How to Choose the Right Chrome Ore Beneficiation Process?

Laura

Laura

Dec 24, 2024

Dec 24, 2024

493

493

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Equipment operation of chrome ore flotation plant )

Choosing the right chrome ore beneficiation process is crucial for maximizing the efficiency and profitability of mining operations. Chrome ore, primarily composed of chromium, is vital for producing stainless steel and other alloys. With various beneficiation techniques available, selecting the most suitable process can significantly impact both the quality of the final product and the overall operational costs. In this article, we will explore the key factors to consider when choosing the right chrome ore beneficiation process.

01Understanding Chrome Ore Beneficiation

BackChrome ore beneficiation refers to the processes employed to improve the concentration of chrome within the ore. This typically involves several stages, including crushing, milling, classification, gravity separation, and sometimes flotation or magnetic separation. The goal is to produce a high-grade chrome concentrate that meets market specifications.

02Key Factors to Consider

BackWhen deciding on the appropriate chrome ore beneficiation process, several factors need to be evaluated:

1. Ore Characteristics

The first step is to analyze the characteristics of the chrome ore. Different ores have varying mineral compositions, textures, and physical properties, which can influence the choice of beneficiation methods. Key characteristics to assess include:

Mineralogy: Understanding the mineral composition helps in selecting the right separation techniques. For instance, ores with significant amounts of silicate minerals may require different processing methods compared to those primarily composed of chromite.

Particle Size Distribution: The size of the ore particles impacts the efficiency of separation techniques. Fine particles may require specific flotation techniques, while coarser particles might be better suited for gravity separation.

2. Desired Product Quality

The specifications for the final chrome concentrate are another critical factor. Different applications demand different purity levels. For example:

High-Grade Concentrate: If the target is to produce a high-grade chrome concentrate for stainless steel production, processes that optimize the recovery of chromium while minimizing impurities are essential.

Intermediate Products: If the goal is to produce intermediate products for further processing, the chosen method may vary based on the required specifications.

3. Available Technology

The choice of technology plays a significant role in the beneficiation process. Various methods are available, and their suitability depends on the ore characteristics and desired product. Common technologies include:

1). Gravity Separation: This is one of the most widely used methods for chrome ore beneficiation. It exploits the differences in specific gravity between chrome ore and other minerals. Equipment such as jigs, spirals, and shaking tables are commonly used.

2). Flotation: Flotation is effective for ores with fine particle sizes and can be used when gravity separation is less effective. This method involves adding chemicals to create froth that selectively separates chrome from other minerals.

3). Magnetic Separation: In some cases, magnetic separation can be beneficial, especially for ores containing magnetic minerals. This method is less common for chrome but can be effective under certain conditions.

