Shaking Table Mineral Processing: A Comprehensive Guide

Laura

Laura

Feb 03, 2025

Feb 03, 2025

356

356

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Shaking tables in a chrome ore processing plant )

Shaking tables are a vital piece of equipment in the field of mineral processing. Known for their ability to separate and concentrate ores based on density and particle size, these tables are widely used in the mining industry. This comprehensive guide will explore the principles of shaking table mineral processing, its applications, advantages, and best practices for optimal performance.

01 What is a Shaking Table?

BackA shaking table, or wet table, is a gravity separation device that utilizes the differential movement of particles to separate valuable minerals from gangue. The table is inclined and vibrated, creating a shaking motion that causes denser materials to sink while lighter materials are carried away. This process relies on the principles of gravity and stratification, making it an effective method for mineral concentration.

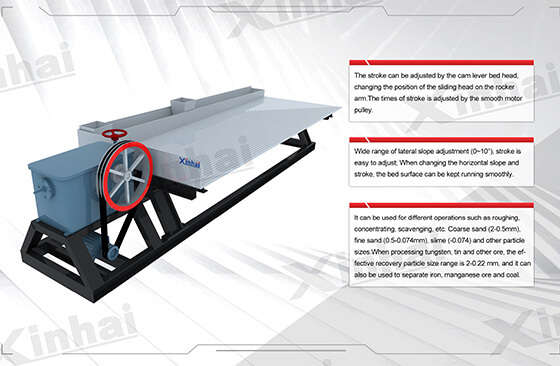

( Introduction of shaking table )

02 How Shaking Tables Work

BackThe operation of a shaking table involves several key components and processes:

1). Feed Preparation

Before the material is fed onto the shaking table, it must be crushed and ground to an appropriate size. This ensures that the particles are small enough to separate effectively.

2). Table Design

A typical shaking table consists of a flat surface with riffles (small grooves) that help trap heavier particles. The surface is usually coated with a material that enhances the separation process.

3). Vibration Mechanism

The table is set into motion by a mechanical or hydraulic vibration system. The shaking motion causes the material to move down the table while being stratified according to density.

4). Water Flow

Water is often introduced onto the table to facilitate the movement of fine particles and to assist in the separation of lighter materials. The flow rate can be adjusted to optimize the separation process.

5). Concentration and Collection

As the material moves down the table, heavier minerals settle into the riffles, while lighter materials are washed away. The separated products are then collected for further processing or refining.

03 Applications of Shaking Tables

BackShaking tables are used in various industries and for different types of minerals:

1). Precious Metals

They are commonly employed in the recovery of gold and silver from ores, as these metals are often found in low concentrations mixed with other minerals.

2). Base Metals

Shaking tables can also be used for separating copper, lead, and zinc ores, where they help improve the yield of valuable metals.

3). Rare Earth Elements

The tables are increasingly applied in the extraction of rare earth elements, which are critical for modern technologies.

4). Industrial Minerals

In addition to metals, shaking tables are used for the concentration of industrial minerals like tungsten and tin.

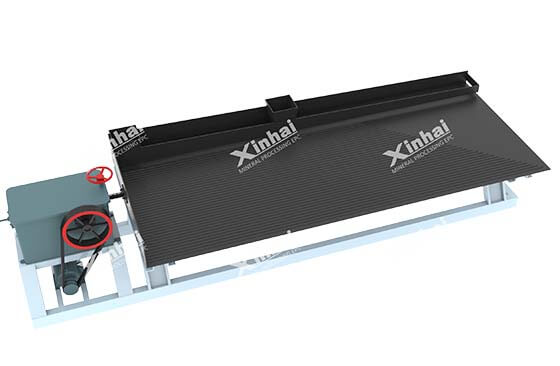

( Shaking table 3D )

04 Advantages of Shaking Table Mineral Processing

BackThe shaking table method offers several benefits that make it a preferred choice for mineral processing:

1). High Recovery Rates

Shaking tables are known for their ability to achieve high recovery rates of valuable minerals, making them an efficient option for ore concentration.

2). Cost-Effective

The operational costs associated with shaking tables are relatively low, especially compared to other separation methods. They require minimal maintenance and have a long lifespan.

3). Versatility

Shaking tables can process a wide range of materials, from fine to coarse particles, and can be adapted for various mineral types.

Minimal Environmental Impact: Unlike some chemical separation methods, shaking tables do not require hazardous chemicals, making them a more environmentally friendly option.

05 Best Practices for Optimal Performance

BackTo maximize the efficiency of shaking table mineral processing, operators should consider the following best practices:

1). Proper Feed Preparation

Ensuring that the ore is adequately crushed and ground is critical for effective separation. The optimal particle size should be determined based on the specific mineral being processed.

2). Adjusting Table Settings

Operators should regularly monitor and adjust the table's inclination, water flow rate, and vibration frequency. These parameters play a crucial role in optimizing the separation process.

3). Regular Maintenance

Routine maintenance of the shaking table is essential to prevent wear and tear. Regularly inspecting the table's surface and riffles can help maintain its efficiency.

4). Monitoring Recovery Rates

Tracking the recovery rates of valuable minerals can provide insights into the table's performance. Operators should analyze the concentrate and tailings to identify areas for improvement.

5). Training and Skill Development

Investing in training for personnel operating the shaking tables can significantly enhance operational efficiency. Skilled operators can make informed decisions to optimize the separation process.

06Conclusion

BackShaking table mineral processing is an effective method for separating and concentrating valuable minerals from ores. With their high recovery rates, cost-effectiveness, and versatility, shaking tables play a crucial role in the mining industry. By understanding the principles behind their operation and implementing best practices, mining companies can maximize the efficiency of their mineral processing efforts. As the demand for precious metals and other valuable minerals continues to grow, shaking tables will remain a vital tool in mineral processing operations worldwide.

Contact us and learn more about shaking table mineral processing!

+86 18716000713

+86 18716000713 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now