Top 5 Gold Cyanidation Methods: Which One is Right for Your Operation?

Laura

Laura

Sep 11, 2024

Sep 11, 2024

742

742

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Guinea 3000tpd Gold Extraction Plant Project Site

Gold cyanidation is a critical process in the mining industry used to extract gold from ore. The method involves the use of cyanide, a highly toxic chemical, to dissolve gold and separate it from other minerals. Given the environmental concerns and regulatory challenges associated with cyanide use, selecting the right cyanidation method is essential for any operation looking to maximize efficiency while minimizing environmental impact. In this blog post, we will explore the top five gold cyanidation methods, detailing their advantages, disadvantages, and suitability for different types of operations.

01Heap Leaching

Back1. Overview

Heap leaching is a process where crushed ore is piled onto a lined pad, and a cyanide solution is applied to the surface. The cyanide seeps through the heap, dissolving gold as it percolates through the ore. The solution is then collected at the bottom and processed to extract the gold.

2. Advantages

- **Cost-Effective**: Heap leaching requires lower capital investment than other methods, making it a popular choice for small to medium-sized operations.

- **Simplicity**: The process is relatively straightforward and can be conducted with minimal technical expertise.

- **Flexibility**: It can be applied to various ore types, including low-grade ores, which may not be economically viable for other methods.

3. Disadvantages

- **Long Processing Time**: The leaching process can take several months to complete, which may delay returns on investment.

- **Environmental Concerns**: If not managed properly, heap leaching can lead to contamination of groundwater and surrounding areas.

- **Limited Recovery Rates**: While heap leaching can be effective, it often results in lower gold recovery rates compared to other methods, especially for more complex ores.

4. Suitability

Heap leaching is ideal for operations with low-grade ores and a desire to minimize upfront capital costs. It is particularly well-suited for remote locations where traditional milling and processing facilities are not feasible.

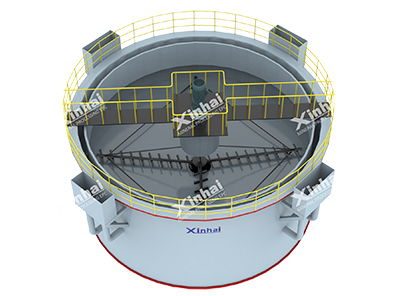

02Carbon in Pulp (CIP)

Back1. Overview

Carbon in pulp (CIP) is a process where finely ground ore is mixed with cyanide solution and activated carbon. The gold dissolves in the cyanide solution, and the activated carbon adsorbs the gold from the solution. The loaded carbon is then treated to extract the gold.

2. Advantages

- **High Recovery Rates**: CIP is known for its ability to achieve high gold recovery rates, often exceeding 90%.

- **Rapid Processing**: The process is relatively quick, with gold extraction typically occurring within hours to days.

- **Scalability**: CIP systems can be scaled up to accommodate larger operations, making them suitable for both small and large-scale mining.

3. Disadvantages

- **Higher Capital Costs**: The initial investment for a CIP plant can be significant, particularly for the equipment required for carbon handling and processing.

- **Complexity**: The process requires more technical expertise and monitoring than simpler methods like heap leaching.

- **Cyanide Management**: Like all cyanidation methods, proper handling and disposal of cyanide are critical to prevent environmental contamination.

4. Suitability

CIP is best suited for operations with high-grade ores and the ability to invest in more advanced processing facilities. Its high recovery rates make it particularly attractive for larger mining operations looking to maximize profits.

03Carbon in Leach (CIL)

Back

1. Overview

Carbon in leach (CIL) is similar to CIP, but the carbon is introduced directly into the leaching tank instead of being added afterward. This allows for simultaneous leaching and adsorption, making the process more efficient.

2. Advantages

- **Efficiency**: CIL can achieve higher gold recoveries in a shorter time frame compared to CIP due to the simultaneous leaching and adsorption process.

- **Reduced Processing Time**: The combined process means that gold can be extracted more rapidly, often within hours.

- **Improved Gold Recovery**: CIL typically has better recovery rates for lower-grade ores compared to other cyanidation methods.

3. Disadvantages

- **Higher Capital Investment**: Similar to CIP, CIL systems require significant initial investment and operational costs.

- **Complexity**: The process requires careful management and monitoring to optimize leaching and adsorption conditions.

- **Cyanide Safety**: As with all cyanidation methods, proper safety measures must be in place to handle the toxic cyanide.

