Gold Processing Plant Costs: A Comprehensive Guide

Laura

Laura

Feb 27, 2025

Feb 27, 2025

373

373

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Myanmar 500tpd gold mine CIL plant project site )

When it comes to gold mining, understanding the costs associated with setting up and operating a gold processing plant is crucial for project viability and profitability. Whether you are a seasoned miner or a newcomer to the industry, having a detailed overview of these costs can help inform your decisions and strategies. In this comprehensive guide, we will explore the various factors that influence gold processing plant costs, providing you with the insights needed to navigate this complex landscape.

01 Introduction to Gold Processing Plants

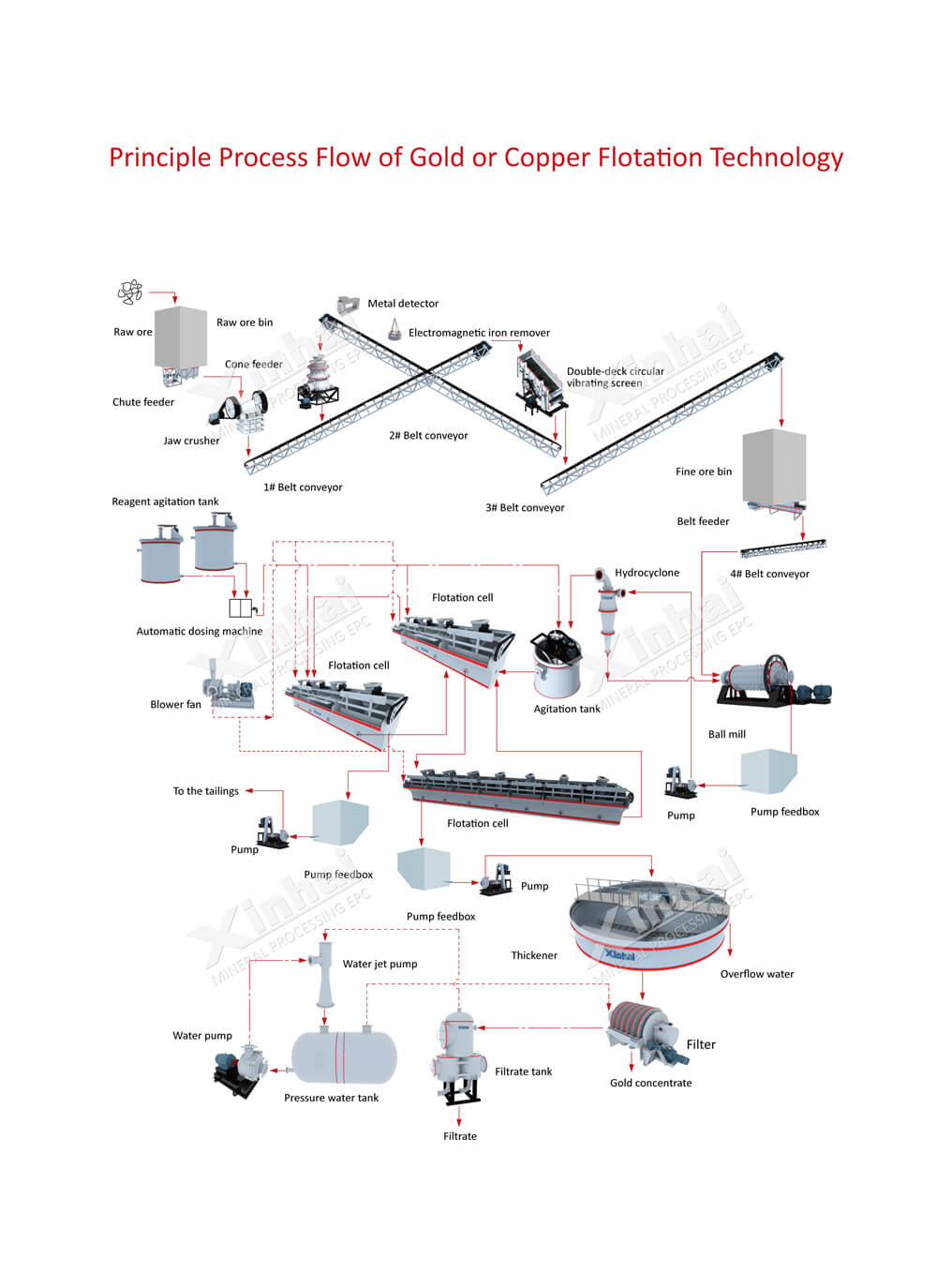

BackGold processing plants are facilities where gold is extracted from ore. The process typically involves several stages, including crushing, grinding, concentration, and refining. These stages require significant investment in equipment, technology, and labor, making it essential to understand the associated costs.

( Gold flotation process principles )

02 Key Factors Influencing Gold Processing Plant Costs

BackA. Location

The geographical location of your gold processing plant can significantly affect costs. Factors such as proximity to mining sites, access to transportation infrastructure, and local regulatory requirements can influence expenses related to logistics, permits, and labor.

B. Plant Capacity

The capacity of the processing plant, measured in tons of ore processed per day, directly impacts the initial investment and operational costs. Larger plants may benefit from economies of scale, but they also require more substantial upfront capital and ongoing maintenance.

C. Technology and Equipment

Investing in the latest technology and equipment can improve efficiency and recovery rates, but it also comes with higher costs. Common equipment used in gold processing includes crushers, grinders, flotation cells, and leaching tanks. Assessing the balance between cost and efficiency is critical when selecting the right technology for your plant.

D. Labor Costs

Labor costs can vary significantly based on location and the skill level required for various roles within the processing plant. In regions with a skilled workforce, labor costs may be higher, but the efficiency and expertise of workers can lead to increased production and lower overall costs.

E. Energy Costs

Gold processing is energy-intensive, with electricity being one of the largest operational expenses. Understanding local energy prices and exploring options for renewable energy can help mitigate these costs.

F. Regulatory Compliance

