Gold CIP Plant Prices: A Complete Guide

Laura

Laura

Mar 27, 2025

Mar 27, 2025

321

321

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Zimbabwe gold cip plant with 500tpd

The global gold mining industry relies heavily on efficient extraction methods like the Carbon in Pulp (CIP) process to recover gold from ore. This guide dives deep into CIP plant pricing, covering factors like capacity, technology, location, and hidden expenses. Whether you're a small-scale miner or a large mining corporation, this guide will help you budget wisely and maximize ROI.

01 What Is a Gold CIP Plant?

BackA Gold CIP (Carbon in Pulp) plant is a gold recovery system that uses activated carbon to extract gold from cyanide-leached ore. Here's a step-by-step breakdown of the process:

1. Ore Preparation: Crushing and grinding raw ore into a fine slurry.

2. Leaching: Mixing the slurry with a cyanide solution to dissolve gold.

3. Adsorption: Passing the gold-rich solution through activated carbon, which binds to gold particles.

4. Elution & Electrowinning: Stripping gold from the carbon and refining it into pure gold bars.

CIP plants are preferred for their high recovery rates (90–95%) and adaptability to low-grade ores. However, building and operating one requires significant capital and operational planning.

500kg desorption electrolysis system

02 Key Factors Influencing Gold CIP Plant Costs

Back1. Plant Capacity (Tonnes Per Day – TPD)

Capacity is the most significant cost driver. Larger plants benefit from economies of scale but require higher upfront investments.

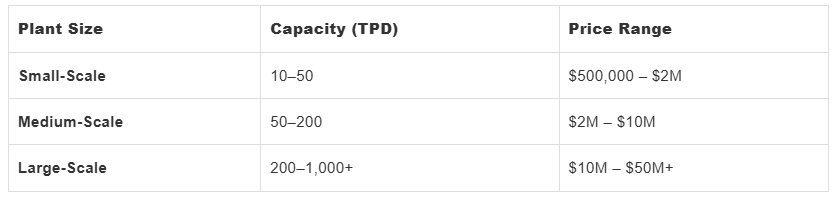

Prices for different capacity

Small-Scale Example: A 30 TPD plant in Ghana costs ~$1.5M, including basic leaching tanks and carbon columns.

Large-Scale Example: A 500 TPD plant in Australia costs ~$30M, featuring full automation and waste treatment systems.

2. Technology & Automation

Basic CIP Systems: Manual controls, standard carbon tanks, and basic pumps.

Advanced CIP Systems: Automated process controls, real-time monitoring, and energy-efficient designs.

Cost Impact: Advanced systems increase upfront costs by 20–40% but reduce labor and operational expenses long-term. For example, automated carbon regeneration systems can save $200,000/year in carbon replacement costs.

Gold CIP solutions

3. Location & Infrastructure

Remote Sites: Building in areas like the Amazon or Sahara Desert increases costs due to:

Transportation: Shipping heavy machinery via air or specialized trucks.

Infrastructure: Constructing roads, power grids, and water supply systems.

Labor Costs: Skilled technicians in remote regions may demand 20–50% higher wages.

4. Materials & Consumables

Activated Carbon: High-quality coconut-shell carbon costs $2,000–$5,000/ton. A medium-scale plant uses ~10 tons/month.

Cyanide: Sodium cyanide prices range $1,500–$3,000/ton, with strict safety protocols adding $100,000+ in handling infrastructure.

Steel & Construction: Volatile steel prices (up 30% since 2020) impact tank and pipeline costs.

5. Environmental & Regulatory Compliance

Tailings Management: Building tailings dams and water treatment systems costs $500,000–$2M.

Permitting: Environmental impact assessments (EIAs) and community consultations can take 6–18 months and cost $100,000–$500,000.

