What Machines are Used for Lithium Mining?

Shirley

Shirley

Feb 01, 2024

Feb 01, 2024

2487

2487

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Lithium, a key component in rechargeable batteries and renewable energy storage systems, requires specialized machinery for its efficient extraction. This comprehensive guide explores the machines used in lithium mining, shedding light on the equipment and technologies employed to extract this valuable resource from various lithium-rich sources.

01Exploration and Site Preparation

BackBefore mining operations commence, exploration techniques are used to identify lithium-rich deposits. Once a suitable site is located, site preparation activities take place, including land clearing, infrastructure development, and geological surveys to ensure safe and efficient mining operations.

02Open-Pit Mining Equipment

Backa. Drilling Rigs: Drilling rigs are used to create boreholes for exploration and production purposes. They employ various drilling techniques, such as rotary drilling or core drilling, to extract rock samples and gather geological data.

b. Excavators and Loaders: These heavy machinery units are utilized in open-pit mining operations to remove overburden and extract lithium-bearing ore from the ground. Excavators are responsible for digging and loading the ore into haul trucks for transportation to the processing plant.

c. Haul Trucks: Large haul trucks, often with capacities ranging from 100 to 400 tons, transport the extracted lithium ore from the mining area to the processing plant. These trucks are designed to handle rough terrains and carry massive loads efficiently.

03Underground Mining Equipment

BackIn cases where lithium deposits are located at significant depths, underground mining methods are employed. The following machines are commonly used in underground lithium mining:

a. Shaft Sinking Equipment: Shaft sinking equipment, including drills and specialized machinery, is used to excavate vertical or inclined shafts for access to underground lithium deposits. These shafts allow miners and equipment to reach the lithium-rich zones safely.

b. Continuous Miners: Continuous miners are large machines equipped with cutting heads designed to extract lithium ore from the underground deposits. They are capable of cutting and loading the ore onto shuttle cars for transportation to the surface.

c. Shuttle Cars: Shuttle cars are used to transport the extracted lithium ore from the continuous miners to the underground storage or loading areas. These vehicles ensure efficient and timely transport within the underground mining environment.

04Crushing and Grinding Equipment

BackOnce the lithium ore is extracted from the mining site, it undergoes crushing and grinding processes to reduce its size and prepare it for further beneficiation. The following machines are commonly used in this stage:

a. Crushers: Crushers are used to break down large chunks of lithium ore into smaller, more manageable pieces. Jaw crushers, gyratory crushers, or cone crushers may be employed, depending on the specific requirements of the operation.

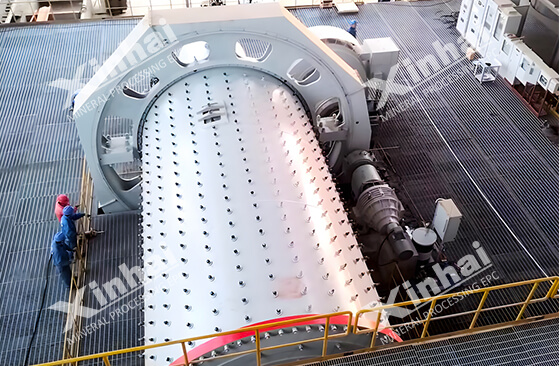

b. Grinding Mills: Grinding mills, such as ball mills or rod mills, are utilized to further reduce the size of the lithium ore through grinding. This process enhances the liberation of lithium minerals from the surrounding gangue materials.

05Beneficiation and Concentration Equipment

Backa. Flotation Cells: Flotation cells are commonly used in lithium ore beneficiation to separate lithium-bearing minerals from other non-valuable minerals. Through the use of reagents and air bubbles, the flotation process selectively separates and concentrates the lithium minerals.

06Lithium Recovery and Refining Equipment

Backa. Evaporation Ponds: In some lithium mining operations, evaporation ponds are used to extract lithium from brine deposits. These ponds allow solar evaporation to concentrate the lithium content, leading to its subsequent recovery.

b. Solvent Extraction and Electrolysis: For lithium recovery from brine or other solutions, solvent extraction and electrolysis techniques are employed. These processes involve separating and purifying the lithium through chemical reactions and electrolytic cells to obtain high-purity lithium compounds.

07To Wrap Up

BackThe mining of lithium requires a range of specialized machines and equipment to extract and process this valuable resource. From exploration and site preparation to open-pit or underground mining operations, crushing and grinding stages, beneficiation and concentration processes, and finally, lithium recovery and refining, each step involves specific machinery tailored to the requirements of the operation. By understanding the machines used in lithium mining, we can appreciate the complexity involved in harnessing this essential element and drive innovation in its extraction and utilization to meet the growing global demand for lithium-based technologies.

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now