Compliance with environmental regulations and safety standards can add to the overall costs of operating a gold processing plant. This includes costs associated with obtaining permits, monitoring emissions, and ensuring worker safety.

03 Breakdown of Gold Processing Plant Costs

BackA. Initial Capital Expenditure (CapEx)

Initial CapEx includes the costs of land acquisition, construction, equipment purchase, and installation. Depending on the scale of the project, this can range from millions to billions of dollars.

B. Operational Expenditure (OpEx)

OpEx encompasses ongoing costs such as labor, maintenance, utilities, and consumables (e.g., chemicals). Monitoring these costs closely is essential for maintaining profitability.

C. Contingency Costs

It is wise to account for contingency costs, typically around 10-15% of the total budget, to cover unexpected expenses that may arise during the construction and operation phases.

04 Financial Analysis and Feasibility Studies

BackConducting a thorough financial analysis and feasibility study is crucial before embarking on a gold processing plant project. These studies should evaluate the total costs, projected revenues, and potential return on investment (ROI), helping stakeholders make informed decisions.

05 Strategies for Cost Reduction

BackA. Optimize Processes

Streamlining processing methods and adopting new technologies can enhance efficiency and reduce costs. Regularly reviewing and optimizing operational processes can lead to significant savings.

B. Negotiate Supplier Contracts

Building strong relationships with suppliers and negotiating favorable contracts can lead to cost reductions in equipment, materials, and services.

C. Invest in Training

Investing in employee training can lead to improved productivity and lower operational costs. A skilled workforce is more likely to operate equipment efficiently and adhere to safety protocols, reducing the risk of accidents and downtime.

06Conclusion

BackUnderstanding the costs associated with gold processing plants is vital for anyone involved in the gold mining industry. By considering factors such as location, capacity, technology, labor, energy, and regulatory compliance, stakeholders can make informed decisions that enhance profitability and project viability. Conducting thorough financial analyses and implementing cost-reduction strategies will further ensure the successful operation of a gold processing plant.

By following this comprehensive guide, you are better equipped to navigate the complexities of gold processing plant costs, paving the way for a successful venture in the gold mining industry. For further insights and updates, stay connected with industry news and trends.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now