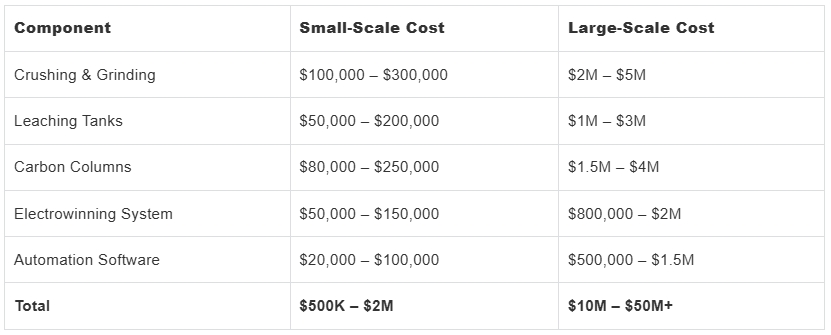

03 Detailed Price Breakdown by Component

Back

Detailed price breakdown by component in a CIP plant

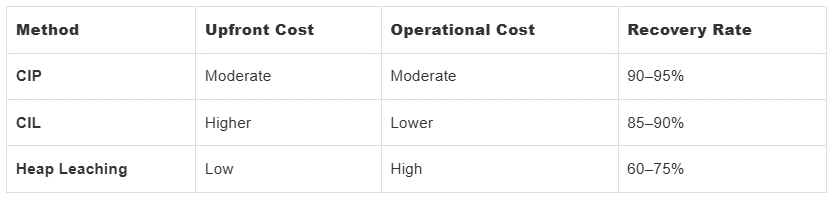

04 CIP vs. CIL vs. Heap Leaching: Cost Comparison

Back

CIP vs. CIL vs. Heap Leaching cost comparison

CIL (Carbon in Leach): Combines leaching and adsorption, reducing tank costs but requiring more carbon. 10–20% pricier than CIP. (Learn more about CIL process)

Heap Leaching: Cheaper upfront but less efficient, ideal for low-grade ores.

05 Hidden Costs of CIP Plants

Back1. Maintenance:

Carbon replacement: $50,000–$200,000/year.

Pump and valve repairs: $20,000–$100,000/year.

2. Energy Consumption:

Grinding and leaching consume 500–2,000 kWh/day, costing $100,000–$500,000/year.

3. Labor:

Requires 10–50+ workers, with annual wages totaling $1M–$5M.

4. Gold Losses:

Poorly optimized plants lose 5–10% of gold, equating to $500,000–$2M/year at current prices.

06 Case Studies: Real-World CIP Plant Costs

BackCase 1: Small-Scale CIP Plant in Tanzania

Capacity: 20 TPD

Cost: $1.2M

Components: Basic leaching tanks, manual carbon columns, and a small electrowinning unit.

Challenges: High transportation costs due to remote location added $150,000.

Case 2: Large-Scale CIP Plant in Canada

Capacity: 800 TPD

Cost: $45M

Components: Full automation, onsite lab, and zero-discharge tailings system.

Savings: Energy-efficient design reduced power costs by 30% (~$300,000/year).

07 Tips to Reduce CIP Plant Costs

Back1. Opt for Modular Designs: Pre-fabricated modules cut construction time and costs by 15–30%.

2. Localize Supply Chains: Source steel, carbon, and chemicals regionally to save 10–20% on shipping.

3. Invest in Automation: Reduce labor costs and human error with automated controls.

4. Recycle Carbon: Install regeneration kilns to reuse carbon, saving $100,000+/year.

5. Negotiate Cyanide Contracts: Bulk purchasing agreements can lower cyanide costs by 10–15%.

6. Use Renewable Energy: Solar panels or hydropower reduce grid dependence and long-term energy bills.

08 FAQs About Gold CIP Plant Costs

BackQ: How long does it take to build a CIP plant?

A: Small plants take 6–12 months; large plants require 2–4 years (including permitting and construction).

Q: Are there financing options for CIP plants?

A: Yes! Banks and equipment lenders offer loans with 5–10% interest rates, often secured against gold reserves.

Q: How does ore grade affect costs?

A: Low-grade ores (<2g/ton) require processing more material, increasing energy and consumable costs by 20–40%.

09Conclusion

BackBuilding a Gold CIP plant costs between $500,000 and $50+ million, depending on scale, technology, and location. While the upfront investment is substantial, CIP plants offer unmatched gold recovery rates and long-term profitability. To succeed, prioritize energy efficiency, partner with reputable suppliers, and budget rigorously for hidden operational costs.

Feel free to contact us and learn more about gold cip plant. Or maybe you can leave a message and we will reply to you soon!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now