materials and resources, optimizing processes, and implementing efficient production systems.

Reusing and Recycling Materials: Reusing and recycling materials to reduce waste generation and to recover valuable resources.

Treating Waste: Treating waste to minimize its volume and environmental impact, and to recover valuable resources.

Optimizing Waste Disposal: Optimizing waste disposal practices to minimize costs, such as selecting the most cost-effective disposal method and location, and optimizing waste transportation.

Investing in Research and Development: Investing in research and development to find new and innovative waste management technologies and strategies that are more cost-effective and environmentally sustainable.

Collaboration: Collaborating with other mining companies, waste management companies, and other stakeholders to share knowledge and resources and to develop more cost-effective waste management solutions.

Regulatory Compliance: Complying with waste management regulations and standards to avoid fines and penalties, and to minimize the risk of environmental liabilities.

Continuous Improvement: Continuously reviewing and improving waste management practices to identify areas for improvement and to optimize costs.

04How do mining companies ensure that their waste disposal methods comply with local regulations?

BackMining companies ensure that their waste disposal methods comply with local regulations by taking several steps, including:

Conducting Environmental Impact Assessments (EIAs): Conducting EIAs before mining operations to assess the potential environmental impacts of waste disposal and to identify mitigation measures to ensure compliance with local regulations.

Developing Waste Management Plans: Developing waste management plans that outline the waste disposal methods to be used, the monitoring and reporting requirements, and the compliance obligations.

Engaging with Regulatory Agencies: Engaging with regulatory agencies to understand the local regulations and to ensure that waste disposal methods comply with all applicable laws and regulations.

Obtaining Permits: Obtaining all necessary permits and approvals from regulatory agencies before implementing waste disposal methods.

Monitoring and Reporting: Monitoring waste disposal activities and reporting to regulatory agencies to demonstrate compliance with local regulations.

Continuous Improvement: Continuously reviewing and improving waste disposal methods to identify areas for improvement and to optimize compliance with local regulations.

Collaboration: Collaborating with other mining companies, waste management companies, and other stakeholders to share knowledge and resources and to develop more effective waste disposal methods that comply with local regulations.

05What are some common waste disposal methods used by mining companies?

BackMining companies use a variety of waste disposal methods depending on the type of waste generated, the location of the mine, and the local regulations. Some common waste disposal methods used by mining companies include:

Tailings Storage Facilities (TSFs): TSFs are large dams or impoundments that are used to store the waste materials generated by the mining process, such as the rock and sediment that remains after the ore has been extracted. TSFs are designed to prevent the release of contaminated water and to minimize the potential for erosion and slope instability.

Waste Rock Dumps: Waste rock dumps are areas where the non-ore-bearing materials, such as rock and soil, are deposited after they are removed during mining. Waste rock dumps are often located near the mine and are designed to minimize the potential for erosion and to prevent contamination of nearby water resources.

Heap Leach Pads: Heap leach pads are used to extract metals from low-grade ores by applying a chemical solution to the ore and allowing it to percolate through the material. The resulting solution is then collected and processed to recover the metals. Heap leach pads are designed to prevent the release of contaminated water and to minimize the potential for erosion and slope instability.

Underground Backfilling: Underground backfilling is the practice of using waste materials, such as tailings or waste rock, to fill voids or open spaces created by mining activities. Backfilling can help to stabilize the mine and to prevent subsidence, and it can also provide a safe and secure location for waste disposal.

Landfills: Landfills are used to dispose of non-hazardous waste materials, such as office waste, packaging materials, and non-toxic mine waste. Landfills are designed to prevent the release of contaminants into the environment and to minimize the potential for groundwater contamination.

Incineration: Incineration is the process of burning waste materials, such as hazardous waste or medical waste, at high temperatures to destroy or reduce their volume. Incineration is often used for waste materials that cannot be safely disposed of by other methods.

Recycling: Recycling is the process of reusing materials to reduce waste generation and to recover valuable resources. Mining companies can recycle materials such as scrap metal, used oil, and batteries to reduce waste and to recover valuable resources.

We have another article about waste dump construction, please click the link to check it.

06To Wrap Up

BackIn conclusion, waste management is a critical aspect of mining operations that can have significant environmental and social impacts on surrounding ecosystems and communities. Mining companies must adopt responsible and sustainable waste management practices to minimize these impacts and to comply with local regulations. To do so, mining companies can invest in research and development, implement best practices, use clean technologies, collaborate with stakeholders, comply with regulations, and continuously improve waste management practices. By taking a comprehensive and proactive approach to waste management, mining companies can minimize the environmental impact of their operations, protect the health and safety of nearby communities, and contribute to a more sustainable mining industry.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now