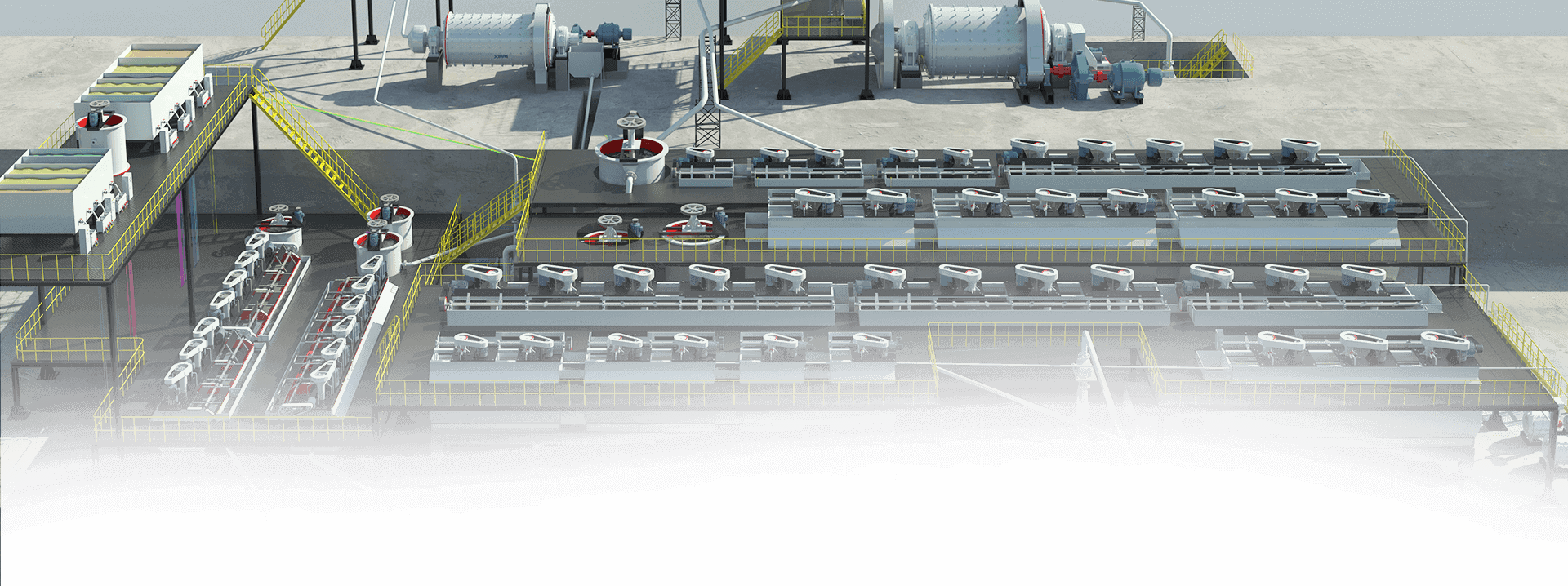

TYPICAL Mineral Processing Cases You Want to Know

Here we will give a breif introduction to typical mineral processing solutions we have carried out before. Each case will be explained with ore property, customized process, main machines and final results.

Hope you can find the typical mineral processing plant you want to know.

01 - Guinea 15000TPD Gold Processing Plant

-

Ore Properties

Oxidized gold ore. 80% of which is powdery clay ore, with an average grade of 1.0g/t. Gold is the only recoverable element, and the ore is easy to select.

-

Customized Solution

Raw ore feeding - grinding and classification - gravity separation - cyanide leaching - desorption electrolysis process.

-

Main Equipment

Hydrocyclone Unit, Hydrocyclone, Centrifugal Separator, Activated Carbon Regenerator, Pregnant Solution Purification Tank, Press Filter, Ceramic Vacuum Filter, Drum Filter

-

Project Results

Comprehensive recovery rate of 90%.

02 - Laos 2000TPD Gold Cyanidion Plant

-

Ore Properties

Gold is the only recoverable element in the ore of this project, with a grade of 2.6g/t.

-

Customized Solution

Crushing and washing - pond leaching adsorption - desorption electrolysis system - activated carbon pickling regeneration - smelting.

-

Main Equipment

Hydrocyclone, Hydrocyclone Unit, Centrifugal Separator, Activated Carbon Regenerator, Pregnant Solution Purification Tank, Press Filter

-

Project Results

The recovery rate of gold ore is 87%-95%.

03 - Indonesia 700TPD Gold Processing Plant

-

Ore Properties

The raw ore contains organic carbon and inorganic carbon, and the graphite content is 2%. Gold is the only recoverable element in the ore of this project.

-

Customized Solution

Cyanidized carbon pulp (CIL) process.

-

Main Equipment

Overflow Type Ball Mill, Hydrocyclone Unit, Linear Vibrating Screen, Air Lifter, Leaching Agitation Tank

-

Project Results

The recovery rate of gold ore is 87%-95%.

04 - Nigeria 1000TPD Copper-gold Processing Plant

-

Ore Properties

Gold and copper are the main minerals.

-

Customized Solution

two-stage semi-one closed-circuit crushing - two consecutive closed-circuit grinding - one roughing, three sweeping, four flotation selection - two-stage mechanical dehydration process.

-

Main Equipment

Energy Saving Ball Mill, Jaw Crusher, SF Flotation Cell, Efficient Thickener

-

Project Results

The grade of copper concentrate reached 20.23% with a recovery rate of74.35% and the gold content was 4.41g/t with the recovery rate of 75.66% and the silver content was 3526.63g/t with the recovery rate of 81.81%.

05 - Sudan 700TPD Gold Processing Plant

-

Ore Properties

The ore contains 2.97g/t of gold, some of which are earthy minerals with a particle size of less than 2mm, and a small part of which is blocky, with a maximum particle size of 70mm.

-

Customized Solution

two-stage one closed-circuit crushing and screening - two-stage fully closed-circuit grinding - cyanide leaching carbon adsorption - tailings pressure filtration - desorption electrolysis - smelting process flow.

-

Main Equipment

Hydrocyclone, Press Filter, Efficient Thickener, Leaching Agitation Tank, Energy Saving Ball Mill, Round Vibrating Screen, Jaw Crusher

-

Project Results

The commitment to the customer's "standards and productions" has been completed.

06 - Tanzania 600TPD Gold Mineral Processing Plant

-

Ore Properties

Very fine inlaid particle size. The single gold is less than or equal to 30%, and the particle size of most of the gold is less than 13μm.

-

Customized Solution

two-stage one closed-circuit crushing and screening - two-stage fully closed-circuit grinding - cyanide leaching carbon adsorption - tailings pressure filtration - desorption electrolysis system - smelting process flow.

-

Main Equipment

Hydrocyclone Unit, Ceramic Vacuum Filter, Zinc Powder Displacement Device, Desorption Electrolysis System, Leaching Agitation Tank, Energy Saving Ball Mill, Jaw Crusher

-

Project Results

The mixed ore contains Au 5.86g, the final gold leaching rate reaches 91.64%, and the carbon adsorption rate reaches 99.00%.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Laura

Laura Mar 27, 2025

Mar 27, 2025