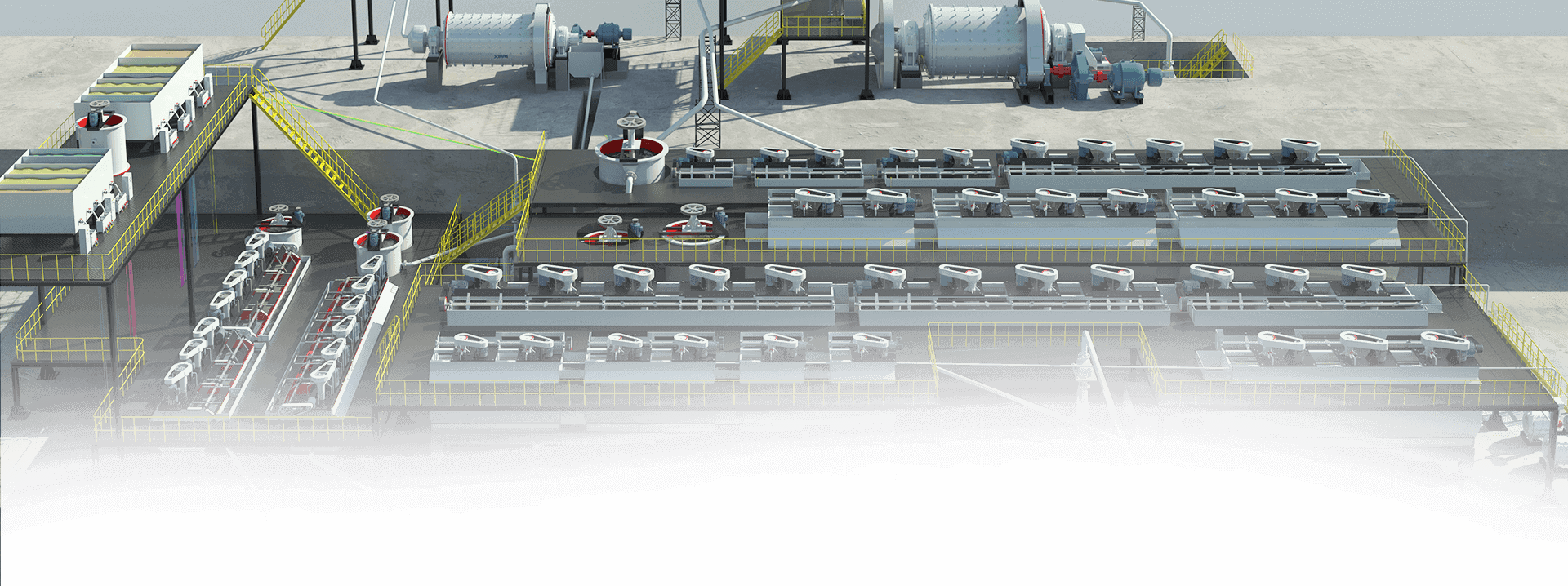

TYPICAL Mineral Processing Cases You Want to Know

Here we will give a breif introduction to typical mineral processing solutions we have carried out before. Each case will be explained with ore property, customized process, main machines and final results.

Hope you can find the typical mineral processing plant you want to know.

01 - China 4400TPD Copper Processing Plant

-

Ore Properties

The raw ore was high-sulfur Cu-S ore in the form of dense lump. Cu, S and Fe were closely associated. With Cu minerals being fine, the ore was of hard beneficiation.

-

Customized Solution

Flotation process of one-stage roughing, two-stage scavenging and three-stage concentration

-

Main Equipment

XCF Air Inflation Flotation Cell, KYF Air Inflation Flotation Cell, Overflow Type Ball Mill, Jaw Crusher, Magnetic Separator

-

Project Results

The final products were sulfur concentrates and copper concentrates. Comprehensive analysis showed that the project was relatively lucrative. The project fully tapped into the mineral resources and ensured environmental protection through solid waste recycling.

02 - China 3000TPD Lead-Zinc Tailings Dry Stacking Plant

-

Ore Properties

Lead and zinc are the main minerals.

-

Customized Solution

Flotation tailings adopted dewatering cyclone-dewatering screen-thickener-filter press.

-

Main Equipment

Hydrocyclone Unit, Press Filter, High Frequency Dewatering Screen, Efficient Thickener, Energy Saving Ball Mill

-

Project Results

The final water content of tailings dry stacking was lower than 15%. The service life of whole production line was twice as long as the common production line, which greatly reduced the artificial maintenance, and the operating costs were saved more than 2 yuan/ton at least.

03 - Pakistan 1500TPD Copper Processing Plant

-

Ore Properties

The raw ore was characterized by simple composition. It consisted of metallic minerals (copper pyrite and pyrite) and non-metallic minerals (quartz and chlorite). The Cu grade of the raw ore was 0.80%.

-

Customized Solution

Two- and half-stage closed-circuit crushing-one-stage closed-circuit grinding-flotation process of one-stage roughing, two-stage scavenging and two-stage concentration-two-stage mechanical dewatering

-

Main Equipment

Hydrocyclone, Press Filter, SF Flotation Cell, Overflow Type Ball Mill, Spring Cone Crusher

-

Project Results

The grade of copper concentrate was 20.78%, and the recovery rate of copper was up to 90.05%.

04 - Nigeria 1000TPD Gold-Copper Processing Plant

-

Ore Properties

Copper and gold are the main minerals.

-

Customized Solution

Two-stage semi-closed circuit crushing-continuous two-stage closed-circuit grinding-flotation process of one-stage roughing, three-stage scavenging and four-stage concentration-two-stage mechanical dewatering

-

Main Equipment

Efficient Improved Thickener, KYF Air Inflation Flotation Cell, Grid Type Ball Mill, Jaw Crusher

-

Project Results

After the raw ore was ground to -0.074mm (90%), copper concentrates were produced through the flotation process of one-stage roughing, three-stage scavenging and four-stage concentration. The concentrates had a Cu grade of 20.23%, a Cu recovery of 74.35%, an Au grade of 4.41g/t, an Au recovery of 75.66%, an Ag grade of 3,526.63g/t and an Ag recovery of 81.81%.

05 - Iran 500TPD Lead-Zinc Flotation Plant

-

Ore Properties

The raw ore of this project contained 3.68% of lead, 2.85% of lead in lead oxide, and 77.45% of lead oxidation; 16.06% of zinc, 15.93% of zinc in zinc oxide, and 99.20% of zinc oxidation.

-

Customized Solution

Two stage and one closed circuit crushing and screening - two stage closed circuit grinding - lead flotation (two roughing, one sweeping and four refining) - zinc flotation (two roughing, two sweeping and four refining) - dewatering process of lead and zinc concentrate.

-

Main Equipment

Hydrocyclone Unit, Efficient Thickener, Leaching Agitation Tank, KYF Air Inflation Flotation Cell, Overflow Type Ball Mill, Jaw Crusher

-

Project Results

The final products were lead concentrate and zinc concentrate. The grade of lead concentrate and zinc concentrate was 41.03% and 42.85% respectively.

06 - Myanmar 500tpd Copper Flotation Plant

-

Ore Properties

Copper is the main mineral.

-

Customized Solution

One-stage crushing-grinding and classifying-flotation (one-stage roughing, two-stage concentration and three-stage scavenging).

-

Main Equipment

Efficient Thickener, SF Flotation Cell, Submerged Spiral Classifier, Grid Type Ball Mill, Round Vibrating Screen, Spring Cone Crusher

-

Project Results

The project achieved the expected results.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Sheena

Sheena Jan 14, 2026

Jan 14, 2026