4. Suitability

CIL is suitable for operations with a mix of high and low-grade ores. Its efficiency and ability to handle lower-grade materials make it attractive for larger mining operations looking to optimize their processes.

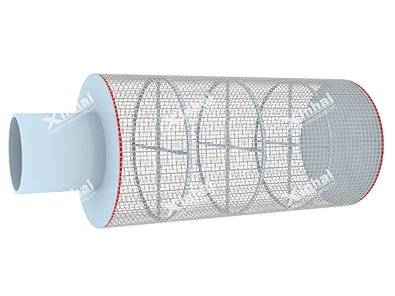

04Cyanide Leaching in Agitated Tanks

Back

1. Overview

In this method, ore is finely ground and mixed with a cyanide solution in agitated tanks. The agitation helps to increase the contact between the ore and cyanide, promoting faster dissolution of gold.

2. Advantages

- **Rapid Gold Recovery**: The agitation allows for quicker gold extraction, often within hours, leading to faster turnaround times.

- **High Recovery Rates**: This method can achieve very high recovery rates, especially for finely ground ores.

- **Control Over Process**: The ability to monitor and control the agitation and cyanide concentration allows for optimization of the leaching process.

3. Disadvantages

- **High Capital and Operating Costs**: The need for sophisticated equipment and constant monitoring leads to higher costs than simpler methods like heap leaching.

- **Technical Expertise Required**: This method requires skilled personnel to manage the process effectively.

- **Environmental Risks**: As with all cyanidation methods, there are significant environmental risks associated with cyanide use.

4. Suitability

Agitated tank leaching is best for operations with high-grade, finely ground ores. It is particularly effective for those looking to maximize recovery rates and minimize processing time.

05Bioleaching

Back1. Overview

Bioleaching is an innovative method that uses microorganisms to extract gold from ore. These microbes oxidize the sulfide minerals, releasing gold into solution, which can then be recovered using cyanidation or other methods.

2. Advantages

- **Environmentally Friendly**: Bioleaching is considered more environmentally friendly than traditional cyanidation methods, as it reduces the need for toxic chemicals.

- **Cost-Effective for Low-Grade Ores**: This method can be particularly effective for low-grade ores that are not economical to process using conventional methods.

- **Sustainable**: Bioleaching can use waste materials and is part of a more sustainable approach to mining.

3. Disadvantages

- **Longer Processing Time**: Bioleaching can take significantly longer than traditional methods, often requiring weeks or months to achieve desired recovery rates.

- **Microbial Control**: Maintaining optimal conditions for the microorganisms can be challenging and requires careful management.

- **Lower Recovery Rates**: Compared to conventional cyanidation methods, bioleaching may achieve lower recovery rates for some ore types.

4. Suitability

Bioleaching is ideal for operations focused on sustainability and those dealing with low-grade ores. Its environmental benefits may help mitigate regulatory challenges associated with cyanide use.

06Choosing the Right Method for Your Operation

BackSelecting the appropriate gold cyanidation method for your operation depends on various factors, including ore type, grade, environmental considerations, and financial resources. Here’s a summary to help you make an informed decision:

1. **Heap Leaching**: Best for low-grade ores and operations with limited capital. While it is cost-effective and straightforward, be mindful of potential environmental risks.

2. **Carbon in Pulp (CIP)**: Suitable for high-grade ores and operations that can invest in more advanced processing facilities. CIP offers high recovery rates but requires careful management of cyanide.

3. **Carbon in Leach (CIL)**: Ideal for operations with a mix of ore grades. CIL is efficient and offers high recovery rates, but it comes with higher capital costs.

4. **Cyanide Leaching in Agitated Tanks**: Best for high-grade, finely ground ores. This method provides rapid recovery but requires significant investment and technical expertise.

5. **Bioleaching**: A sustainable option for low-grade ores, reducing environmental impact. However, it involves longer processing times and may yield lower recovery rates.

Ultimately, the right choice will depend on your specific operational goals, regulatory environment, and commitment to sustainable practices. By carefully weighing the pros and cons of each method, you can make an informed decision that aligns with your operational needs and environmental responsibilities.

07To Sum Up

Back

As the mining industry continues to evolve, staying updated on advancements in cyanidation methods and technologies will be crucial for maintaining competitiveness and ensuring responsible resource extraction. Whether you prioritize cost-effectiveness, recovery rates, or environmental sustainability, there is a gold cyanidation method that can meet your operational objectives.

Contact us and learn more about Gold Cyanidation Methods.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now