Silica Sand Processing You Should Know in 2024

Chileen Gao

Chileen Gao

Jan 11, 2023

Jan 11, 2023

1303

1303

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

(quartz sand purification)

Quartz is an important industrial mineral raw material with a wide range of applications. It can be used in glass, ceramics, metallurgy, casting, construction, chemical industry, refractory materials and other industrial fields. This article introduces the nature of quartz, mineral processing and purification methods and mineral processing equipment for your understanding.

01What is Quartz?

Back

Quartz, also known as silica, it refers to quartz sandstone, silica rock and vein quartz, etc. that meet industrial standards. Quartz sand, also known as silica sand, refers to naturally occurring quartz sand and mineral sand of various grain sizes (artificial silica sand) crushed and processed from quartzite that meets industrial requirements. Quartz and quartz sand are generally referred to as siliceous raw materials.

02Properties of Quartz

Back

Quartz is a silicate mineral with a shelf-like structure and is the main mineral component of quartzite and quartz sand. Its colour is milky white or colourless in a translucent state and its Mohs hardness is 7-7.5. In addition, quartz is chemically stable, insoluble in acids (except HF) and slightly soluble in KOH solutions. Overall, quartz is a hard wearing, chemically stable silicate mineral.

03Mineral Processing and Purification of Quartz Sand

Back

The main harmful impurities in quartz sand are clay impurities (fine mud, etc.), various iron-bearing minerals as well as feldspar, mica and other heavy mineral impurities. Generally, washing, flotation, re-election, magnetic separation, photoelectric picking and chemical purification beneficiation and comprehensive beneficiation methods are used for separation.

Quartz Washing Process

What Is Quartz Washing?

The washing method includes mechanical scrubbing, ultrasonic scrubbing and desliming, and is suitable for quartz sand ores containing clay impurities and sand grains with film contamination on the surface.

Scrubbing-demuding removes the clay in the raw sand and impurities on the surface of the sand grains, and is a widely used auxiliary beneficiation method for general sand ore sorting.

In addition, the selective grinding method with scrubbing as the main purpose can make part of the weathering serious feldspar crushing, water washing to remove. Ultrasonic scrubbing method is through the role of ultrasonic waves, so that the mineral surface film iron stripping. This method scrubbing time is short and the effect of iron removal is better.

Quartz Washing Equipment

(washing machine for silica sand processing)

High Efficiency Agitated Scrubbing Machine

The equipment is a hexagonal tank with three layers of specially designed impellers for a better scrubbing effect.

Box Type Agitator Scrubbing Machine

The machine is a four-sided box-type tank with a double layer of specially designed impellers for a good scrubbing effect.

Spiral Trough Scrubbing Machine

This machine has a double spiral structure and scrubs Korean clay minerals particularly well.

Quartz Flotation Process

What Is Quartz Flotation?

With petroleum sulfonate as a trapping agent, iron-containing minerals in quartz sand can be flotation under pH 4~5; with amine cation as a trapping agent, mica in quartz sand can be flotation under pH 3~4; with HF as an adjusting agent, feldspar can be flotation under pH 2~3. After the 1970s, countries have developed "fluorine-free flotation process for silica sand". flotation process", and in the early 1990s, China successfully researched the "fluorine-free acid-free flotation process for silica sand", which has been applied in industry.

Quartz Flotation Equipment

(washing machine for silica sand processing)

SF Type Mechanical Stirring Flotation Machine

This type of flotation machine is a self-priming flotation machine, where the pulp is inflated and stirred by the impeller and stator, and the air is generally drawn in from the bottom of the flotation tank near the mechanical stirring device. The advantage is that the flotation machine can self-absorb air and pulp during operation, and can achieve self-flow when the middle ore returns, without the support of auxiliary equipment, less overall investment, easy to operate and maintain the equipment, but the inflatable volume is small, high electricity consumption and wear and tear.

The main features of the SF type mechanical agitator flotation machine are all on the impeller, with backward inclined double-sided blades, which can realize double circulation of the slurry in the tank, and can realize the function of suction and suction slurry by itself during operation, without pump return between operations. It can be used for roughing and sweeping of various metallic and non-metallic minerals in the processing plant, and is generally used in medium and large processing plants.

KYF Type Inflatable Agitator Flotation Machine

Although this type of flotation machine is equipped with an agitation device (impeller, stator), it still needs an external air blower to force the air in, because the agitation device only plays the role of agitating the pulp and distributing the airflow. In addition to an air pressure system, a pump is also required for the return of the ore.

The KYF inflatable agitator flotation machine has a U-shape design; the impeller cavity has a porous cylindrical distributor, which enables the air to be evenly dispersed to most areas of the impeller blades in advance, giving sufficient space for pulp gas contact and improving flotation indexes. The flotation machine is not self-priming and cannot self-priming slurry, it needs to be equipped with a blower and a lifting pump. In mineral processing plants, the KYF type flotation machine is suitable for processing metal and non-metal ores with simple ore properties, doing roughing and sweeping operations, generally suitable for medium and large mineral processing plants.

Quartz Gravity Separation Process

What Is Quartz Gravity Separation?

