What Is CIL in Gold Processing?

Laura

Laura

Mar 13, 2025

Mar 13, 2025

205

205

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Zimbabwe 200 tons CIL processing plant site

CIL, or Carbon in Leach, is one of the most efficient methods for extracting gold from ore in the mining industry. As gold continues to hold its value and importance in various sectors, understanding the processes involved in its extraction becomes essential for both industry professionals and investors. This article will delve into the intricacies of the CIL process, its advantages, and its significance in gold processing.

01 Understanding the CIL Process

BackThe CIL method involves a combination of leaching and adsorption processes to extract gold efficiently. Here’s a step-by-step breakdown of how CIL works:

1. Crushing and Grinding

The first step in the CIL process is the mechanical preparation of the ore. The gold ore is crushed into smaller fragments, which are then ground into a fine powder. This grinding process is critical because it liberates gold particles from the surrounding rock, increasing the surface area available for chemical reactions.

2. Leaching

After the ore is finely ground, it is mixed with a cyanide solution in large leaching tanks. The cyanide dissolves the gold present in the ore, forming a gold-cyanide complex. This leaching process typically takes several hours and is carefully monitored to ensure optimal conditions for gold dissolution.

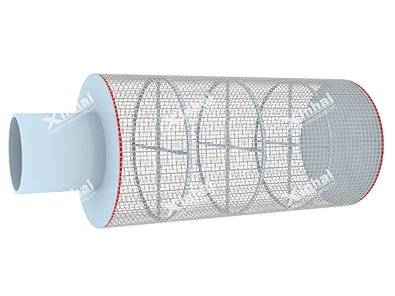

3. Carbon Addition

A key feature of the CIL process is the simultaneous addition of activated carbon to the leaching tanks. The activated carbon has a high affinity for gold and effectively adsorbs the gold-cyanide complex as it forms. This step is crucial because it allows for continuous recovery of gold during the leaching phase, differentiating CIL from the Carbon in Pulp (CIP) method, where carbon is added only after leaching.

(Welcome to learn more about gold CIP process)

4. Gold Adsorption

As the slurry moves through the tanks, the gold-cyanide complex binds to the activated carbon. This adsorption process is essential for separating gold from the solution, ensuring that valuable gold is captured effectively. The efficiency of this step is influenced by factors such as temperature, carbon concentration, and contact time.

5. Desorption

Once the activated carbon is saturated with gold, the next step is desorption, where the gold is stripped from the carbon. This is typically achieved using a hot caustic solution, which displaces the gold from the carbon, resulting in a concentrated gold solution.

6. Electrowinning

The concentrated gold solution is subjected to electrowinning, where an electric current is passed through it. This process causes the gold to precipitate onto cathodes, forming solid gold. The electrowinning phase is crucial for producing high-purity gold.

7. Refining

The final step in the CIL process is refining the precipitated gold. The solid gold is melted and purified through various chemical processes to produce high-quality gold bullion, suitable for sale in the market.

02 Advantages of CIL in Gold Processing

BackCIL is favored by many mining operations for several compelling reasons:

1. High Recovery Rates

CIL is renowned for its high gold recovery rates, often exceeding 90%. This efficiency is particularly beneficial for low-grade ores, where maximizing recovery is essential for profitability.

2. Cost-Effectiveness

Compared to other gold extraction methods, CIL is typically more cost-effective. The combination of leaching and adsorption reduces the need for additional equipment and chemicals, resulting in lower operational costs. Additionally, the effective use of cyanide minimizes wastage, further enhancing cost efficiency.

3. Simplicity and Automation

The CIL process is relatively straightforward and can be easily automated. This simplicity enables streamlined operations, reducing labor costs and minimizing the risk of human error. Automation also enhances process consistency, leading to more reliable outcomes.

4. Versatility

CIL can be used with a variety of gold ores, making it a versatile option for different mining contexts. It is particularly effective for ores that contain fine particles, which can be challenging to recover using traditional methods.

5. Environmental Considerations

While the use of cyanide in gold processing raises environmental concerns, advances in CIL technology have improved its safety and sustainability. Modern CIL systems often incorporate advanced monitoring and treatment systems to manage cyanide use responsibly and minimize environmental impacts.

03 Applications of CIL

BackCIL is particularly effective for processing gold ores with a grade of over 1 g/t and large bearing ore volumes.

It's also capable of extracting other valuable minerals such as silver, platinum, and copper that may be present in the ore. This makes it a versatile process in many gold - mining operations around the world.

04 CIL vs. Other Gold Processing Methods

BackUnderstanding the differences between CIL and other gold processing methods, such as CIP, is crucial for operators. While both methods aim to maximize gold recovery, the main distinction lies in the timing of carbon addition. In CIL, activated carbon is added during the leaching process, allowing for simultaneous adsorption of gold. In contrast, CIP requires carbon to be added after leaching, potentially leading to lower recovery rates in certain scenarios.

(Welcome to learn more about defference between CIL and CIP)

05Conclusion

BackCIL, or Carbon in Leach, is a vital method in the gold processing industry, offering high recovery rates, cost-effectiveness, and versatility. By combining leaching and adsorption into a single process, CIL enhances the efficiency of gold extraction, making it an attractive option for mining operations.

As the demand for gold continues to grow, understanding the CIL process will become increasingly important for professionals in the mining industry. Whether you are an investor, a mining engineer, or simply interested in gold processing, knowledge of the CIL method equips you with valuable insights into one of the most effective gold extraction techniques available today. Investing in CIL technology can lead to improved recovery rates and greater profitability in the competitive landscape of gold mining.

Feel free to contact us and learn more about gold CIL process! Or maybe you can leave a message and we will reply to you soon!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now