nickel-ore-flotation-plant

Nickel, a versatile and widely used metal, plays a crucial role in various industries, from stainless steel production to electric vehicle batteries. But have you ever wondered how nickel ore is extracted and transformed into the valuable metal we use every day? Let's dive into the fascinating world of nickel ore production and extraction.

01Exploration and Mining

BackThe journey of nickel begins deep underground. Skilled geologists explore vast areas to identify nickel rich ore deposits. Once a deposit is discovered, mining begins, and the ore is extracted using either open-pit or underground mining methods, depending on the depth and accessibility of the deposit.

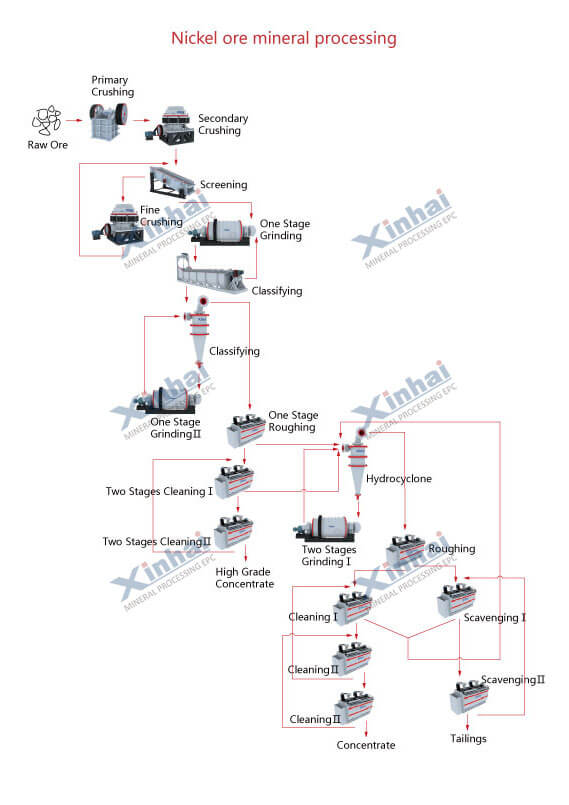

02Crushing and Grinding

BackAfter extraction, the nickel ore undergoes a series of processing steps to separate the valuable minerals from the waste rock. The first step is crushing the ore into smaller pieces, followed by grinding it into a fine powder. This increases the surface area of the ore, making it easier to separate the nickel minerals.

03Flotation and Magnetic Separation

BackThe next step in the extraction process is to separate the nickel minerals from the waste rock. This is typically done using flotation or magnetic separation techniques. In flotation, the ore is mixed with water and surfactants, and air is blown through the mixture, causing the nickel minerals to float to the surface. In magnetic separation, the ore is passed through a strong magnetic field, which attracts the nickel minerals, allowing them to be separated from the waste rock.

04Roasting and Smelting

BackOnce the nickel minerals have been separated, they are roasted at high temperatures to convert them into a more reactive form. This makes it easier to extract the nickel during the smelting process. In smelting, the roasted ore is heated with a reducing agent, such as coal or natural gas, to produce a molten nickel matte. This matte contains a mixture of nickel, copper, and sulfur.

05Refining

BackThe final step in the nickel production process is refining. The molten nickel matte is further processed to remove impurities, such as sulfur, copper, and iron. This is typically done through a process called electrolysis, where an electric current is passed through the molten nickel matte, causing the impurities to separate from the pure nickel.

06Conclusion

BackAnd there you have it! The nickel ore production and extraction process is a complex and fascinating journey that transforms raw ore into a valuable metal used in countless applications. As demand for nickel continues to grow, so does the need for efficient and sustainable extraction methods.

Explore our range of nickel products and discover how we can help you achieve your industrial goals. Contact us today to learn more about our nickel ore production and extraction processes!

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Sheena

Sheena  Mar 22, 2025

Mar 22, 2025 963

963 Message

Message Chat Now

Chat Now