TYPICAL Mineral Processing Cases You Want to Know

Here we will give a breif introduction to typical mineral processing solutions we have carried out before. Each case will be explained with ore property, customized process, main machines and final results.

Hope you can find the typical mineral processing plant you want to know.

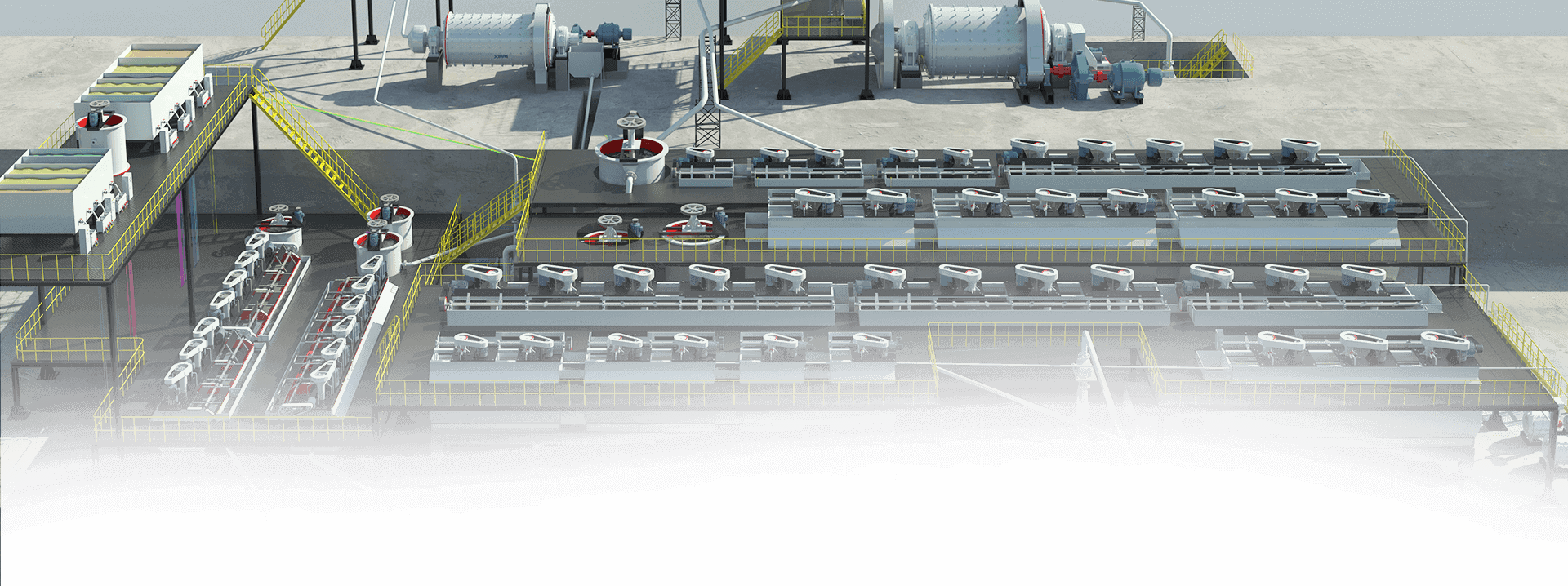

01 - Peru 5500TPD Copper-Iron Processing Plant

-

Ore Properties

The ore was of hard beneficiation because excessive fineness would make it harder for copper minerals to float, insufficient grinding would result in pool liberalization and copper and sulfur separation would affect the quality of iron concentrates.

-

Customized Solution

Two-stage closed-circuit crushing, closed-circuit grinding and two-stage classification, rapid flotation recovery of coarse copper minerals, flotation process of one-stage roughing, three-stage scavenging and four-stage concentration for fine copper minerals, and sulfur separation from tailings concentration and scavenging

-

Main Equipment

Hydrocyclone Unit, Ceramic Vacuum Filter, Efficient Improved Thickener, JJF Flotation Cell, Magnetic Separator, Energy Saving Ball Mill, Spring Cone Crusher

-

Project Results

While producing a great wealth of copper concentrates, iron concentrates and sulfur concentrates, the project created new job opportunities for local residents.

02 - China 3500TPD Iron Mining and Processing Plant

-

Ore Properties

The metallic minerals were magnetite, hematite, limonite; the non-metallic mineral was quartz. Only Fe in the raw ores has recycling value, and the raw ores belong to original acid magnetite with low phosphorus and low sulphur.

-

Customized Solution

Open-pit mining method, three-stage crushing and screening- stage-grinding and stage-separation- concentrates and tailings dewatering

-

Main Equipment

Hydrocyclone Unit, Ceramic Vacuum Filter, High Frequency Dewatering Screen, Magnetic Separator, High Dam Spiral Classifier, Overflow Type Ball Mill, Jaw Crusher

-

Project Results

The grade of first-stage iron concentrates was 65.06%, the yield of first-stage iron concentrates was 31.00%, the recovery of first-grade iron concentrates was 54.75%; the grade of second-stage iron concentrates was 51.95%, the yield of second-stage iron concentrates was 5.00%, the recovery of second-grade iron concentrates was 7.05%.

03 - China 2000TPD Iron Processing Plant

-

Ore Properties

The iron ore had high sulfur content.

-

Customized Solution

Grinding-magnetic separation - flotation process of one-stage roughing, two-stage scavenging

-

Main Equipment

Ceramic Vacuum Filter, XCF Air Inflation Flotation Cell, Magnetic Separator, High Dam Spiral Classifier, Overflow Type Ball Mill, Round Vibrating Screen

-

Project Results

The project achieved the desired effect.

04 - China 1200TPD Iron Processing Plant

-

Ore Properties

The iron ore properties were complicated.

-

Customized Solution

Two-stage closed-circuit crushing and screening-two-stage closed-circuit grinding and classification-magnetic separation process of one-stage roughing and three-stage concentration-concentrates and tailings filtering and dewatering

-

Main Equipment

Hydrocyclone Unit, Efficient Thickener, Magnetic Separator, Magenetic Drum, Submerged Spiral Classifier, Grid Type Ball Mill, Jaw Crusher

-

Project Results

The project adopted advanced, sound and energy-saving equipment and simple auxiliary facilities to cut construction costs and increase output. There was no environmental pollution, meaning that no waste water was discharged.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Sheena

Sheena Mar 12, 2025

Mar 12, 2025