Quartz gravity separation includes shaking table separation, gravity sedimentation, centrifugal sedimentation, hydraulic classification, spiral classification and so on.

The shaking table can remove iron minerals and other minerals in a granular state; hydraulic classification, spiral classification and other methods can be used to separate the raw sand into different grades to meet the requirements of industrial applications; spiral classification can also separate heavy metal minerals.

Quartz Gravity Separation Equipment

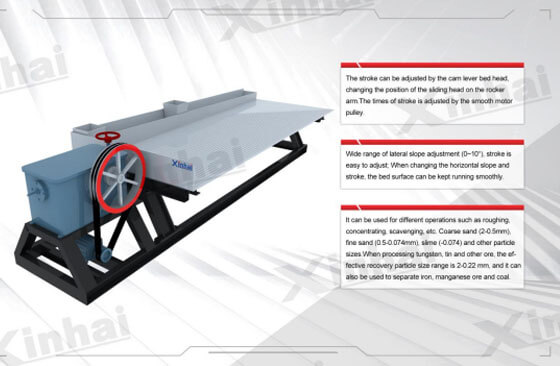

Shaking Table

According to the density and particle size of iron minerals, the shaking table is used to make the bed surface do longitudinal reciprocating motion, with the asymmetric reciprocating motion of the creation surface and the comprehensive effect of thin sloping water flow, so that the ore particles are fan-shaped distribution on the bed surface to achieve separation.

(shaking table for silica separation)

Jig Machine

The minerals are loosened by the pulsating vertical water flow, causing the incoming iron minerals to be stratified according to density, with the denser minerals sinking and being discharged from the bottom of the equipment and the less dense minerals being distributed in the upper layers and discharged with the overflow. The jigger is simple in structure, large in capacity, simple in operation and highly adaptable.

(jig for silica sand processing)

Spiral Chute

The spiral chute is based on the different specific gravity of the same minerals, since the slurry is fed, with the combined effect of water flow, gravity of minerals, friction between the grains and the bottom surface of the chute, the minerals are sunk according to the specific gravity, distributed in different areas of the chute, by the vertical running of the chute, and by the flow of water to complete the stratification, in which the smaller gravity of the grains in the rotary movement is thrown to the outer edge, the larger gravity of the grains in the inner edge of the chute movement.

(spiral chute for silica processing)

Centrifugal Concentrator

The centrifugal concentrator uses the combined action of gravity and centrifugal force to complete the sorting. With the slurry into the centrifugal concentrator, under the action of centrifugal force, heavy minerals are deposited on the inner wall of the drum and rotate with the drum, the light mineral particles in the slurry rotate with the drum at a certain differential speed, in the rotation process with a certain spiral angle from the feed end along the direction of the slope of the drum to the discharge end of the rotating flow, to the end of the discharge separator discharge, that is, the tailings.

(centrifugal separator for-quarzt purication)

Quartz Magnetic Separation Process

What Is Quartz Magnetic Separation?

The magnetic separation method can remove iron, various iron-containing minerals and other magnetic mineral particles entrapped in quartz powder.

The use of strong magnetic separators or high gradient magnetic separators, superconducting magnetic separators can remove weakly magnetic minerals and quartz particles containing inclusions of ferrous minerals and dipping bodies.

Quartz Stone Magnetic Separation Equipment

(magnetic machine for quartz processing)

Dry Type Magnetic Separator

The magnetic separator adopts 360° magnetic envelope angle design, the magnetic system all adopts high magnetic energy product, high coercivity NdFeB magnets, high magnetic field strength, large depth of action, magnetic field strength 8 years demagnetization rate does not exceed 5%.

Magnetic Roller

The machine is designed with a large magnetic envelope angle of < 180°, which increases the length of the separation belt and the number of magnetic reversals to achieve effective separation of magnetic and non-magnetic minerals.

Permanent Magnetic Cylinder Magnetic Separator

The magnetic system material of this equipment is selected for high performance, high coercivity, high remanence and NdFeB material with large depth of action; the surface of the cylinder can be lined with wear-resistant rubber.

Photoelectric Separation of Quartz

Photoelectric picking is a method of mechanical automatic picking and purification of quartz particles based on the difference in colour and lustre between the particles and other impurities. In China, this mechanical automatic sorting equipment is also known as a colour sorter. The sorting effect is related to particle size, dispersion and colour difference, and is generally suitable for sorting dry particles with relatively coarse particle size and significant colour differences.

Quartz Chemical Purification Process

Chemical purification methods include acid treatment, alkali treatment and salt treatment and gaseous hydrogen chloride treatment. Although the chemical treatment method is more costly. But in the treatment of crystal raw materials and processing of high-purity (SiO2 content required 99.95% or more, Fe2O3 and other impurities less than 10 × 10-6) quartz raw materials (alternative crystal), chemical treatment is one of the most effective methods, but also must be used.

04Summary

BackThe above is an introduction to the nature of quartz, processing methods and processing equipment. In the actual dressing, if you want to obtain the ideal grade of quartz, you need to decide the production process according to the nature of the ore, and must not copy and apply it. Beneficiation tests can be carried out first, and a suitable quartz sand production process can be tailored according to the test results. Click on the chat button to find out more about quartz purification.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now