Heap Leaching vs. Tank Leaching for Gold Extraction

Sheena

Sheena

Apr 19, 2025

Apr 19, 2025

16

16

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Site-map-of-the-Kazakhstan-gold-mine-heap-leaching-project

In the gold mining industry, choosing the right extraction method can significantly impact both operational efficiency and project economics. Two of the most widely used hydrometallurgical techniques for gold extraction are heap leaching and tank leaching (also known as agitation leaching). Each method has its advantages and limitations depending on ore type, project scale, and budget.

This article compares heap leaching vs. tank leaching in terms of process, cost, recovery rates, and suitability, helping mining companies, investors, and engineers make informed decisions.

01What is Heap Leaching?

BackHeap leaching is a low-cost, scalable method used to extract gold from low-grade ores. It involves stacking crushed ore on a prepared pad and applying a leaching solution—usually a cyanide solution—that percolates through the heap and dissolves the gold. The solution is collected at the bottom, and gold is recovered from the liquid.

Key Features:

Low capital cost

Ideal for large-scale, low-grade deposits

Slow processing time (months to years)

Simple design and low energy consumption

02What is Tank Leaching?

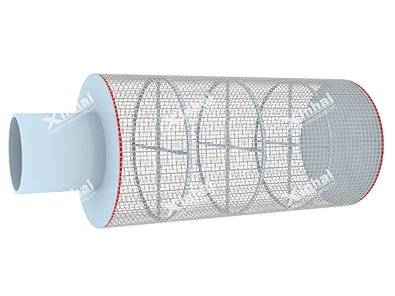

BackTank leaching (agitated leaching) is a more controlled process where finely ground ore is mixed with leaching solution in large tanks equipped with mechanical agitation. This method is commonly used for high-grade ores and offers faster recovery times.

Key Features:

Higher gold recovery rates (typically 90%+ for suitable ores)

Faster leaching process (hours to days)

Higher capital and operational costs

Requires more infrastructure and energy

03Heap Leaching vs. Tank Leaching: Side-by-Side Comparison

Back| Feature | Heap Leaching | Tank Leaching |

|---|---|---|

| Ore Grade | Low to medium | Medium to high |

| Capital Cost | Lower | Higher |

| Operating Cost | Lower per ton | Higher due to grinding and agitation |

| Recovery Rate | 50–85% (depends on ore type) | 85–95% (more consistent) |

| Processing Time | Weeks to months | Hours to days |

| Infrastructure | Simpler, open-air heaps | Complex, closed tank system |

| Environmental Controls | Requires lined pad and solution capture | Requires proper cyanide management and containment |

| Scalability | Excellent for large areas | Limited by tank volume and plant size |

04Which Leaching Method is Right for Your Project?

BackThe choice between heap leaching and tank leaching depends on several factors:

Ore Characteristics: Oxide ores with low-grade gold are better suited to heap leaching. Refractory or sulfide ores may require tank leaching or pre-treatment.

Project Budget: Heap leaching offers a lower upfront investment, making it attractive for junior mining companies or early-stage projects.

Timeline: If rapid gold recovery is a priority, tank leaching may be the better choice.

Environmental Considerations: Both methods require careful cyanide management, but tank leaching offers greater process control.

Contact us today to discuss your gold extraction needs and let our team recommend the right leaching solution for your operation.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now