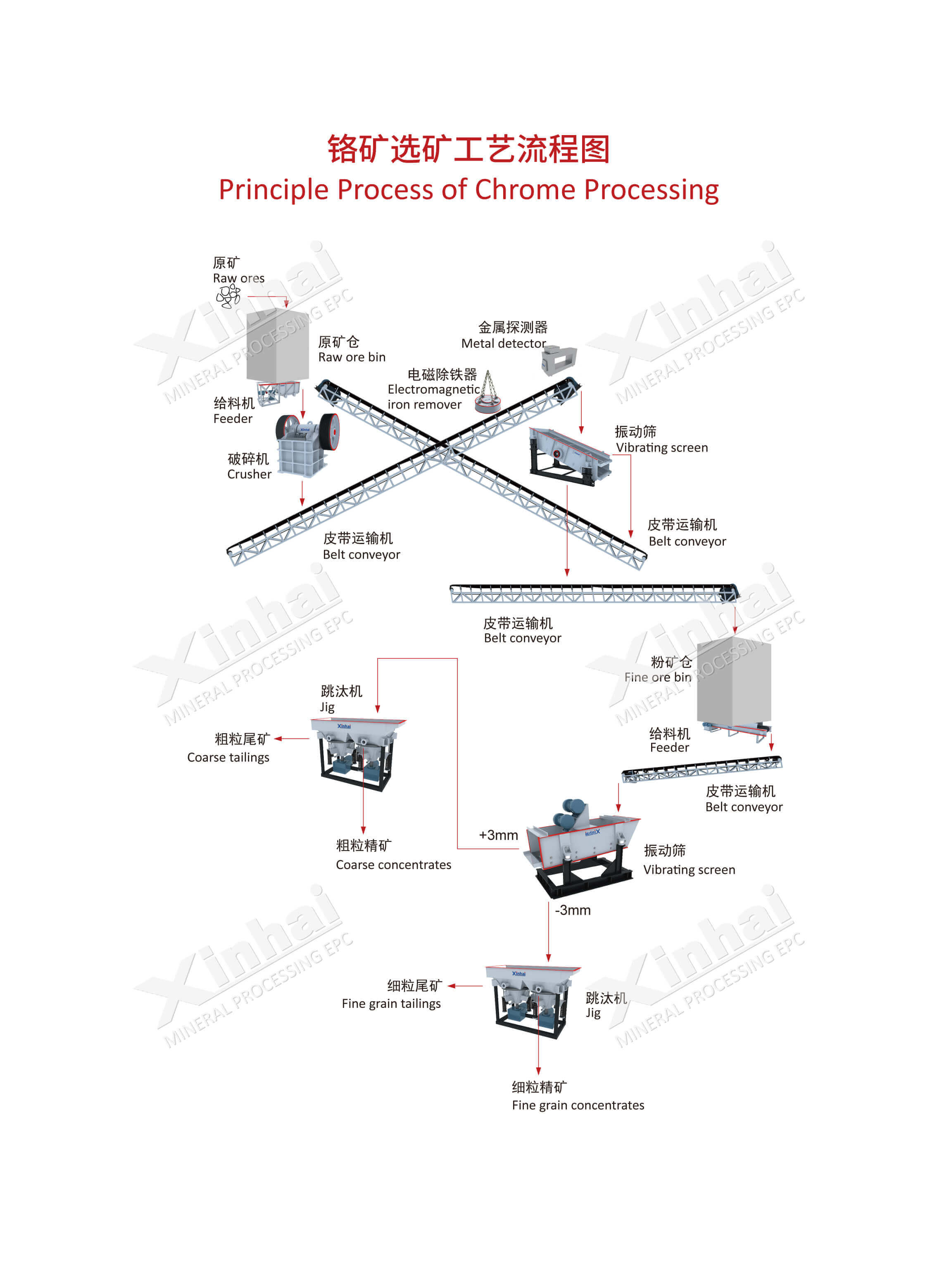

( Chrome ore dressing process flow chart )

4. Economic Considerations

Cost-effectiveness is a significant factor in deciding on the beneficiation process. This includes both the capital costs of equipment and the operational costs associated with running the beneficiation plant. Considerations include:

Initial Investment: The upfront costs for different processing technologies can vary widely. It's essential to balance the initial investment with the expected return on investment (ROI).

Operational Costs: Factors such as energy consumption, labor costs, and maintenance expenses must be evaluated to ensure that the chosen process is economically viable over the long term.

5. Environmental Impact

In today’s mining environment, sustainability and environmental impact are more important than ever. When choosing a chrome ore beneficiation process, consider the following:

Waste Management: The process chosen should minimize waste generation and ensure that any waste produced is managed responsibly.

Regulatory Compliance: Ensure that the selected process adheres to local environmental regulations and standards. This may include emissions controls and waste disposal practices.

6. Scalability and Flexibility

The chosen beneficiation process should be scalable and flexible to adapt to changing market demands and ore characteristics. Consider:

Future Expansion: If there are plans to increase production in the future, the selected process should allow for easy scaling without significant additional costs.

Adaptability: As ore quality and availability may change over time, the process should be adaptable to different ore types and grades.

03Conclusion

BackChoosing the right chrome ore beneficiation process is a critical decision that can significantly affect the success of mining operations. By carefully considering the ore characteristics, desired product quality, available technology, economic implications, environmental impact, and scalability, stakeholders can make informed choices that enhance operational efficiency and profitability. As the demand for chrome continues to grow, investing in the right beneficiation process will be key to meeting market needs while maintaining sustainable practices.

Contact us and learn more about chrome ore beneficiation process!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now